Flow photochemical reaction device

A photochemical reaction and flow technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of light source being difficult to replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

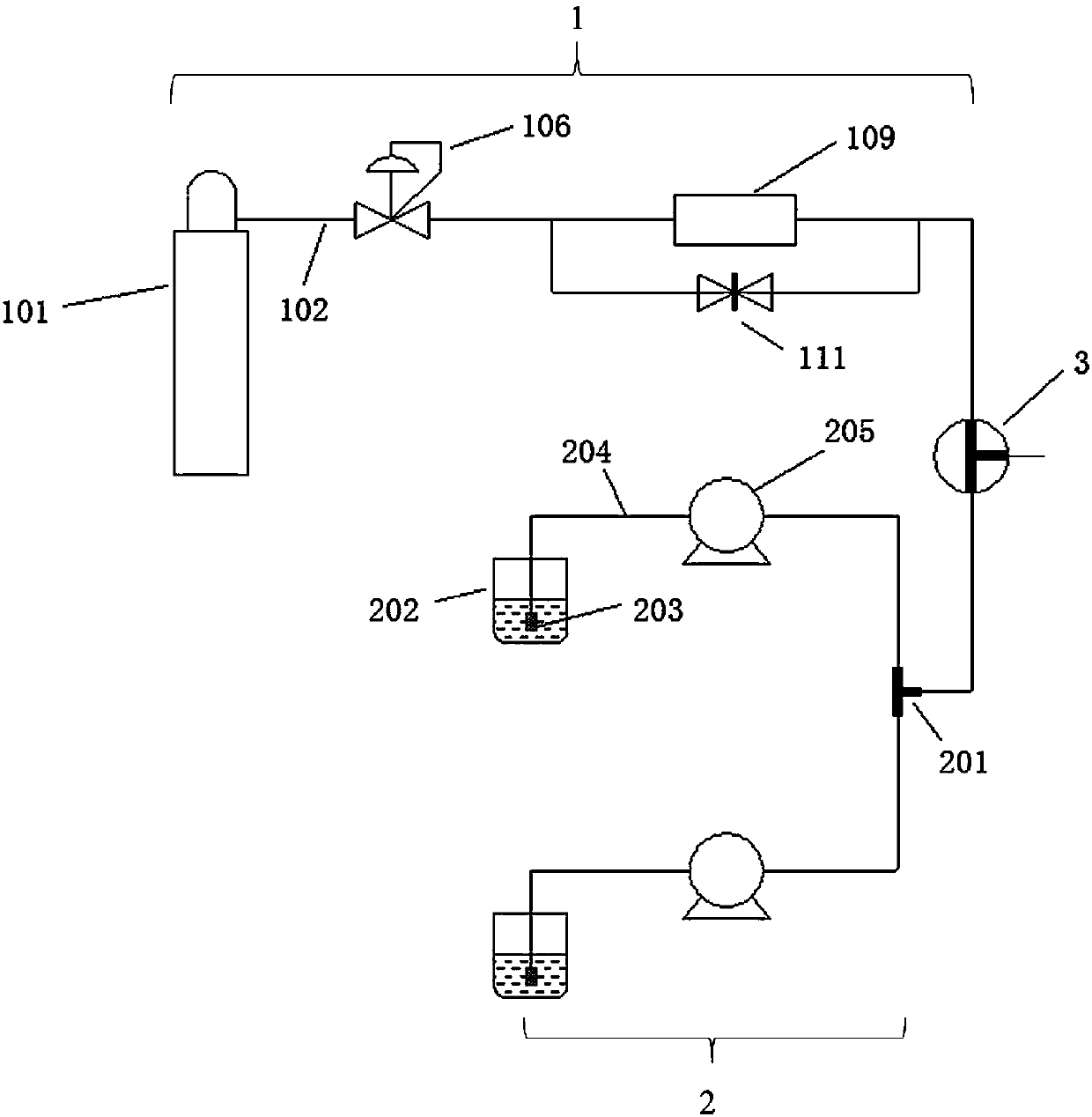

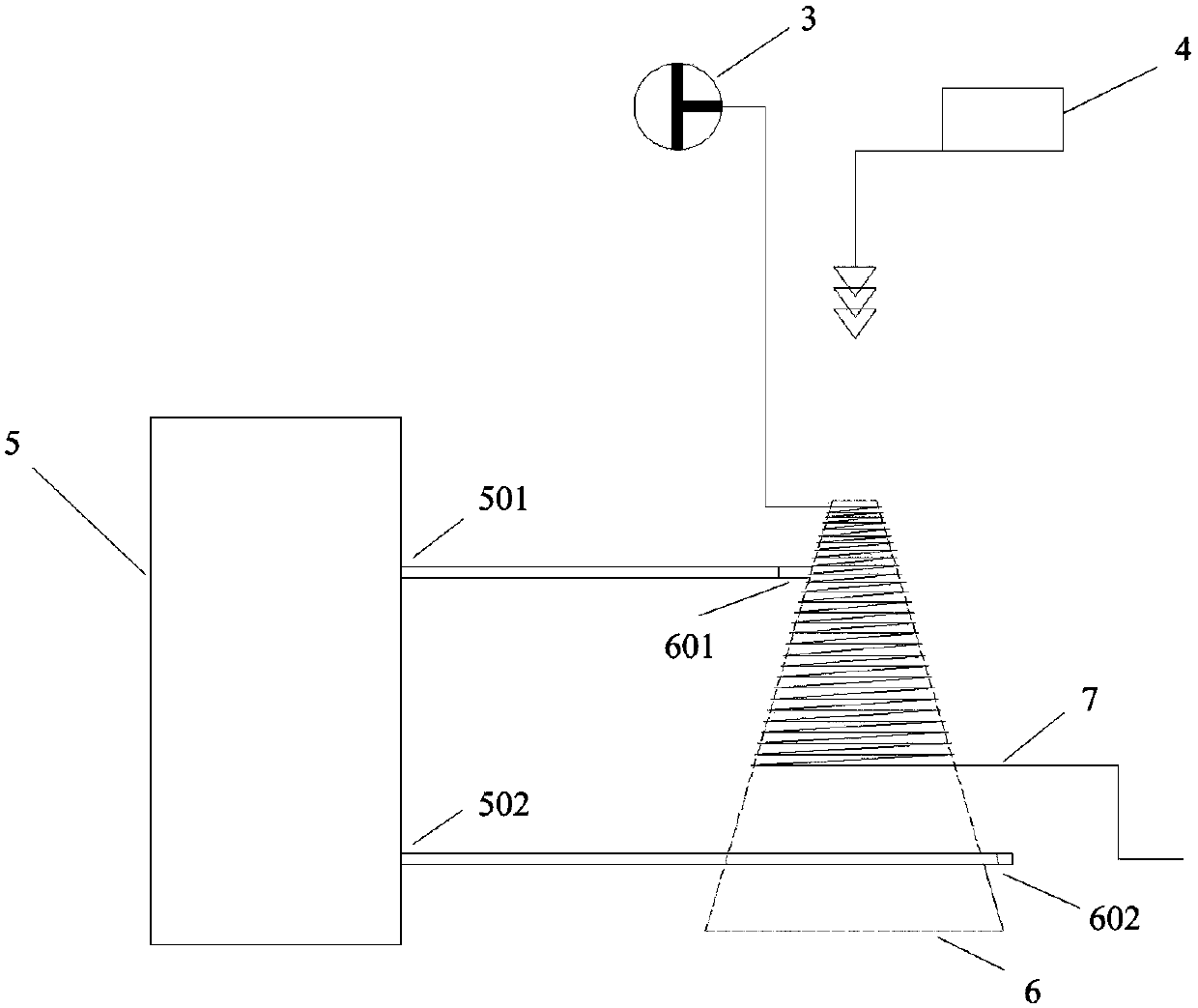

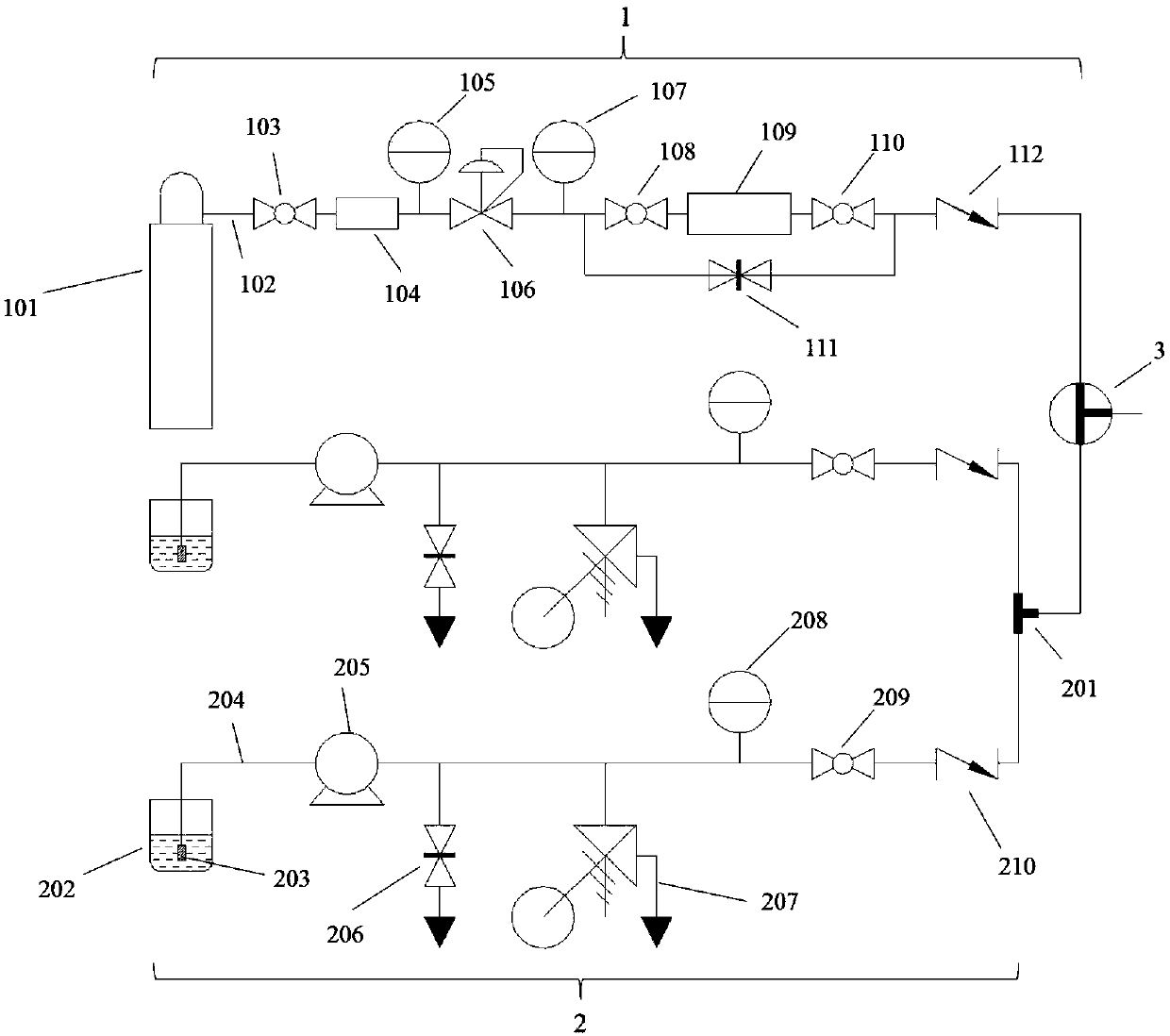

[0099] like Figure 1~2 As shown, the flow photochemical reaction device of this embodiment includes an air inlet system 1, a liquid inlet system 2, a micro-mixer 3, a light source 4, a constant temperature tank 5, a cold trap 6 and a micro flow tube 7 wound on the cold trap 6 ;

[0100] The inlet system 1 and the liquid inlet system 2 are connected to each other through the micro-mixer 3 and the micro-flow tube 7;

[0101] The cold trap 6 is a transparent glass closed container.

[0102] The cold trap 6 is set as a cone;

[0103] The light source 4 is located outside the cold trap 6 and arranged on the side of the vertex in the axial direction of the cold trap 6 . Setting the light source outside the cold trap is good for heat dissipation and uniform temperature.

[0104] The intake system 1 is a group, and the intake system 1 includes a gas cylinder 101, an air guide pipe 102, a pressure reducing valve 106, a gas mass flow meter 109 and a gas needle valve 112;

[0105] ...

Embodiment 2

[0125] like Figure 3-4 As shown, on the basis of Embodiment 1, the flow photochemical reaction device of this embodiment also includes a back pressure regulator 8 and a product collector 9. A collector 9 is connected, and the product collector 9 collects the product flowing out from the back pressure regulator 8 . The back pressure regulator 8 is composed of a pressure gauge 801 and a pressure reducing valve 802 connected in sequence, wherein the pressure gauge 801 has a range of 0-1Mpa and a minimum resolution range of 0.05Mpa. The back pressure regulator 8 maintains a certain pressure for the reaction system, which is beneficial to the dissolution of the gas in the liquid phase so as to speed up the reaction process.

[0126] The air intake system 1 of the flow photochemical reaction device of this embodiment also includes a gas filter, a gas pressure gauge, a gas check valve, a gas ball valve and a pressure reducing valve.

[0127] The air duct 102 of the air intake syst...

Embodiment 3

[0140] like Figure 5-6 As shown, the flow photochemical reaction device of this embodiment is based on the embodiment 2, and the cold trap 6 and the microfluidic tube 7 wound on the cold trap 6 are arranged in a protective box 10 . The direction of the cold trap 6 can be set as required, for example, the cone of the cold trap can stand vertically on the bottom of the box, or can be placed horizontally in the box.

[0141] The protective box 10 is made of stainless steel.

[0142] The protection box 10 is provided with a box door, and the box door is a sliding box door.

[0143] The protective box 10 is configured as a rectangular parallelepiped box.

[0144] The protective box 10 is provided with a temperature sensor 1001 , and the temperature probe of the temperature sensor 1001 extends into the protective box 10 and clings to the micro-flow tube 7 .

[0145] The protection box 10 is provided with a hole for the pipeline and the temperature probe of the temperature sensor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com