Nitrogen protection cleaning method for nanometer wafer product

A nitrogen protection, nanocrystalline technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as inability to clean nano-wafers, achieve increased effective spray radius, flexible use, Guaranteed cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

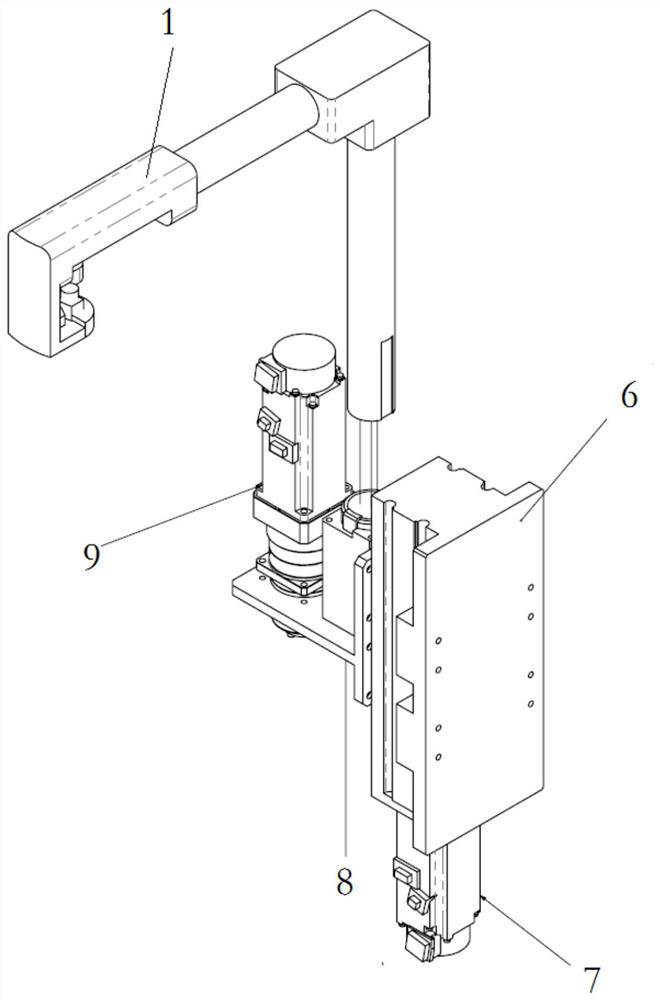

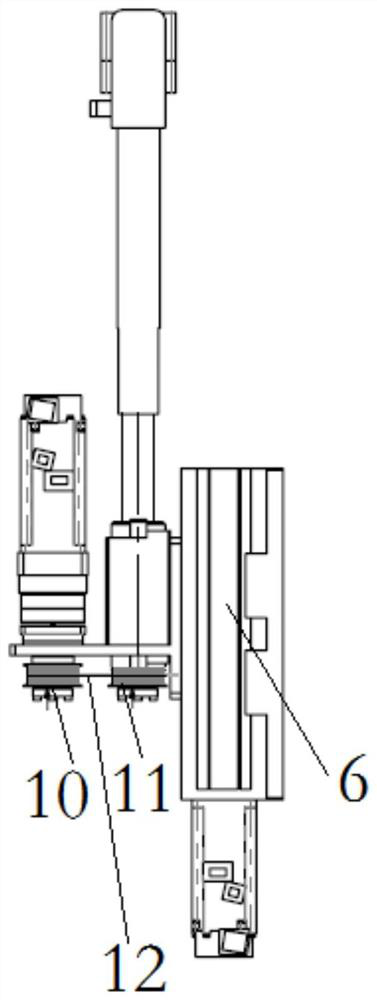

[0033] This embodiment provides a nitrogen protection cleaning device for nano-wafer products, including a wafer carrying mechanism and a wafer cleaning mechanism. Wherein, the wafer carrying mechanism is used to place the wafer, and the wafer can be fixed on the upper surface of the wafer carrying mechanism and rotated under the drive of the wafer carrying mechanism. The wafer carrying mechanism can be formed in various structures, for example, Bernoulli is used to adsorb the wafer on the surface of the wafer carrying mechanism. This part of the structure can be rotated by those skilled in the art according to the needs of use, and will not be repeated here.

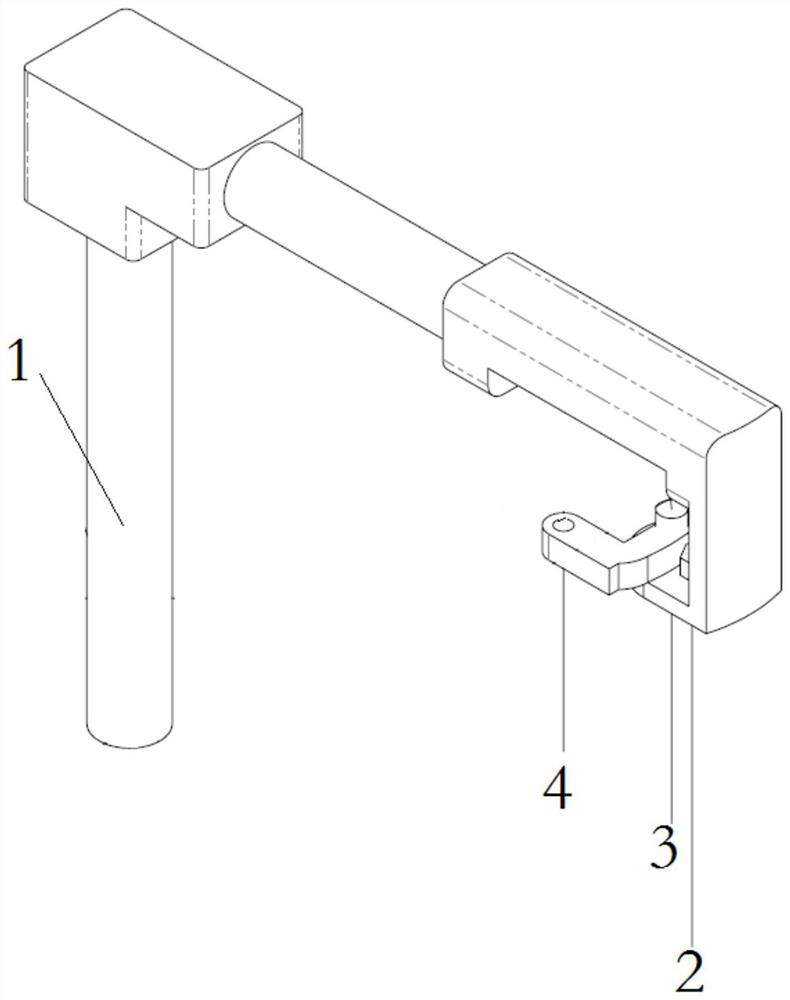

[0034] The wafer cleaning mechanism includes a driving mechanism, a cleaning shell 1, a liquid cleaning nozzle 3, an atomized cleaning nozzle 2, a nitrogen nozzle 4, and an ultrasonic vibration plate 5. One end of the cleaning shell 1 is arranged on one end of the wafer carrying mechanism, and the cleaning shell The bod...

Embodiment 2

[0039] This embodiment provides a method for cleaning nano-wafer products under nitrogen protection, comprising the following steps:

[0040] Step 1. Move the liquid cleaning nozzle 3, atomization cleaning nozzle 2, and nitrogen nozzle 4 directly above the wafer, and adjust the distance between the atomization cleaning nozzle 2 and the wafer to 14-30 mm; atomization cleaning The distance between the shower head 2 and the wafer decreases as the aperture on the surface of the wafer decreases;

[0041] Step 2: The wafer carrying mechanism drives the wafer to rotate, and the external gas source of the nitrogen nozzle 4 supplies gas, blows nitrogen to the surface of the wafer, and turns on the liquid cleaning nozzle 3 and the atomization cleaning nozzle 2 in turn, to the surface of the wafer. Spray the cleaning solution on the surface to clean the surface of the wafer;

[0042] Step 3: After the cleaning is completed, the atomization cleaning nozzle 2, the liquid cleaning nozzle 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com