Optical element defect inhibition equipment and method

A technology of optical components and equipment, applied in chemical instruments and methods, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve problems affecting components, surface contamination, and reducing component surface shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

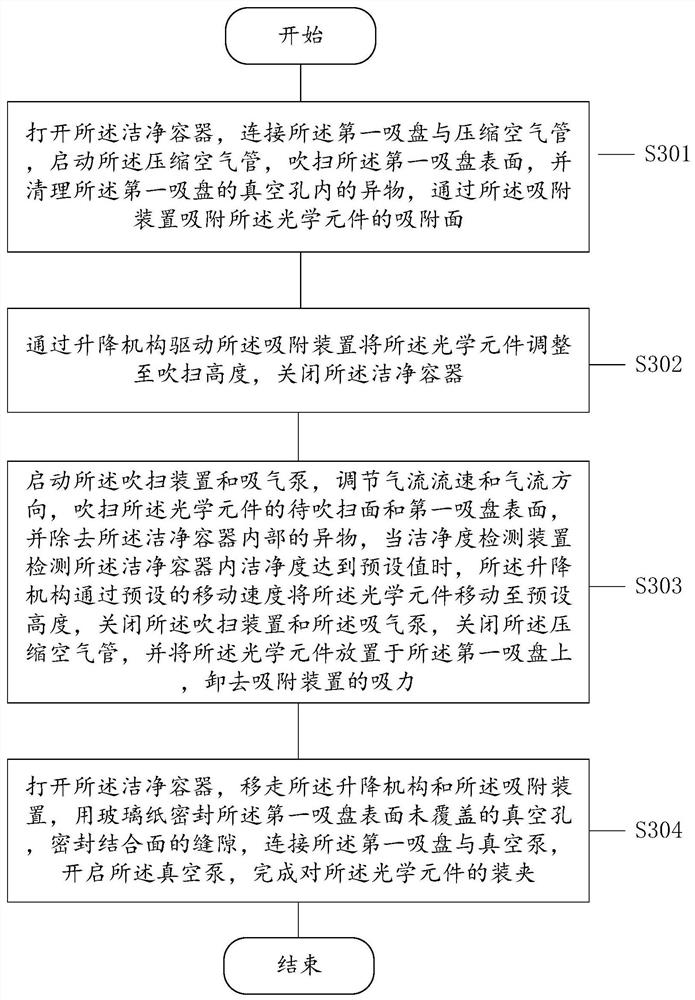

[0043] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

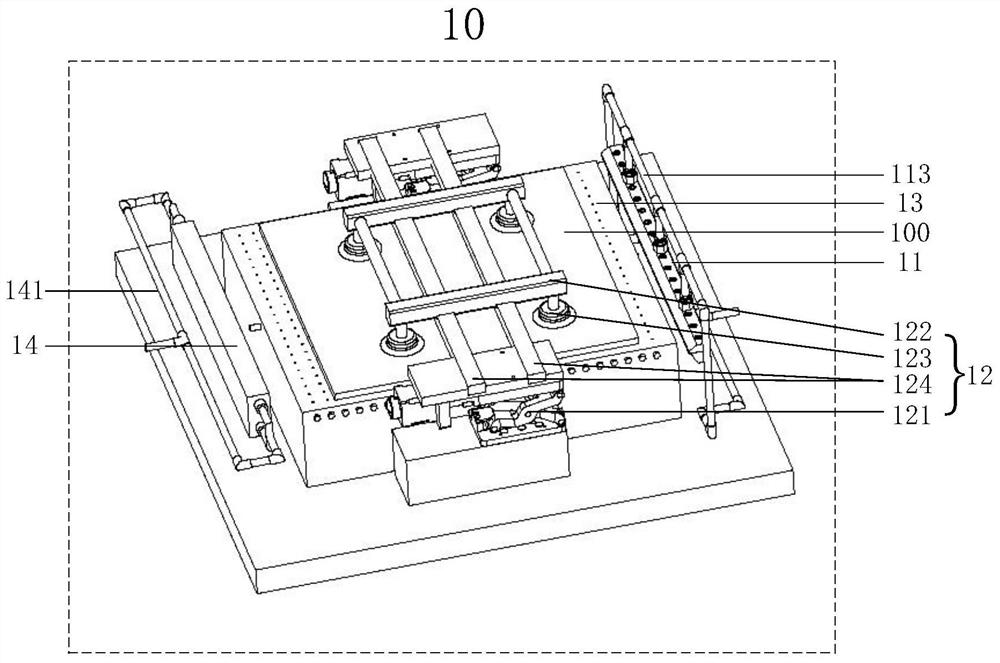

[0044] figure 1 For the structural diagram of an optical element defect suppression device provided in the embodiment of this application, please refer to figure 1 , the suppression device 10 of the optical element defect may include:

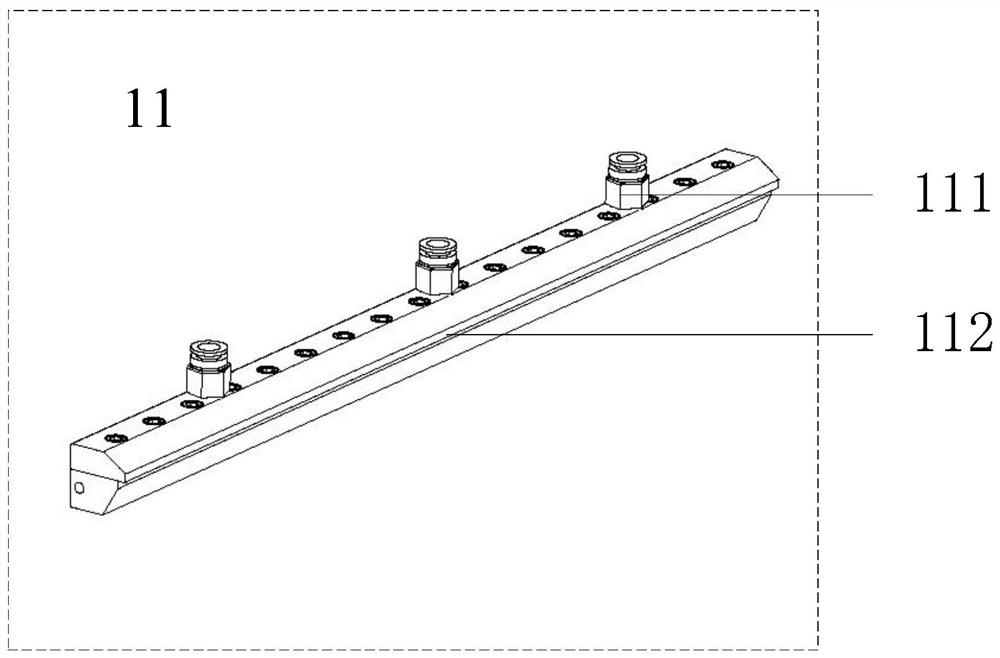

[0045]Purging device 11, adsorption device 12, first suction cup 13 and clean container, described adsorption device 12, described purging device 11 and described first suction cup 13 are all installed in the described clean container; The air outlet of 11 faces the surface to be cleaned of the optical element 100; the adsorption device 12 includes a suction lifting mechanism 121 and an adsorption mechanism, and the suction lifting mechanism 121 is connected with the adsorption mechanism; the first suction cup 13 is arranged on On the base of the clean container, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com