A collaborative control method for a stewart platform

A collaborative control and platform technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of uncoordinated and difficult control of the telescopic length of electric cylinders, and achieve high-performance pose control requirements and improve control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

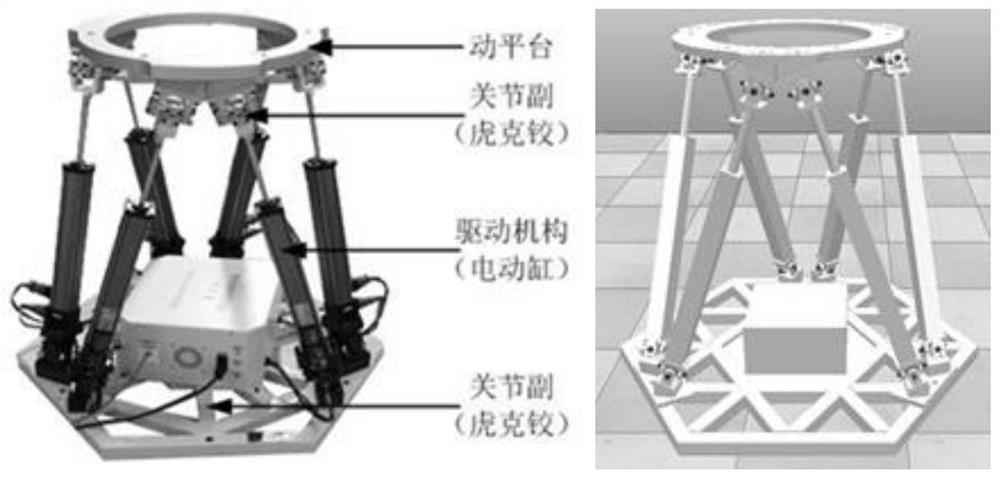

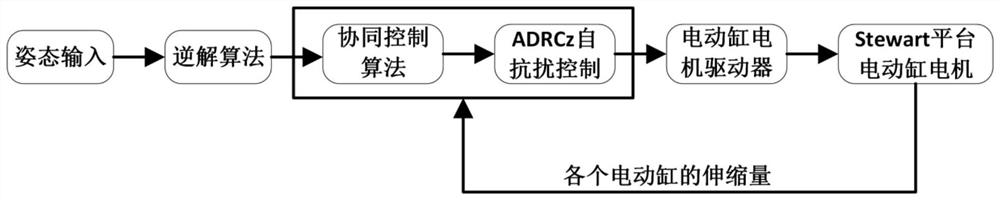

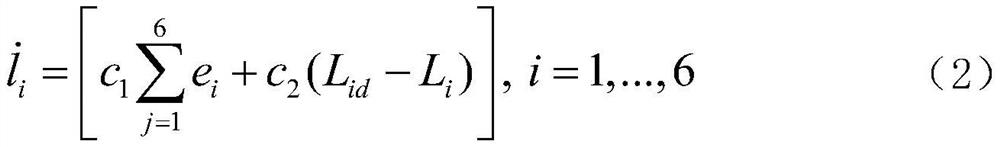

[0042] In order to clearly describe the motion of Stewart, the kinematic modeling of the platform is first carried out.

[0043] Such as figure 1 As shown in , put all the electric cylinders to the neutral position, that is, extend half of the full-scale length as the initial reference pose of the Stewart platform. Such as figure 2 As shown in , the line connecting the two adjacent endpoints farther away from the base platform is parallel to the viewing angle, and starting from the left point, mark the hinge point B clockwise. 1 , B 2 , B 3 , B 4 , B 5 , B 6, and the electric cylinders connected to it are respectively marked as P at the hinge point of the moving platform 1 ,P 2 ,P 3 ,P 4 ,P 5 ,P 6 , the hinge points of the base platform and the moving platform are denoted as B i ,P i .

[0044] Establish the base platform coordinate system O B -X B Y B Z B and moving platform coordinate system O P -X P Y P Z P , where the origin of the base coordinate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com