Blind hole machining rotary cutting system and blind hole machining method

A processing method, blind hole technology, applied in metal processing equipment, manufacturing tools, welding/welding/cutting items, etc., can solve the problems of high cost of rotary cutting equipment, large blind hole taper, etc., to improve quality and avoid blind holes Taper, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

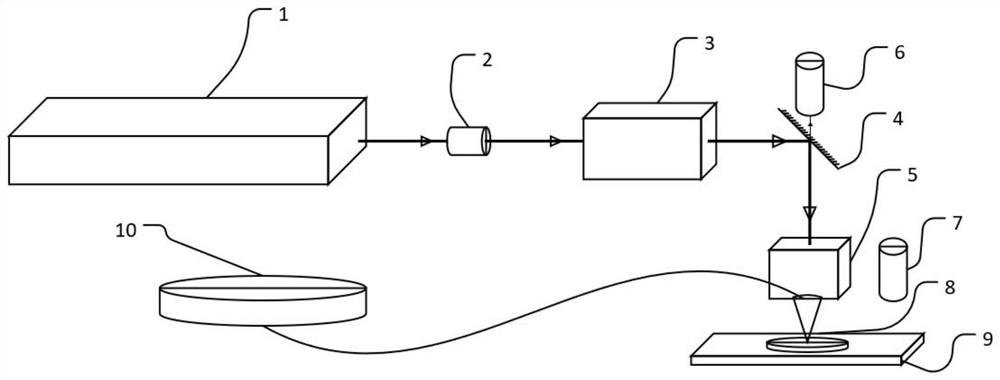

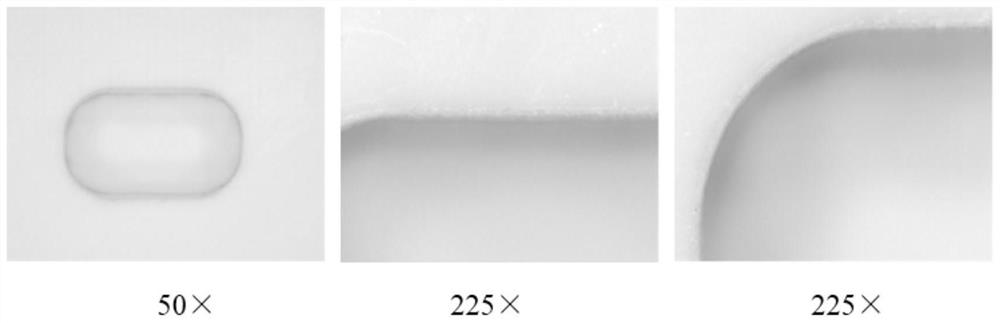

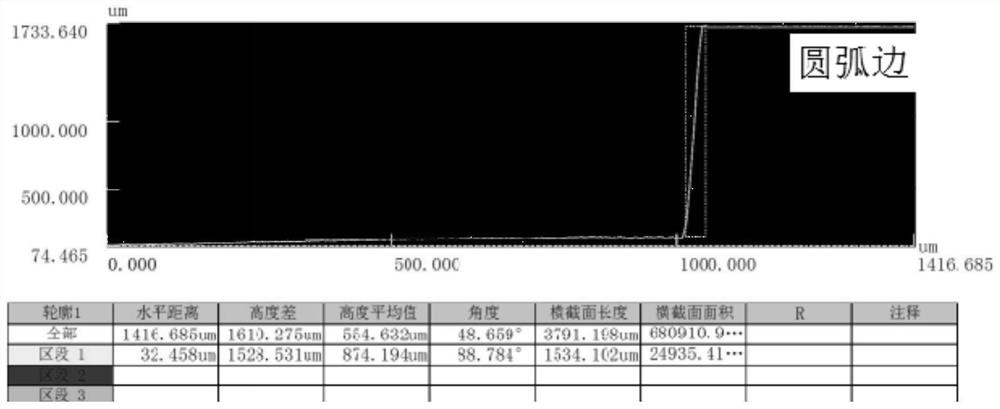

[0055] Please refer to figure 1 , this embodiment provides a blind hole processing rotary cutting system, figure 1 Schematic diagram of the structure of the rotary cutting system for blind hole processing provided by the embodiment of the present invention; figure 2 The magnified effect diagram of the blind hole processed by the blind hole processing rotary cutting system provided for the embodiment of the present invention, from left to right is the blind hole effect diagram enlarged by 50 times, the blind hole edge effect diagram enlarged by 225 times, and the blind hole edge effect diagram enlarged by 225 times Blind hole corner renderings. Figure 3-Figure 5 The 3D microscope measurement results of the blind holes processed by the blind hole processing rotary cutting system provided for the embodiments of the present invention.

[0056] The blind hole processing rotary cutting system provided in this embodiment is an ultra-fast laser drilling processing equipment, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com