Teaching method of industrial robot

A technology of industrial robots and teaching methods, which is applied in the field of robots, can solve time-consuming problems, and achieve the effects of simple and convenient operation methods, quick learning and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

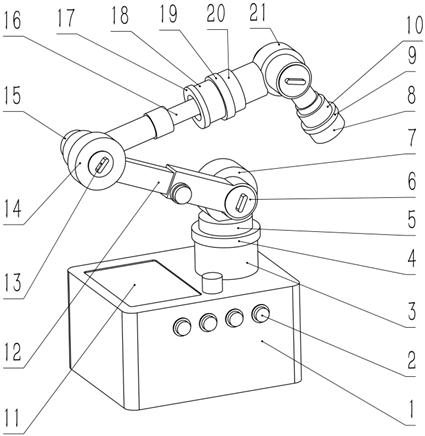

Embodiment 1

[0023] A teaching method for an industrial robot. The length of each mechanical arm of the industrial robot is scaled year-on-year to design an unpowered mechanical arm teaching pendant with damping adjustment. Angle sensors and damping are arranged at each joint of the unpowered mechanical arm teaching pendant. Adjust the position of each arm of the teaching pendant freely by both hands, thereby driving the angle data given by the angle sensors of each joint, and driving the industrial robot to flexibly reach the desired position or trajectory according to the operator's intention, through damping adjustment Limit the movement speed or switch of the joint, so as to control the joint linkage of the part to be driven more freely, and quickly realize the teaching operation of the industrial robot.

[0024] Through the method disclosed in this implementation example, the position of each arm of the unpowered manipulator teaching pendant is manually moved freely with both hands, th...

Embodiment 2

[0027] The unpowered mechanical arm teaching pendant includes a control unit, several angle sensors, dampers and mechanical arms, wherein several mechanical arms are connected to form an industrial robot mechanical arm structure, and several dampers are respectively installed at the joints of the rotary joints of the mechanical arms. The angle sensor is correspondingly installed on the damper, and the control unit is connected with the angle sensor.

[0028] Preferably, a damping adjuster is installed on the damper.

[0029] Preferably, the mechanical arm is configured as a telescopic structural arm, so as to increase compatibility with the length of mechanical arms produced by different manufacturers.

[0030] Preferably, the angle electronic fine-tuning is installed at each joint nearby, and the precise motion of the mechanical arm of the industrial robot can be precisely controlled through the fine-tuning at the joints.

[0031] As a specific design, the angle electronic f...

Embodiment 3

[0033] As an extension of Embodiment 1, the unpowered manipulator-type teaching pendant is used in conjunction with the panel-type teaching pendant as an extension component of the panel-type teaching pendant.

[0034] The unpowered manipulator teaching pendant can be used alone, and can also be used in conjunction with the panel teaching pendant as an expansion part of the panel teaching pendant. Angle sensors, dampers and damping adjustments are installed at each joint of the unpowered manipulator-type teach pendant, and are used together with the panel-type teach pendant as an expansion part of the panel-type teach pendant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com