Centering deviation rectifying structure using swing triangular plate

A triangular plate and swing shaft technology, which is applied in the directions of transportation and packaging, liquid bottling, and packaging item types, etc., can solve problems such as poor alignment accuracy, misalignment of packaging film folded in half, and less vertical seal connection, so as to ensure production efficiency , Improve the effect of half-folding and improve the effect of half-folding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

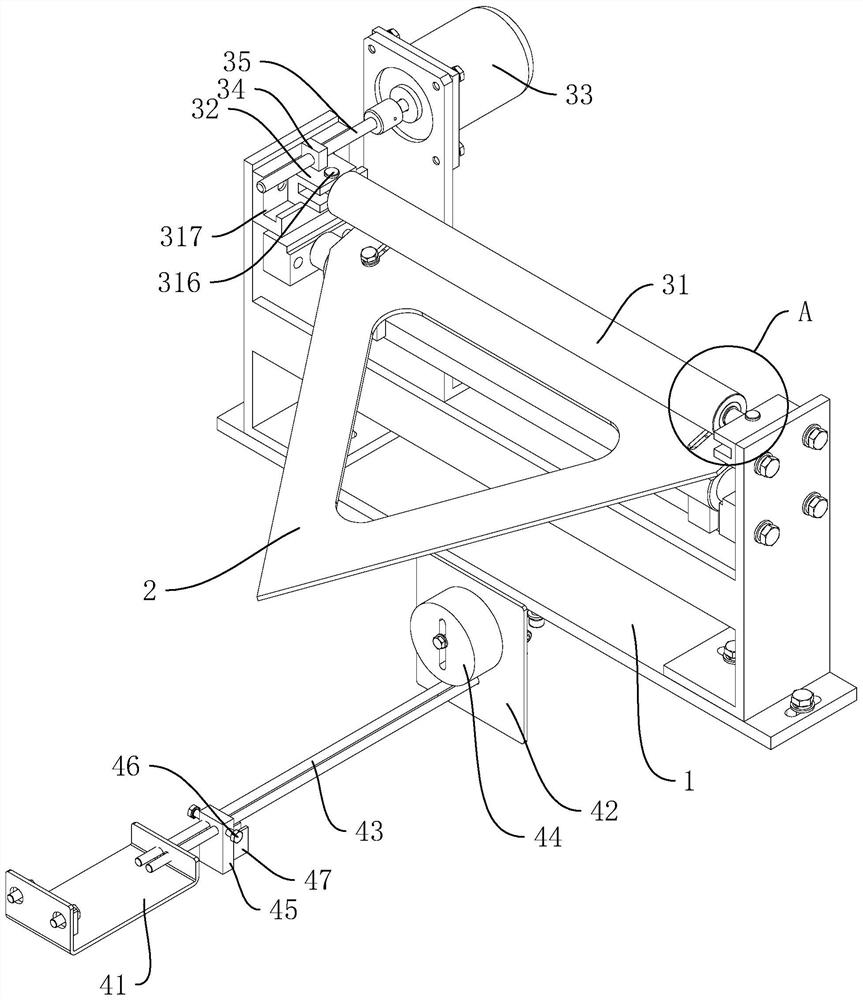

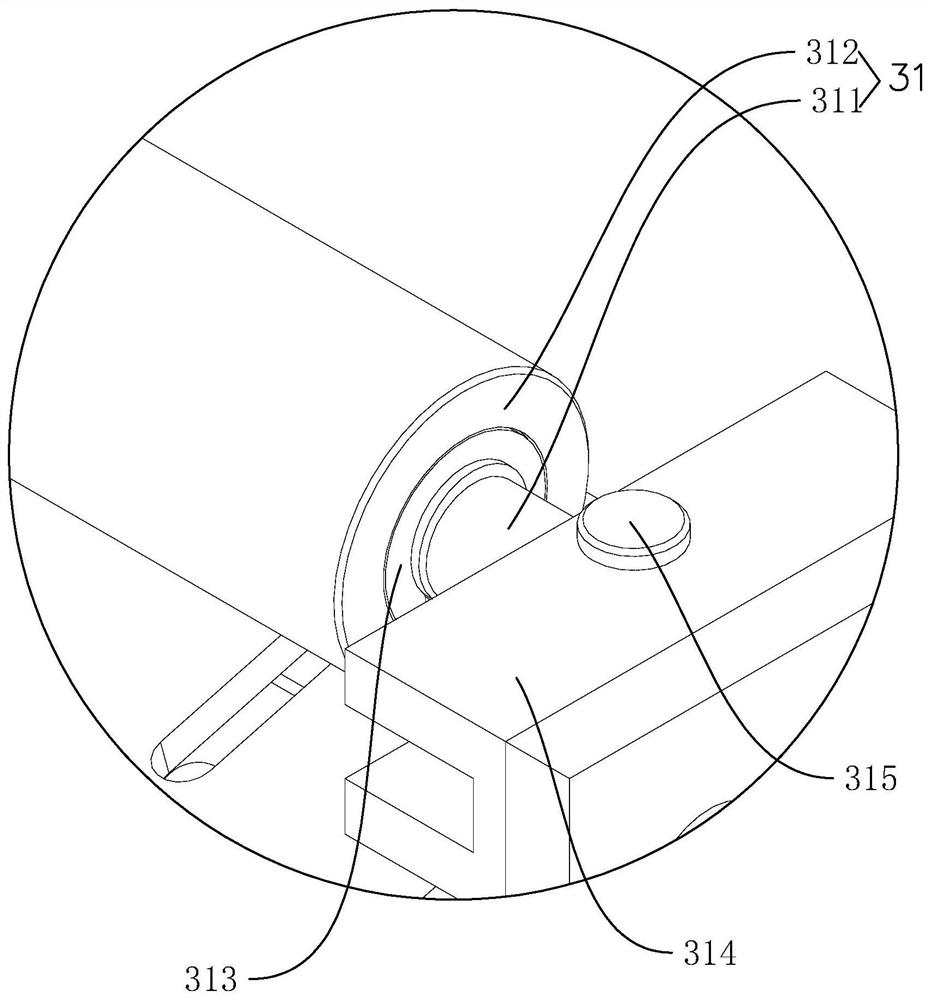

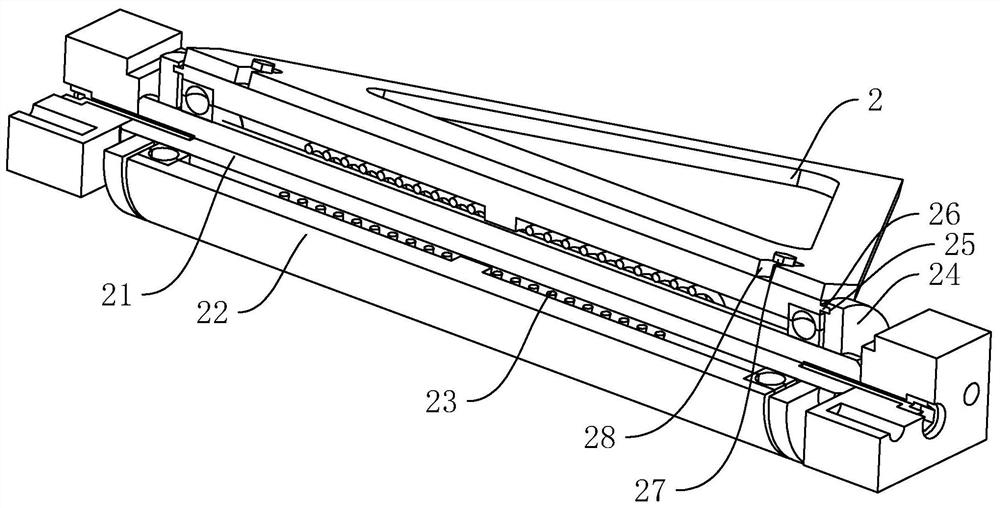

[0030] Use the centering and deviation correction structure of the swing triangle, such as figure 1 As shown, it includes a mounting seat 1 located directly above the central filling pipe, an isosceles triangular plate 2 arranged on the mounting seat 1, a pendulum roller assembly located above the isosceles triangular plate 2, and a clamping assembly located below the isosceles triangular plate 2; The pendulum roller assembly includes a pendulum roller 31 horizontally hinged to the mounting base 1 at one end, a connecting block 32 arranged at the other end of the pendulum roller 31, and a servo motor 33 for pushing the connecting block 32. The connecting block 32 is processed with a threaded sleeve 34, The output shaft of the servo motor 33 is fixed with a screw rod 35 threadedly fitted with a threaded sleeve 34 .

[0031]When this application is working nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com