Shuttle vehicle with steering mechanism and used for automatic stereoscopic warehouse

A three-dimensional warehouse and steering mechanism technology, which is applied in the directions of transportation, packaging, storage devices, etc., can solve the problems such as the inability to effectively realize rapid steering and rail change, the inability of the shuttle to be effectively applied, and the reduction of the use efficiency of the shuttle. The efficiency of design and construction, the effect of improving practicality, and improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

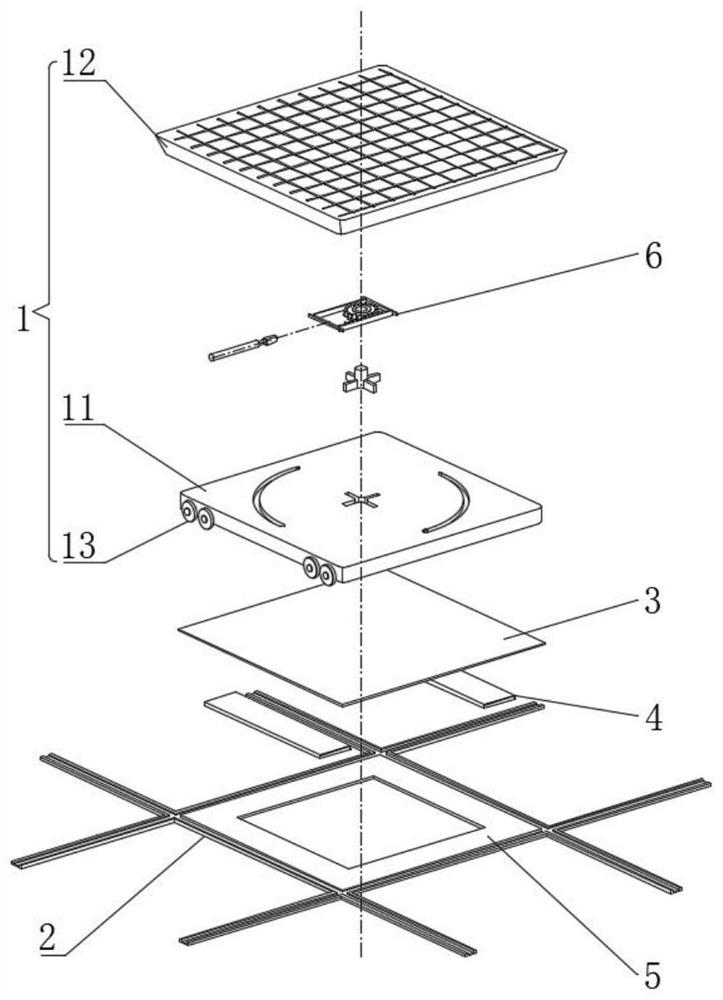

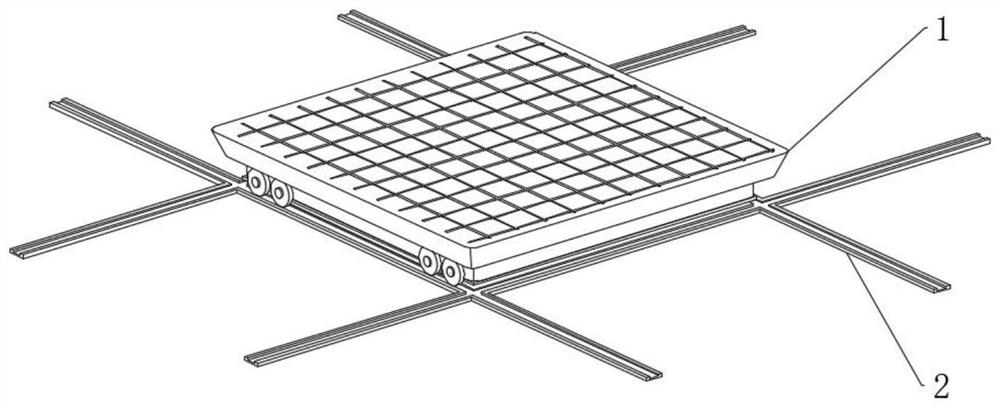

[0050] see Figure 1-9 , a shuttle car for an automated three-dimensional warehouse with a steering mechanism, comprising a car body 1 and a track 2, the car body 1 is located at the upper end of the track 2, the car body 1 includes a car base 11, and the upper end of the car base 11 is connected to a roof plate 12, The lower end of the vehicle base 11 is connected with a wheel mechanism 13, and the lower end of the vehicle base 11 is fixedly connected with a magnetic isolation plate 3 positioned at the inner side of the wheel mechanism 13. The lower end of the magnetic isolation plate 3 is fixedly connected with a pair of electromagnetic systems 4. The upper end of the track 2 is provided with a wheel mechanism. 13 matching track grooves, the joints of the two vertical tracks 2 are fixedly connected with the repelling electromagnetic coil 5 matching the electromagnetic system 4, and the lower end of the roof panel 12 is connected with the steering assembly 6 matching the vehic...

Embodiment 2

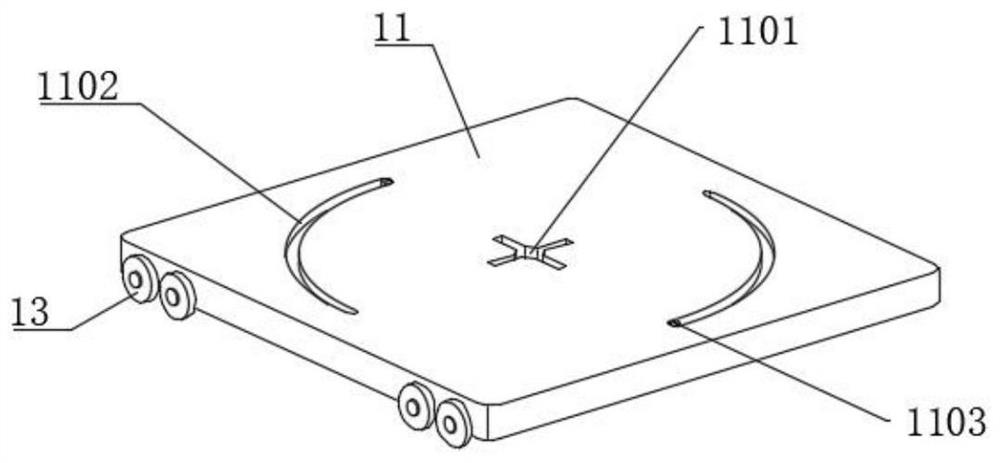

[0059] see Figure 1-9 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to image 3 A pair of arc-shaped grooves 1102 are provided on the upper end of the vehicle base 11, and a swivel sleeve 1103 is slidably connected in the arc-shaped grooves 1102, and the arc of the arc-shaped grooves 1102 is π / 2. Through the cooperation between the rotating sleeve 1103 and the arc-shaped groove 1102, it is convenient to limit the rotation angle of the car base 11, improve the precision of the rotation, facilitate the precise steering of the car body 1, and improve the matching accuracy of the car body 1 and the track 2.

[0060] see Figure 4 The lower end of the roof panel 12 is fixedly connected with a pair of limit rods 1203 matching th...

Embodiment 3

[0063] see Figure 1-9 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to Figure 9 , a kind of steering method with the shuttle car of automatic three-dimensional warehouse with steering mechanism, comprises the following steps:

[0064] S1. Control the car body 1 to move to the intersection of two vertical tracks 2;

[0065] S2. Make the electromagnetic system 4 and the repelling electromagnetic coil 5 energized at the same time to generate repelling magnetic force, so that the car body 1 is suspended on the upper end of the track 2;

[0066] S3. Start the steering assembly 6, drive the car base 11 to rotate 90° at the lower end of the roof plate 12, and the car base 11 drives the wheel mechanism 13 to rotate 90°;

[0067]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com