Belt conveyor

A technology of belt conveyor and transmission device, which is applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., and can solve the problem that the motor cannot be moved out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

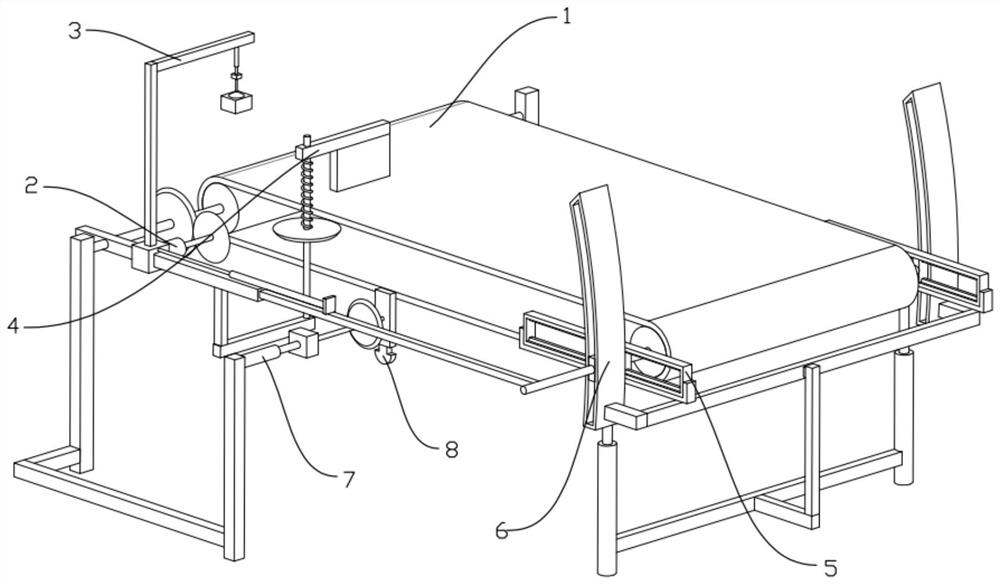

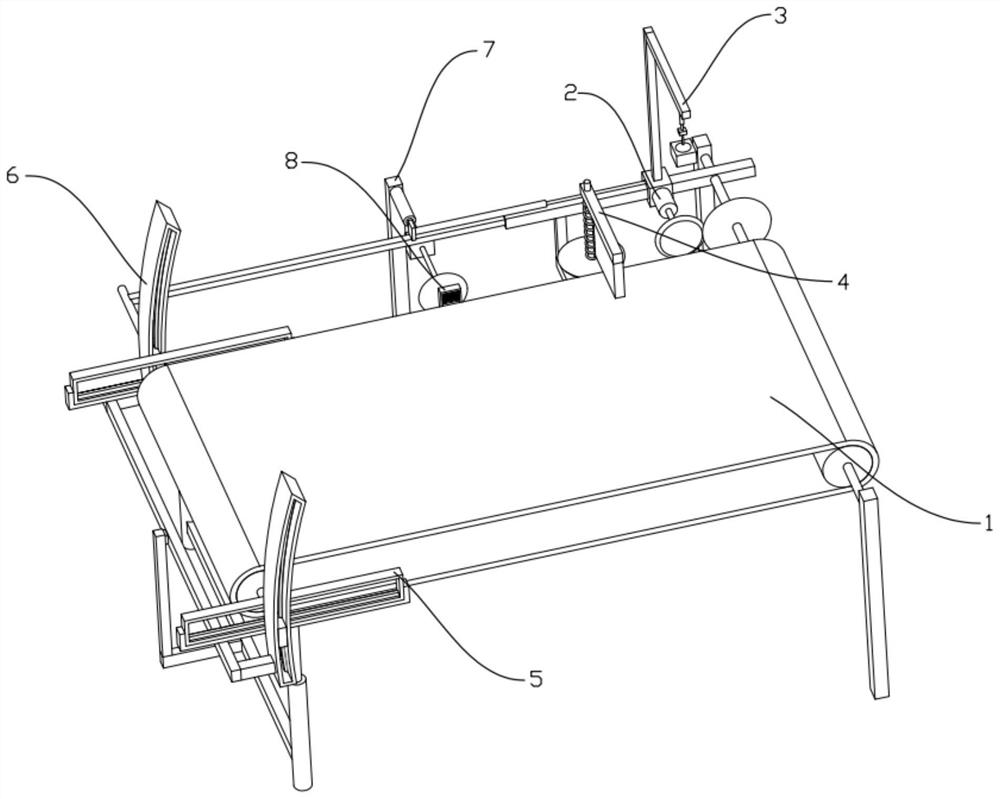

[0029] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10 illustrate this embodiment. The present invention relates to the field of industrial equipment, more specifically a belt conveyor, including a transmission device 1, a drive device 2, a trigger Slider mechanism 3, scraping mechanism 4, inclined support device 5, sliding device 6, matching device 7 and beating device 8, it is characterized in that: described driving device 2 is connected on trigger slider mechanism 3, trigger slider mechanism 3 is connected to the conveying device 1, the scraping mechanism 4 is connected to the conveying device 1, the inclined supporting device 5 is connected to the conveying device 1, the sliding device 6 is connected to the inclined supporting device 5, and the matching device 7 is connected to the conveying device 1, The beating device 8 is connected to the matching device 7, and the motor can be moved out when the conveyor belt is overloaded and the motor stops, and the excess...

specific Embodiment approach 2

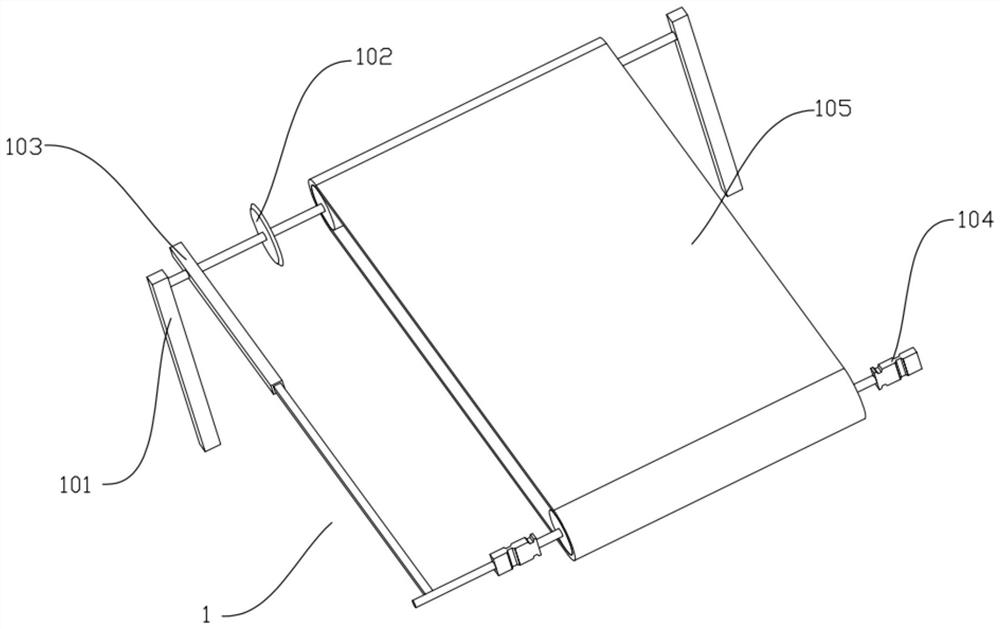

[0031] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The transmission device 1 includes a support column I101, a first gear 102, and a connecting rod 103 1. The multi-slide slider 104 and the conveyor belt 105, the first gear 102 is fixedly connected to the left end of the front side of the conveyor belt 105, the left and right ends of the front side of the conveyor belt 105 are respectively connected to the two supporting columns I101 in rotation, and the connecting rod 103 is fixedly connected to the conveyor belt 105 The left end of the front side, the left and right sides of the rear end of the conveyor belt 105 are respectively rotatably connected to two multi-slideway sliders 104, and the left side multi-slideway slider 104 is fixedly connected to the rear end of the connecting rod 103, and the materials to be transported are placed on the conveyor belt 105, the driving device...

specific Embodiment approach 3

[0033] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The drive device 2 includes a motor 201 and a second gear 202, and the second gear 202 Fixedly connected to the output shaft of the motor 201, the second gear 202 meshes with the first gear 102, the motor 201 rotates to drive the second gear 202 to rotate, the second gear 202 rotates to drive the first gear 102 to rotate, and the first gear 102 rotates the conveyor belt The conveyor belt 105 rotates, and the conveyor belt 105 rotates to drive the materials placed on the conveyor belt 105 to be transported.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com