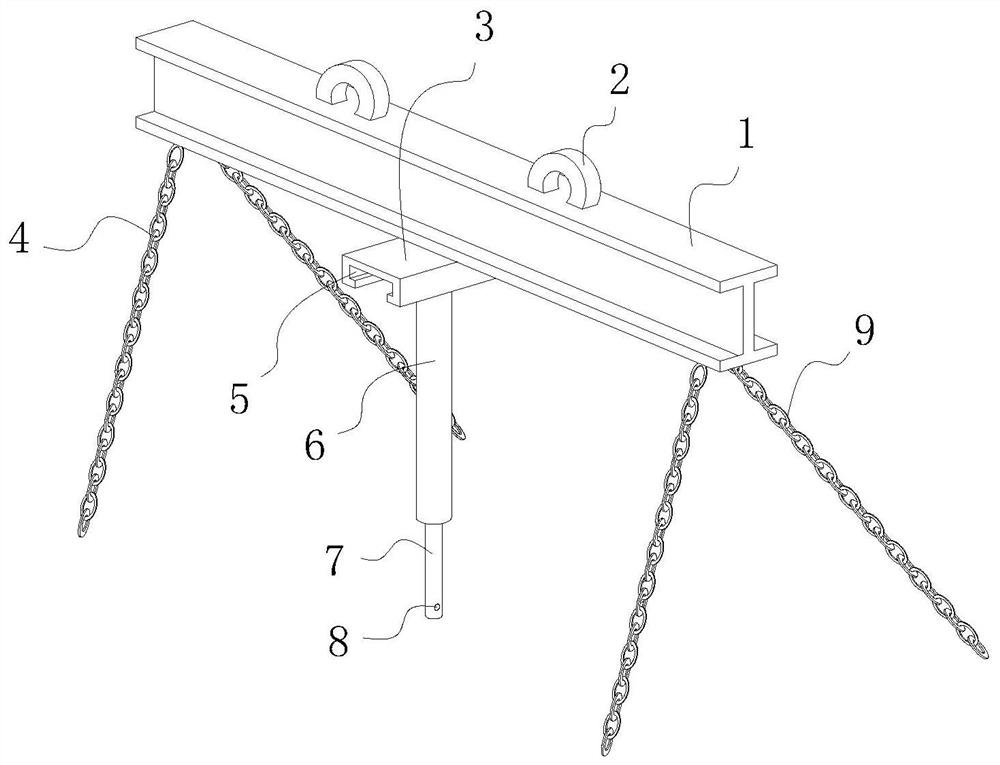

Stable hoisting system for fabricated integral building composite floor slab

A kind of superimposed floor, integral technology, applied in the field of superimposed floor hoisting, can solve the problems that affect the stability of hoisting, superimposed floors are easy to shake, etc., and achieve the effect of improving stability, loosening dust and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

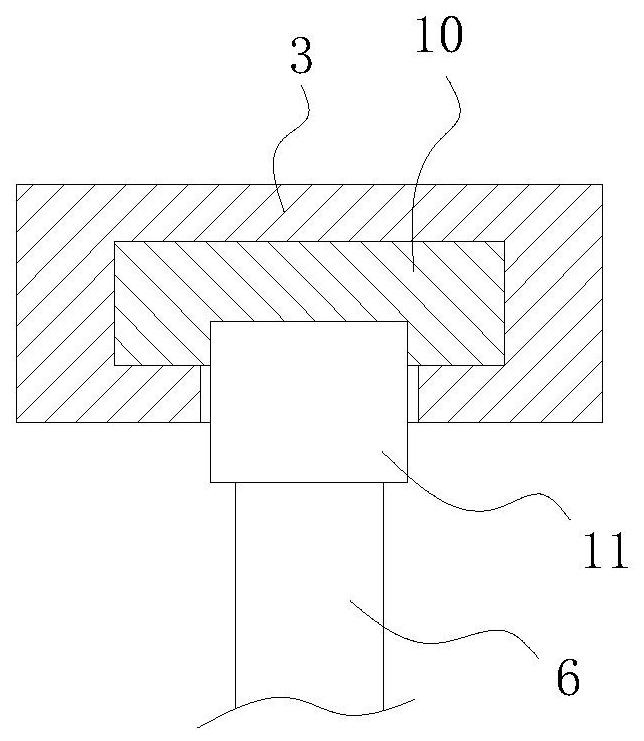

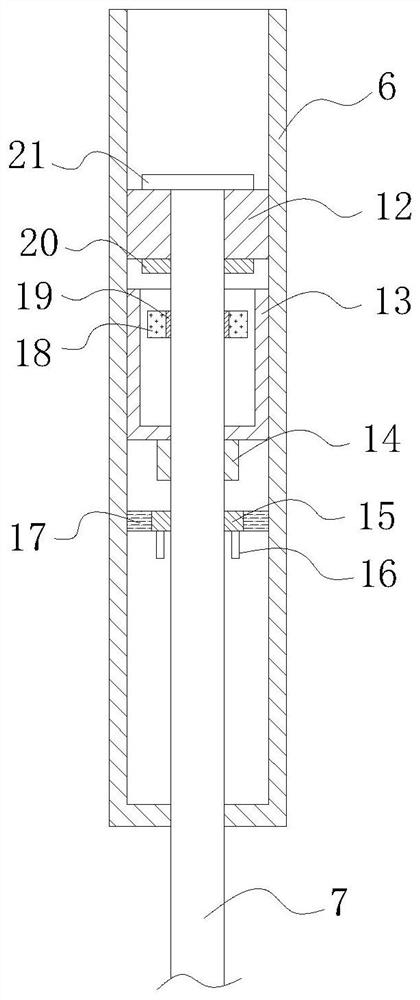

[0046] Specific implementation method: insert the limit plate 10 in the T-shaped groove 5 on the support plate 3 to realize the insertion of the hollow tube 6 and the support plate 3, that is, to complete the connection between the hollow tube 6 and the beam 1, and connect the first iron chain After 4 and the second iron chain 9 are connected on the pre-embedded steel bar 32, pull out the drawer rod 7 from the hollow pipe 6, and use a rope to connect the drawer rod 7 with the pre-embedded steel bar 32, and then connect the drawer rod 7 to the pre-embedded steel bar 32. The tie rods 7 jointly play the role of connecting the laminated floor 31 and the beam 1, which is convenient for maintaining the stability of the relative position of the laminated floor 31 and the beam 1, and avoiding relatively large shaking of the laminated floor 31 relative to the beam 1 during the hoisting process. Improve the stability of the hoisting of the laminated floor 31, adjust the position of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com