Marine floating garbage collection device

A technology of garbage collection and equipment, applied in water conservancy projects, open water surface cleaning, construction, etc., can solve the problems of time-consuming and labor-intensive efficiency, easy fatigue in salvage work, and unfavorable large-scale use, and achieve the effect of facilitating garbage falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

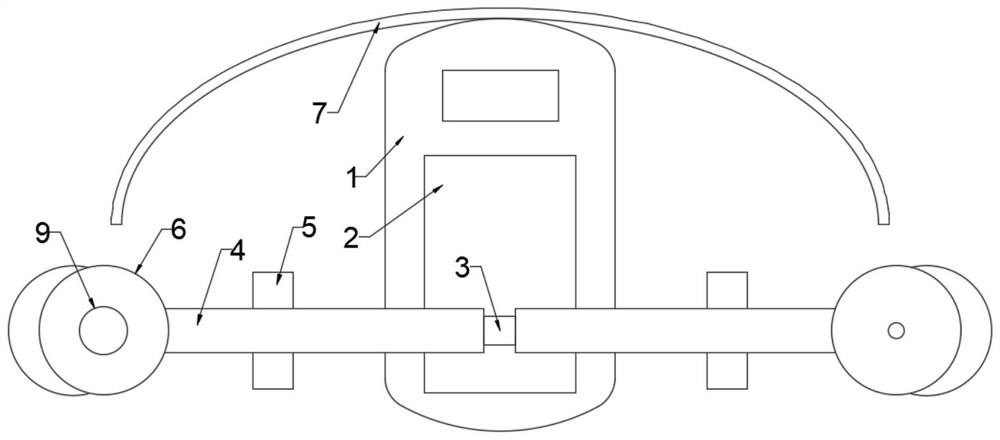

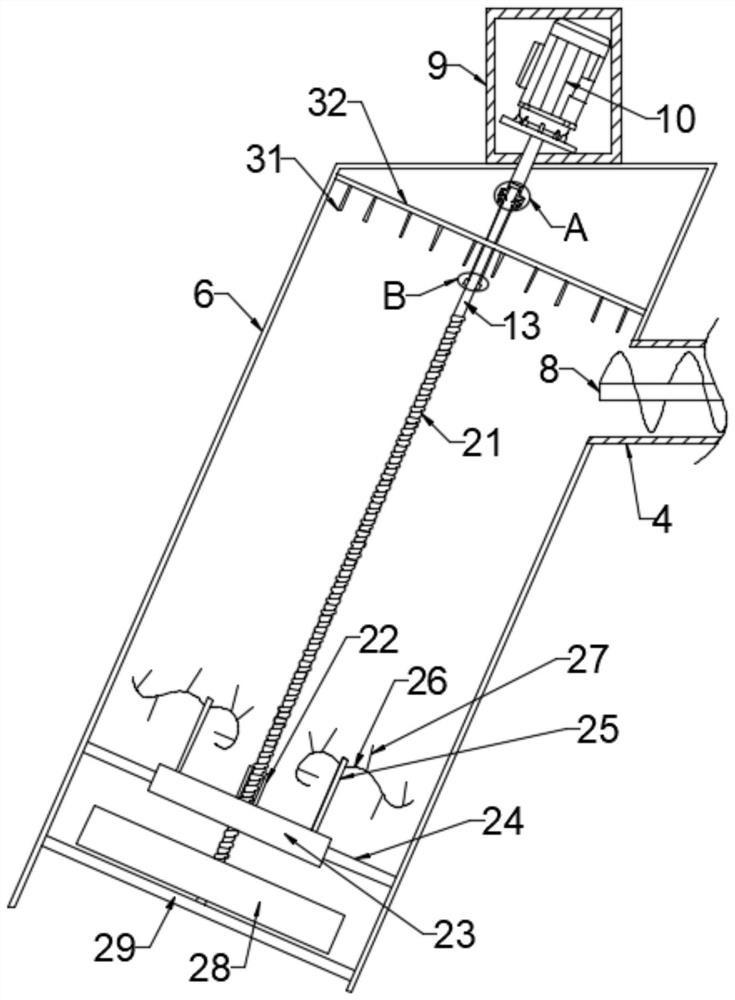

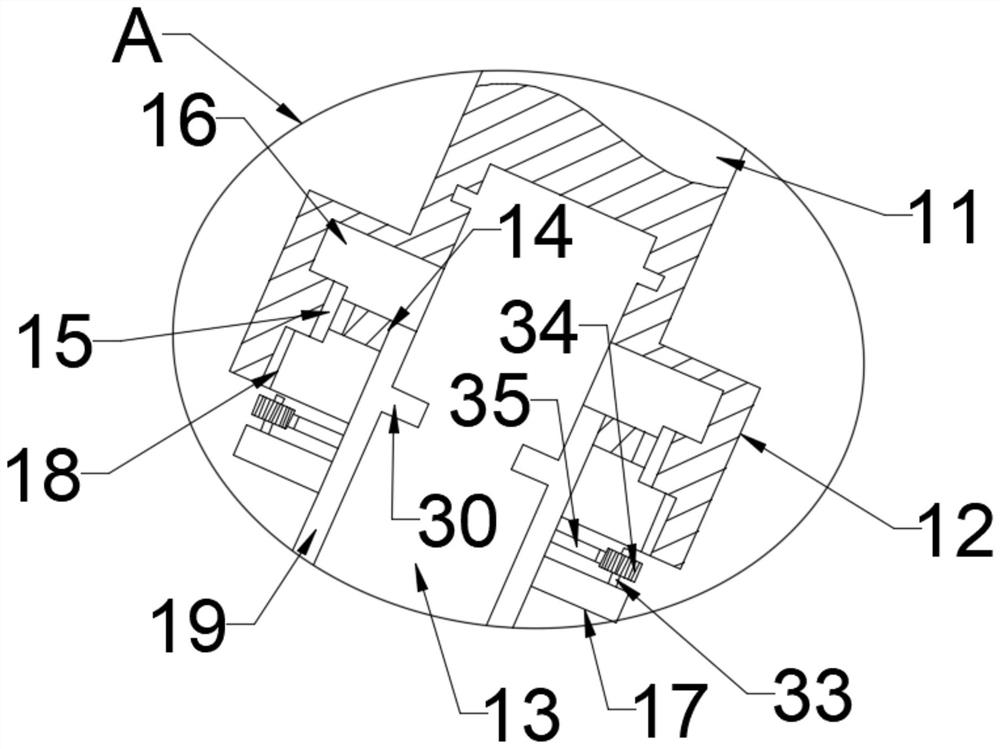

[0028] see Figure 1-5 , a marine floating garbage collection equipment, comprising a hull 1, the front end of the hull 1 is fixedly connected with an arc-shaped baffle 7, the hull 1 is provided with a garbage tank 2, and the upper end of the garbage tank 2 is provided with a first drive box 3, the second The two sides of a drive box 3 are provided with symmetrically distributed transport mechanisms, each of which is connected to a catch box 6, and the shell of the catch box 6 immersed in water is provided with evenly distributed hollow grooves to facilitate the entry of garbage into the catch box 6 Inside, the axis of the inner cavity of the fishing box 6 is provided with a driving rod, and the driving rod is driven to rotate through the second driving box 9 arranged on the fishing box 6. The lower end of the driving rod is provided with a fishing mechanism. When the hull 1 starts At this time, the garbage in front of the arc-shaped baffle 7 floats along the arc-shaped baffle...

Embodiment 2

[0038] This embodiment is expanded on the basis of Embodiment 1. The inner wall of the upper end of the fishing box 6 is fixedly connected with a blade mounting plate 32, and the blade mounting plate 32 is provided with a through hole for the third drive shaft 13 to pass through. 32 lower ends are fixedly connected with evenly distributed cutting blades 31, and the rubbish entangled on the fishing rod 26 can be cut by the cutting blades 31, making it easier to come off and leave the fishing rod 26 to be dropped in the auger box 4.

[0039] To sum up, when the hull 1 starts, the garbage in front of the arc-shaped baffle 7 floats along the arc-shaped baffle 7 to both sides, just at the catch box 6, and the servo motor 10 drives the first drive shaft 11 to rotate , the first drive shaft 11 drives the second drive shaft 12 to drive the third drive shaft 13 to rotate, the third drive shaft 13 drives the screw 21 to rotate, the screw 21 drives the stirring plate 28 to rotate, the sti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap