Novel assembly type steel structure adjustable force transmission beam

A prefabricated, steel structure technology, used in building components, building types, building structures, etc., can solve the problems of cumbersome assembly, large prefabricated beams, and difficult positioning of prefabricated beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

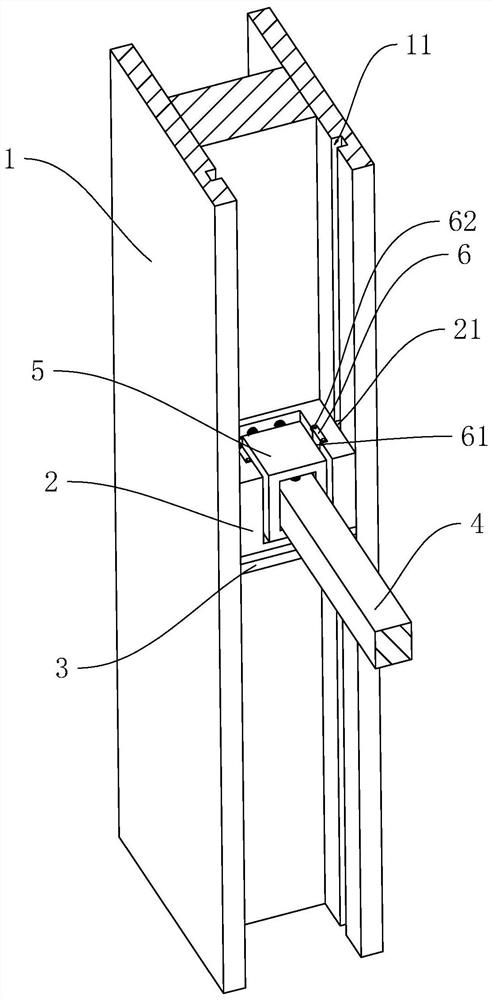

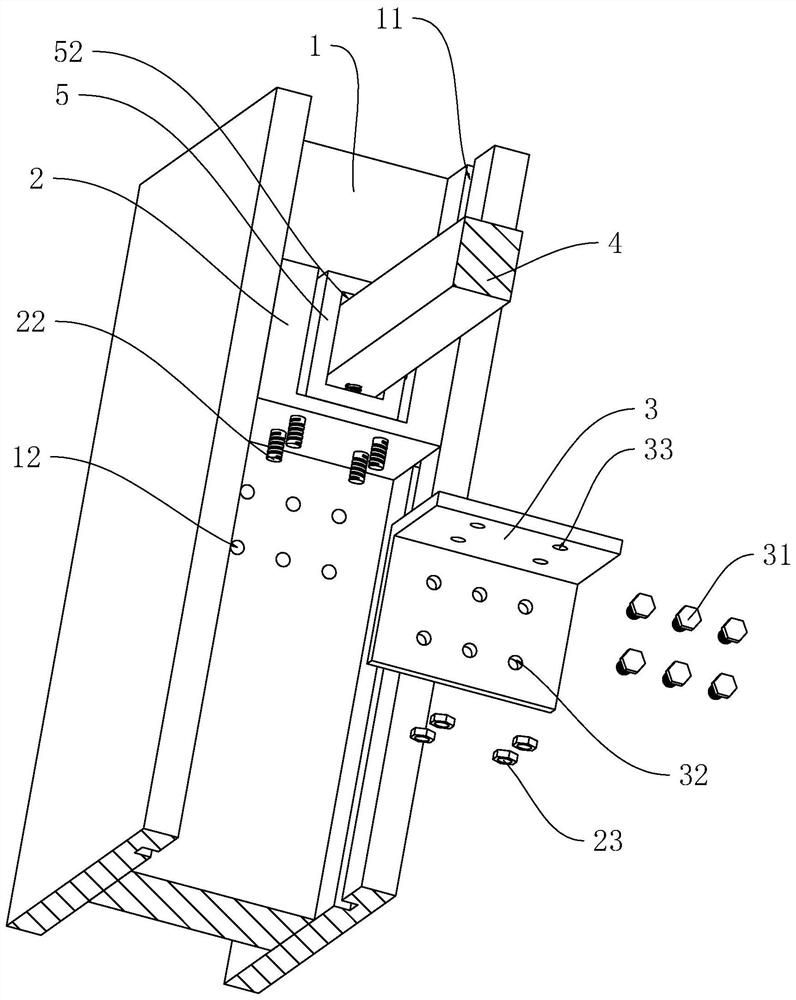

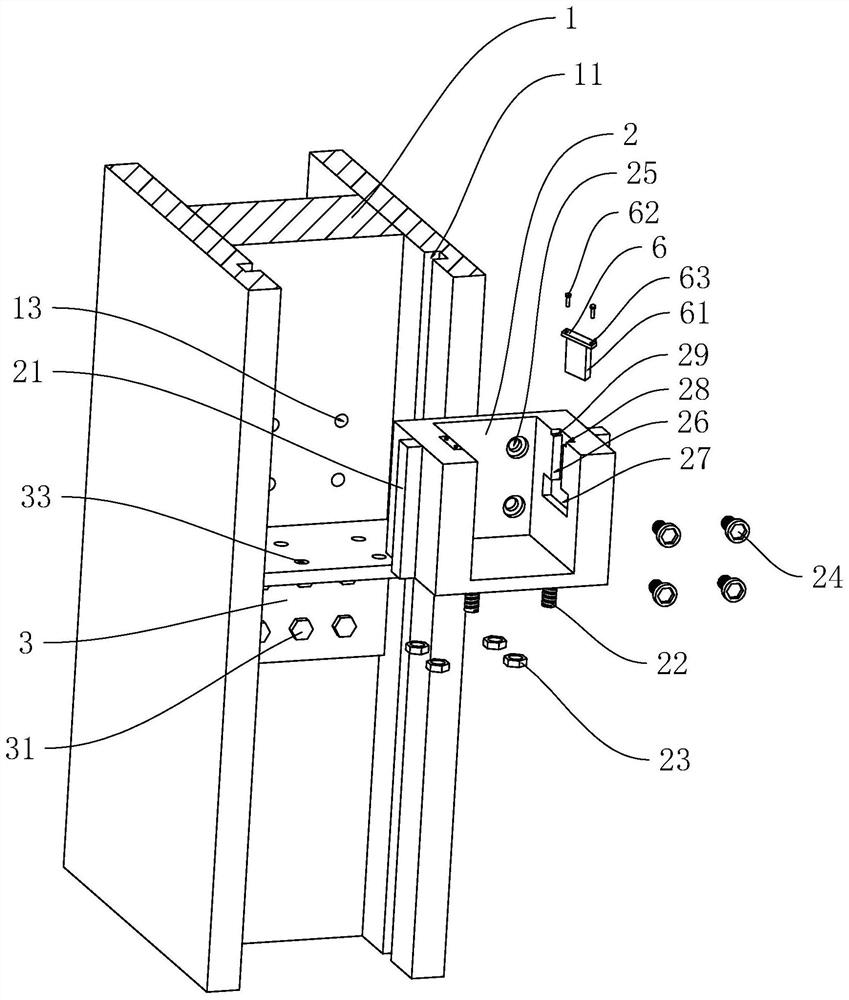

[0037] The following is attached Figure 1-5 The application is described in further detail.

[0038] The embodiment of the present application discloses a novel assembled steel structure adjustable force transmission beam. refer to figure 1 , the new type of assembled steel structure adjustable force transmission beam includes an I-shaped steel column 1, the I-shaped steel column 1 is firmly installed on the foundation of the construction ground, and a mounting bracket is slidably connected to the notch of the I-shaped steel column 1 2. There is a sliding piece between the mounting bracket 2 and the I-shaped steel column 1. The sliding piece can not only facilitate the positioning of the mounting bracket 2, but also allow the mounting bracket 2 to move along the length of the I-shaped steel column 1. Slide the notch so that the mounting bracket 2 can be quickly installed.

[0039] Specifically, in this embodiment, the slider includes a slider 21, the slider 21 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com