Waterproof jacking pipe

A waterproof and pipe jacking technology, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of poor waterproof effect of the pipe body, damage to sockets and sockets, and affect the connection of sockets and sockets Effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

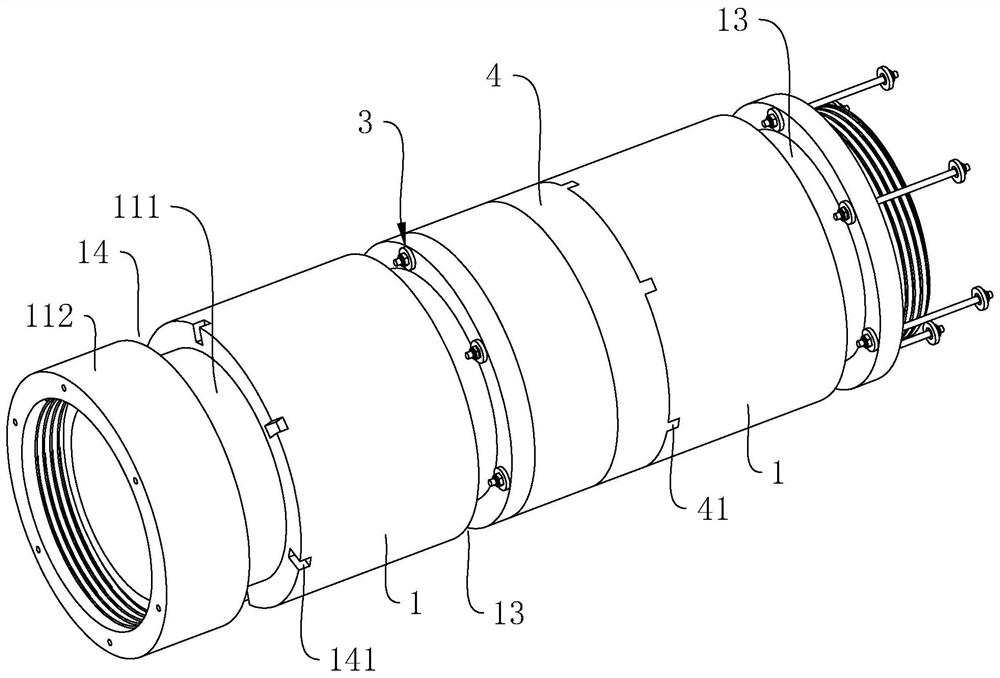

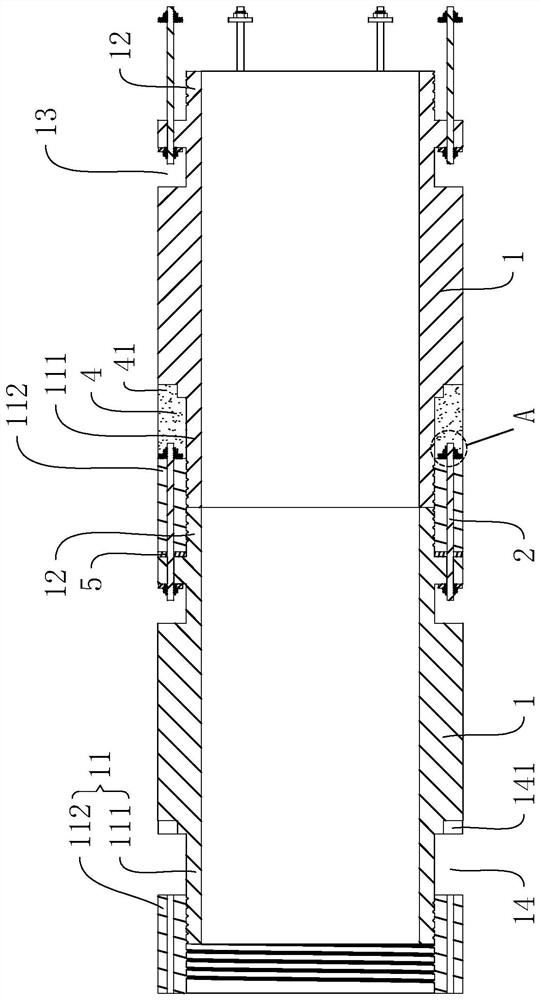

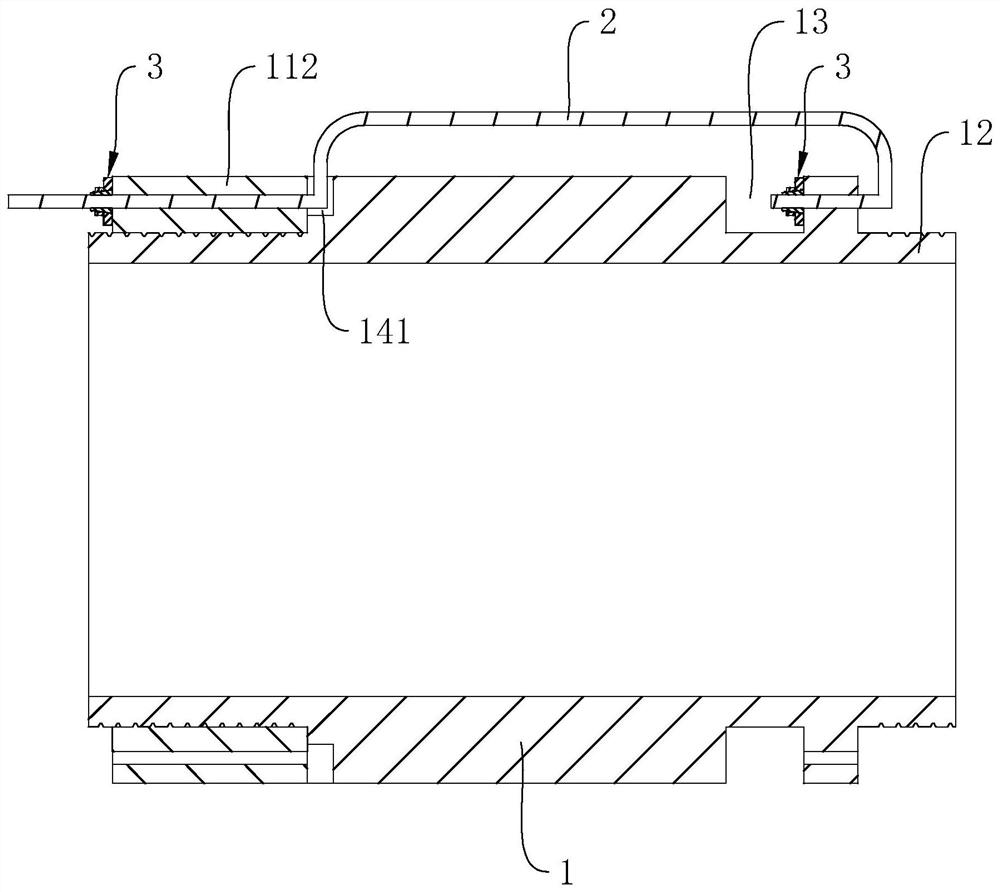

[0031] The following is attached Figure 1-4 The application is described in further detail.

[0032] The embodiment of the present application discloses a waterproof pipe jacking. refer to figure 1 , The waterproof type jacking pipe includes a unit pipe 1 and a prestressing device.

[0033] The unit pipes 1 are buried in the foundation through jacking equipment, and a plurality of unit pipes 1 are arranged along the axial direction of the unit pipes 1 . Two adjacent unit tubes 1 are inserted into each other, and the two ends of the unit tubes 1 are respectively provided with sockets 11 and sockets 12 for insertion. In this embodiment, the socket 12 of the unit tube 1 at the front matches the socket 11 of the unit tube 1 at the rear. The prestressing devices are arranged at one end of the unit tubes 1 close to each other, and there are multiple sets of prestressing devices along the circumference of the unit tubes 1 . In this embodiment, six sets are taken as an example fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com