Variable-frequency aeration device for rare earth tail water treatment

An aeration device and frequency conversion technology, applied in the field of frequency conversion aeration, can solve the problems of reduced processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

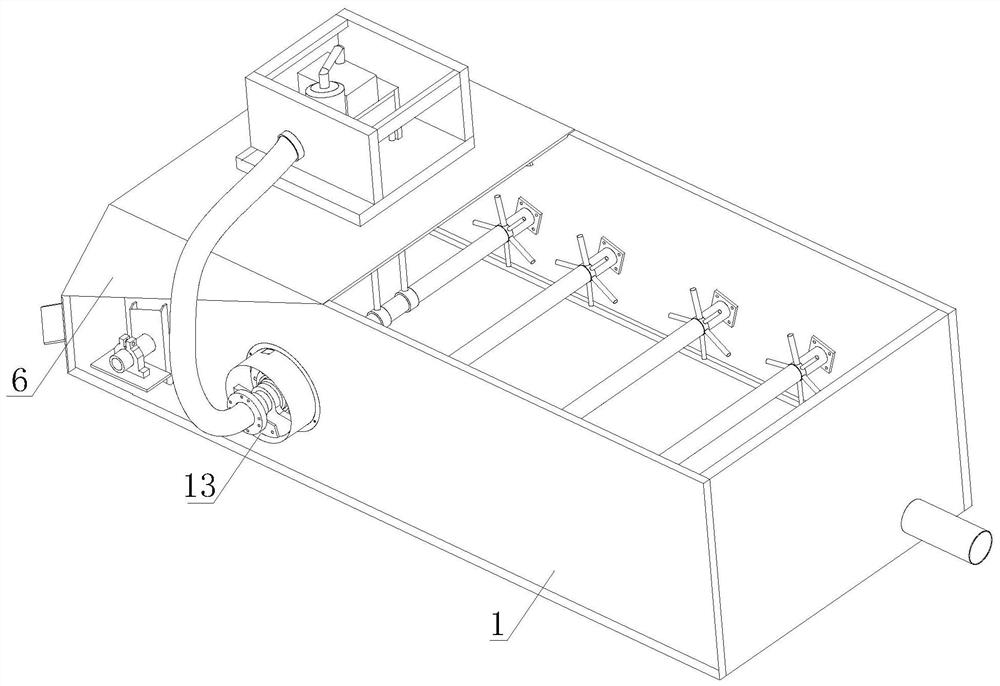

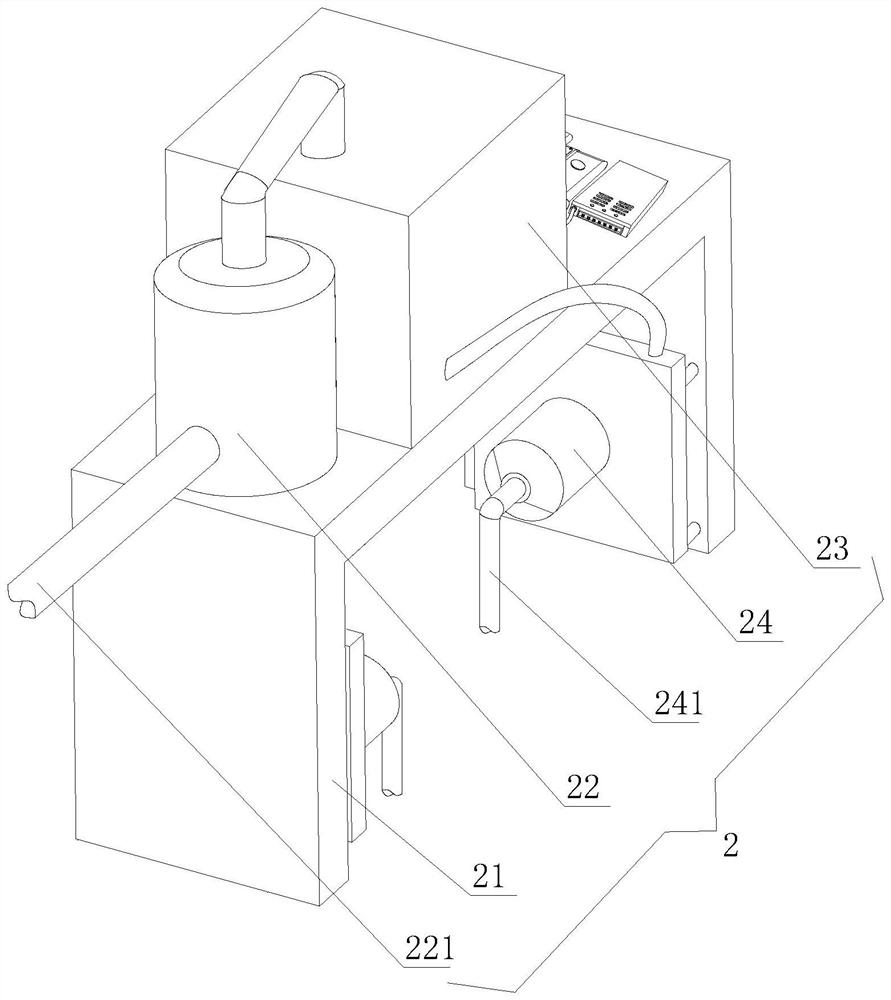

[0030] see figure 1 , a frequency conversion type aeration device for rare earth tail water treatment, comprising an aeration tank 1, a power mechanism 2, a stirring mechanism 3 and a frequency conversion mechanism 4, the top of the aeration tank 1 is covered with an upper cover 6, and the upper cover 6 aerates The top part of the tank 1 is covered, the power mechanism 2 and the frequency conversion mechanism 4 are connected and installed on the top surface of the upper cover 6, the power mechanism 2 and the frequency conversion mechanism 4 are arranged side by side, and the stirring mechanism 3 is distributed inside the aeration tank 1 , the stirring mechanism 3 works in the aeration tank 1 to stir the liquid in the aeration tank 1, and one end of the power mechanism 2 is set on the stirring mechanism 3, and a large amount of gas generated by the power mechanism 2 is discharged from the stirring mechanism 3, so as to realize stirring while stirring purpose of aeration.

[00...

Embodiment 2

[0040] see figure 1 , the top of the aeration tank 1 is covered with an upper cover 6, the upper cover 6 covers a part of the top of the aeration tank 1, the power mechanism 2 and the frequency conversion mechanism 4 are connected and installed on the top surface of the upper cover 6, the power mechanism 2 It is arranged side by side with the frequency conversion mechanism 4. The stirring mechanism 3 is distributed inside the aeration tank 1. The stirring mechanism 3 works in the aeration tank 1 to stir the liquid in the aeration tank 1. One end of the power mechanism 2 is set on the stirring mechanism 3. A large amount of gas generated by the power mechanism 2 is discharged from the stirring mechanism 3, thereby achieving the purpose of aeration while stirring.

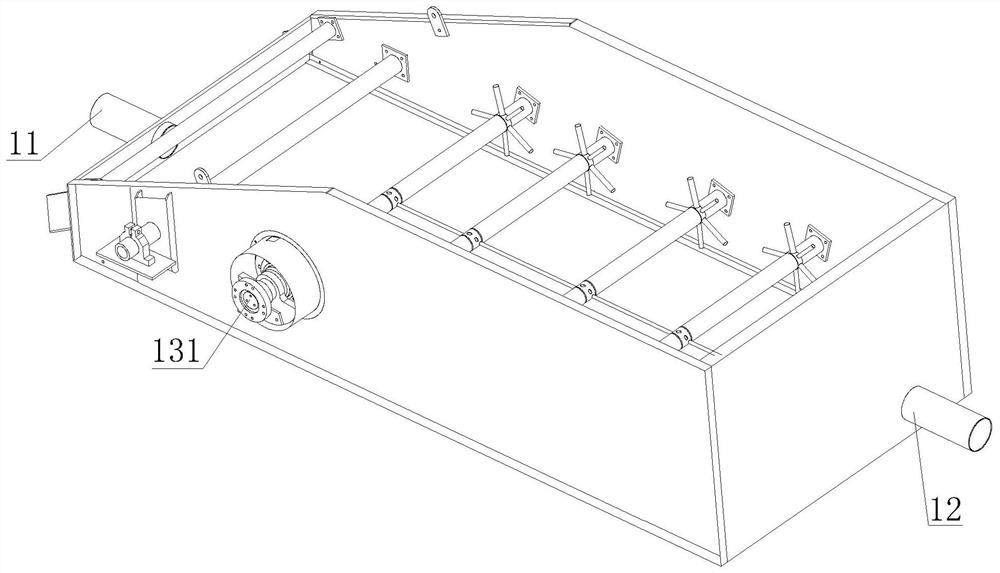

[0041] see figure 2 A liquid inlet pipe 11 and a liquid outlet pipe 12 are installed on both sides of the front and back of the aeration tank 1, and a water valve is installed on the liquid inlet pipe 11 and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com