Carbon dioxide transcritical direct cooling system for ice skating rink

A carbon dioxide, transcritical technology, used in refrigerators, ice making, leisure ice making, etc., can solve problems such as low efficiency and energy waste, and achieve improved stability of use, balanced cooling flow distribution, and consistent ice making efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

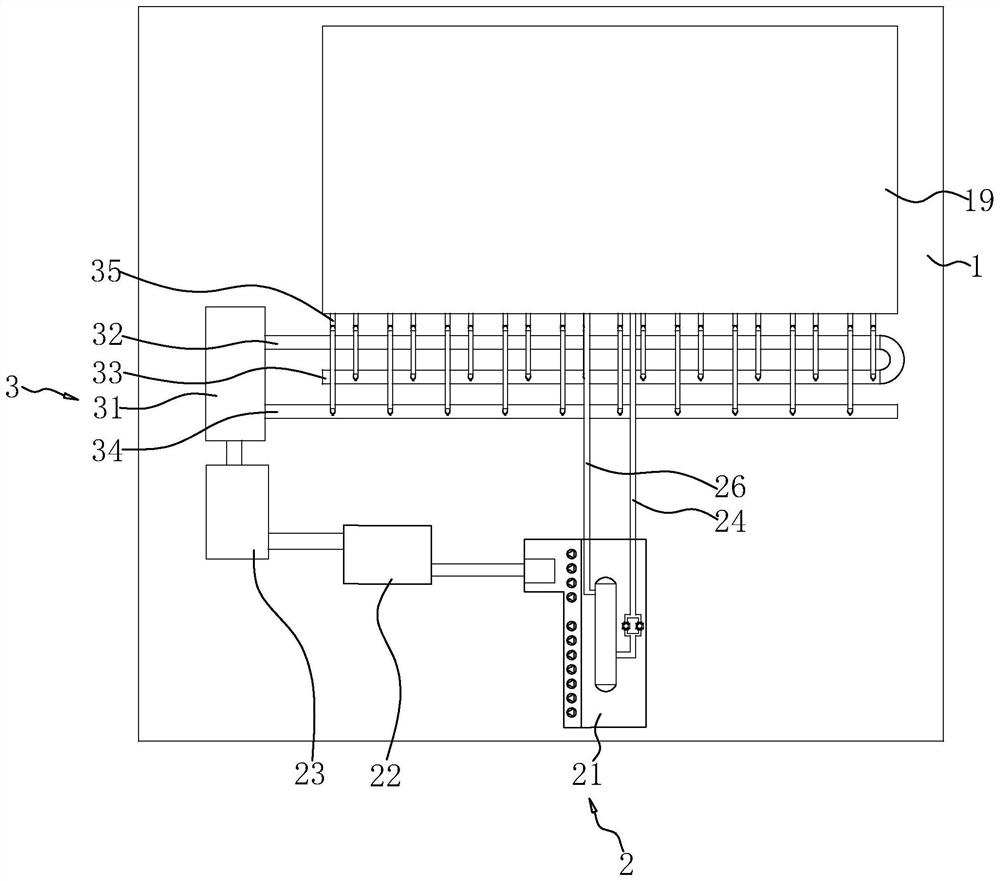

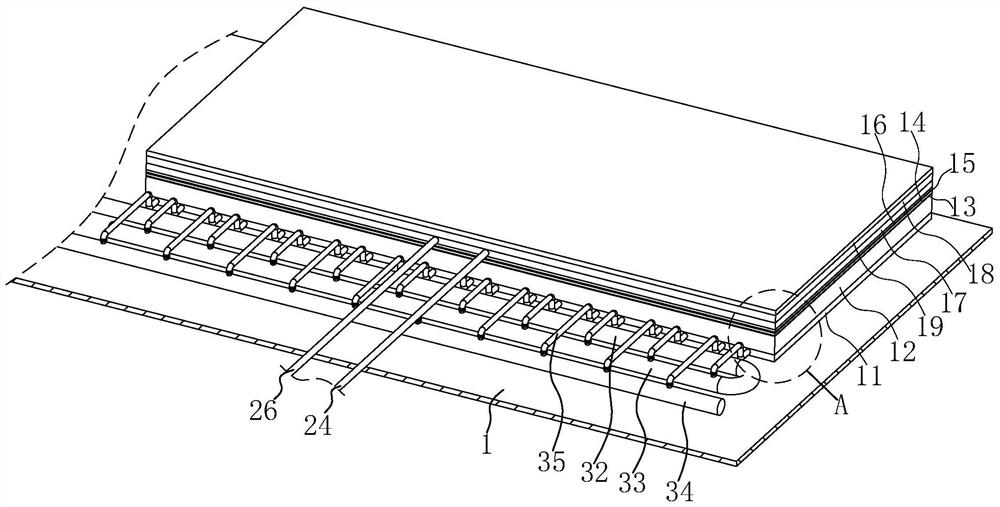

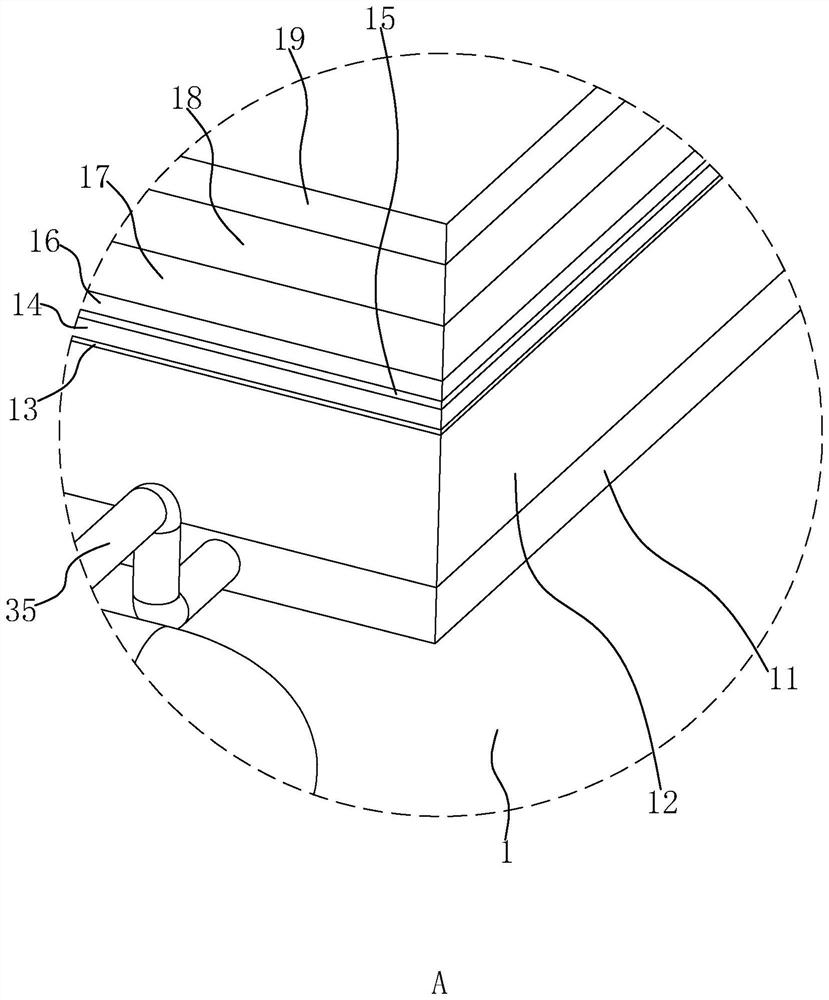

[0040] Attached to the following Figure 1-9 This application will be described in further detail.

[0041] The embodiment of the present application discloses a carbon dioxide transcritical direct cooling system for an ice skating rink. refer to figure 1 and figure 2 , the direct cooling system includes the original floor layer 1, and the original floor layer 1 is provided with a heating antifreeze layer 11, a cold insulation antifreeze layer 12, a sliding layer 13, a second protective layer 14, a waterproof layer 15, and a first protective layer from bottom to top. 16. The support layer 17 and the refrigeration layer 18; the support layer 17 and the refrigeration layer 18 are provided with a carbon dioxide refrigeration mechanism 2 for reducing the temperature of the refrigeration layer 18 to freeze the water on the refrigeration layer 18 into an ice layer 19, and the heating antifreeze layer 11 is provided The heat dissipation mechanism 3 for heating the heating antifre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com