Detection device for detecting bending degree of building H-shaped steel beam

A bending degree detection and detection device technology, which is applied in the direction of measuring device, electromagnetic measuring device, electric/magnetic profile/curvature measurement, etc., can solve problems such as time-consuming and laborious, great safety hazards, cracks in composite beams, etc., and achieve improvement The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

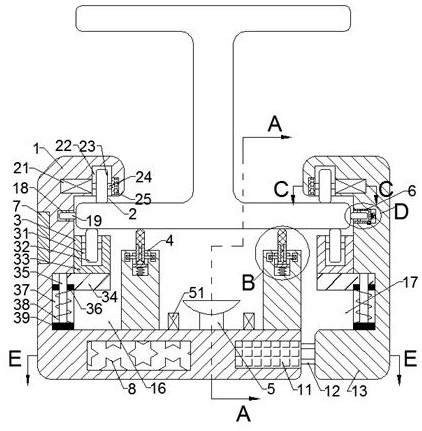

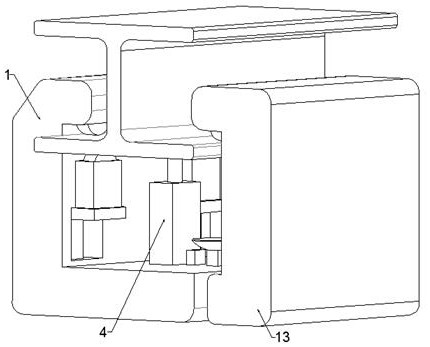

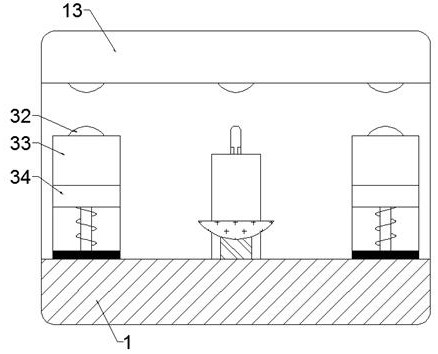

[0024] Such as Figure 1-7 As shown, a detection device for detecting the curvature of H-shaped steel girders in buildings includes a J-shaped first body 1 arranged on the lower side of the H-shaped steel girder, and a second body 1 is arranged on the right side of the first body 1. Two bodies 13, a first cavity 16 is provided in the right side wall of the first body 1, a second cavity 17 is provided in the left side wall of the second body 13, the first cavity 16 and the The second cavity 17 is equipped with three mobile wheel chambers 22 in an array on the upper side wall, and a walking mechanism 2 capable of walking on the H-shaped steel beam is provided in the mobile wheel chamber 22. The first cavity 16 Two sliding cavities 37 are arranged in an array on the side wall of the second cavity 17 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com