A mems probe structure for chip testing in ultra-high temperature working environment

A working environment and chip testing technology, applied in the field of MEMS probe structure, can solve the problems that the bare core test work cannot be completed, cannot be guaranteed, and the probe card is damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0091] The following is a specific embodiment of the MEMS probe structure for chip testing in an ultra-high temperature working environment of the present invention.

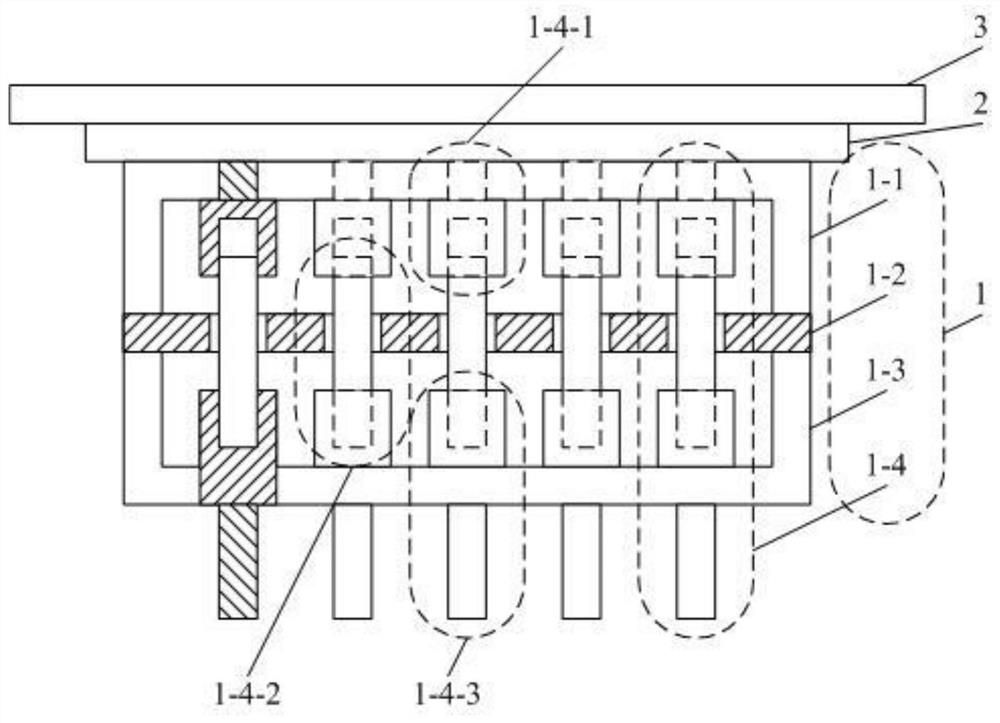

[0092] The structure of the MEMS probe for chip testing under the ultra-high temperature working environment in this embodiment is as follows: figure 1 As shown, the MEMS probe structure is provided with a PCB board 3, an adapter board 2 and a composite probe head structure 1 in sequence from top to bottom. The composite probe head structure 1 includes an upper guide plate 1-1 and a middle guide plate 1-2. and the lower guide plate 1-3, the probes 1-4 start from the adapter plate 2, pass through the upper guide plate 1-1 and the middle guide plate 1-2, and extend from the lower guide plate 1-3; among them, the upper guide plate 1-1 , the middle guide plate 1-2 and the lower guide plate 1-3 are made of insulating material, and the probe 1-4 is made of metal conductive material;

[0093] The probes 1-4 include an...

specific Embodiment approach 2

[0097] The following is a specific embodiment of the MEMS probe structure for chip testing in an ultra-high temperature working environment of the present invention.

[0098] The MEMS probe structure for chip testing in an ultra-high temperature working environment in this embodiment is based on the specific embodiment 1, and further defines that the middle probe 1-4-2 is made of at least one of antimony, bismuth or gallium. Made of metal alloy material. Since antimony, bismuth, and gallium are all substances that expand and contract with heat, they are often used to make alloys to reduce the influence of temperature on precision instruments. Therefore, using them to make the middle probe 1-4-2 can not only meet the electrical conductivity, but also can Realize thermal shrinkage and cold expansion characteristics.

[0099] In addition, the nickel sulfide used to make the tempered glass self-explode is also a substance that expands and contracts with cold, and can also be used...

specific Embodiment approach 3

[0100] The following is a specific embodiment of the chip testing method under the wide temperature range working environment of the present invention.

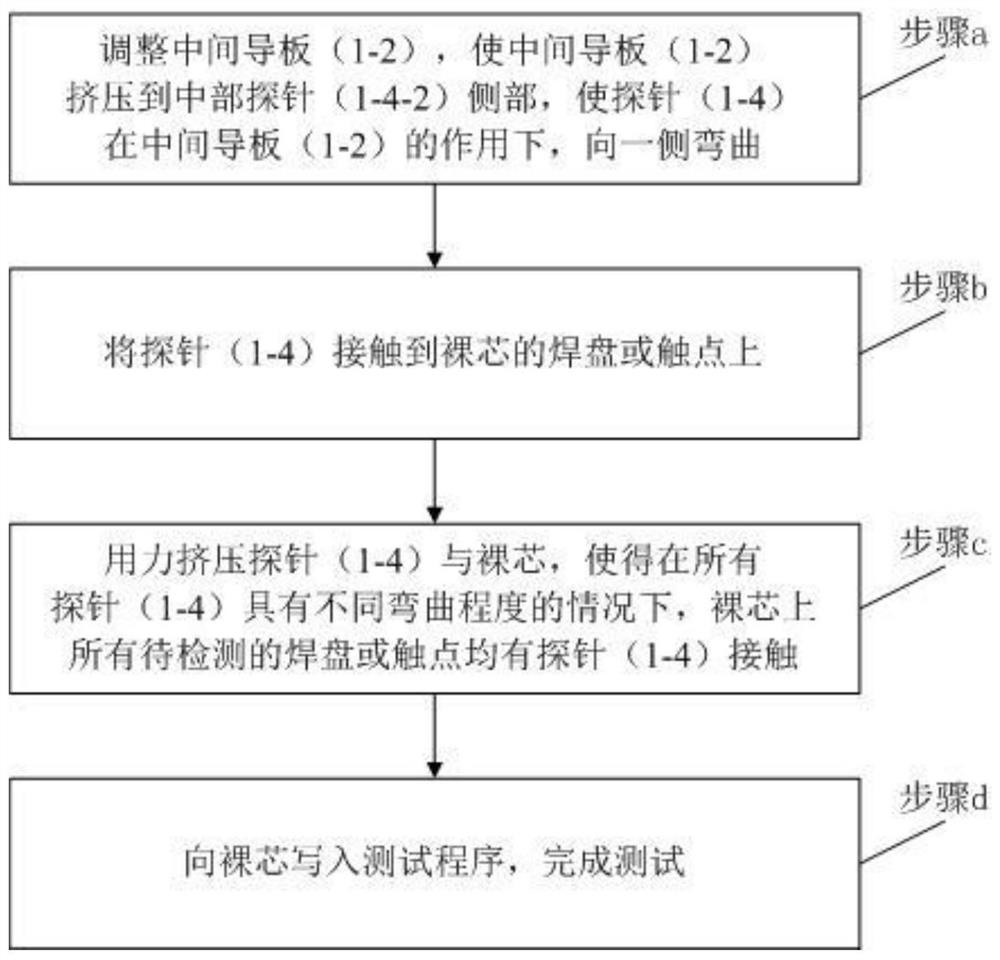

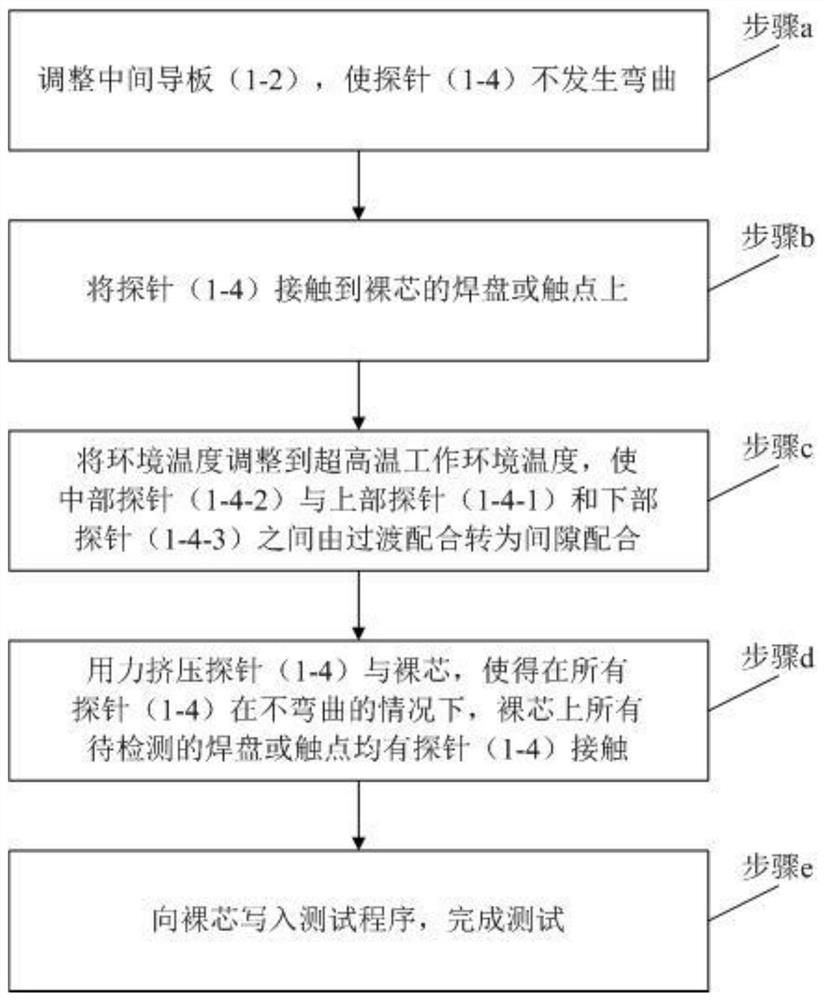

[0101] The chip testing method in the wide temperature range working environment in this embodiment is implemented on the MEMS probe structure for chip testing in the ultra-high temperature working environment described in the specific embodiment 1 or the specific embodiment 2. The wide temperature range working environment The lower chip testing method includes a chip testing method under a conventional temperature working environment and a chip testing method under an ultra-high temperature working environment, wherein the flow chart of the chip testing method under the conventional temperature working environment is as follows figure 2 As shown, the flow chart of the chip testing method in the ultra-high temperature working environment is as follows image 3 shown;

[0102] The normal temperature working environment refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com