Roller shutter type Fresnel lens array and light guide energy gathering system

A Fresnel lens and rolling shutter technology, applied in the field of light-guiding and concentrating systems, can solve the problems of large area, inability to rewind the Fresnel lens, difficult maintenance and replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment 1 describes a rolling-type Fresnel lens array to solve the problem that the Fresnel lens cannot be effectively protected due to the large area of a single Fresnel lens in the existing lens array and the difficulty of later maintenance and replacement lack of.

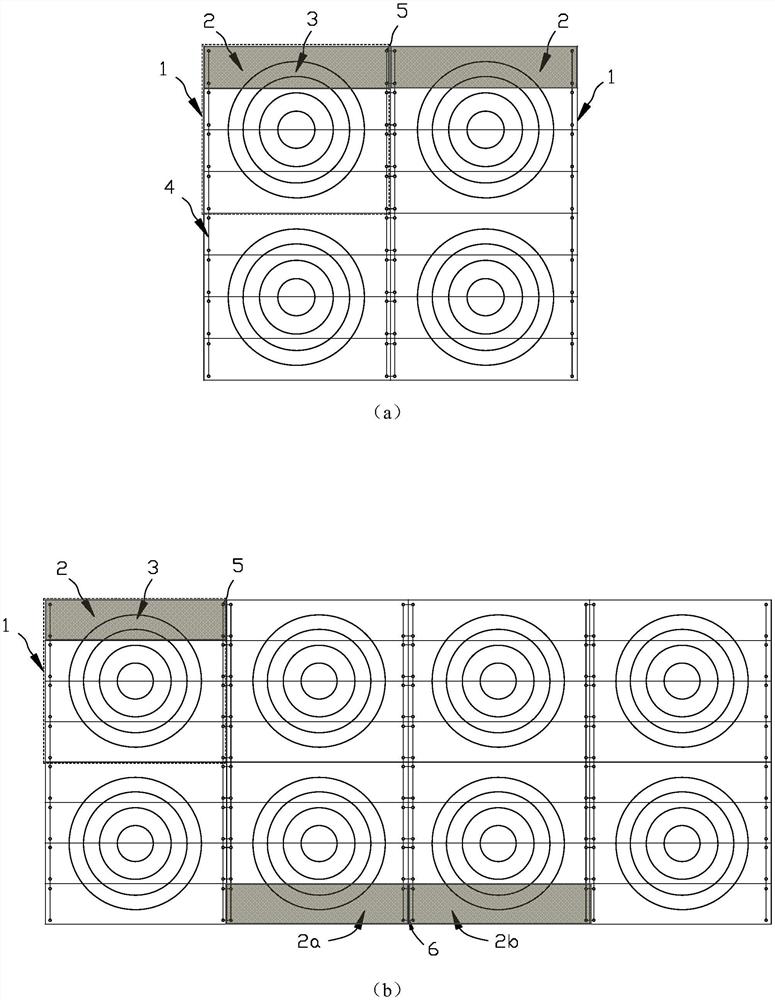

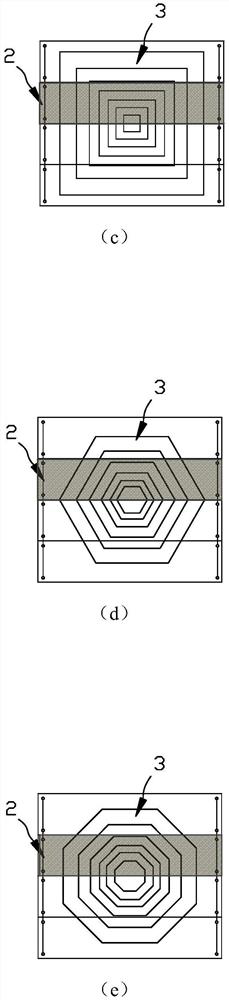

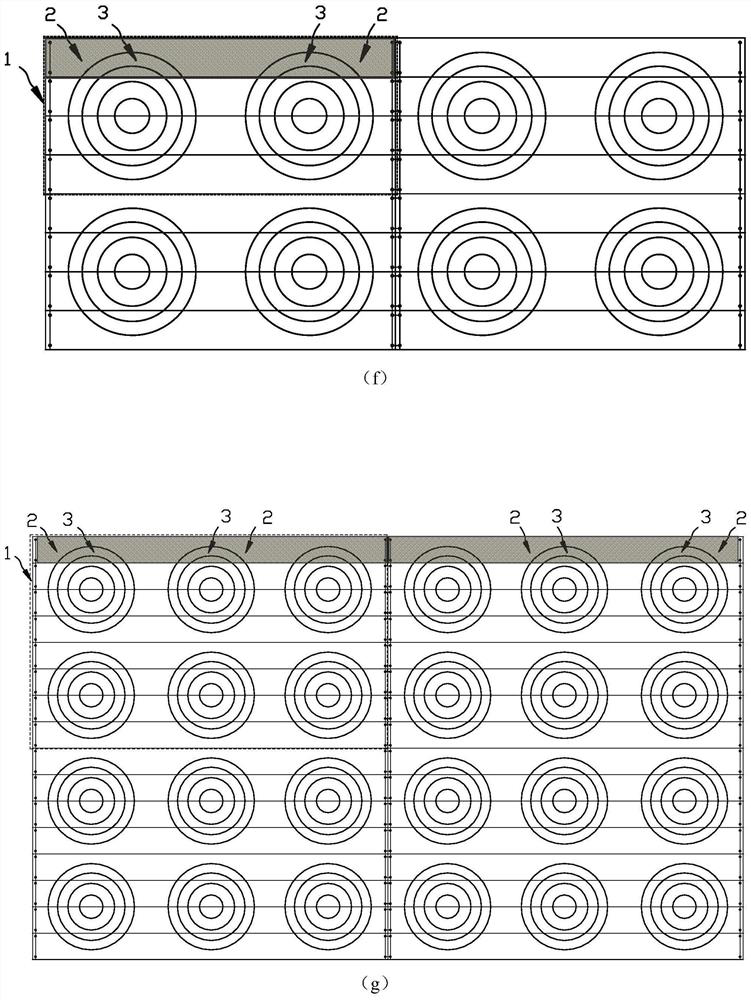

[0061] The rolling Fresnel lens array includes a plurality of Fresnel lens units 1, such as figure 1 (a), figure 1 (b), figure 1 (f) and figure 1 As shown in the dashed box in (g), all Fresnel lens units 1 are arranged in an array as a whole.

[0062] Such as figure 1 (a) the 2×2 array shown, or figure 1 (b) 2×4 array shown. Of course, the above is only exemplary, for example, a 1×2 array, a 2×3 array, a 3×3 array, or even more.

[0063] The structures of the above Fresnel lens units 1 are the same. Take one of the Fresnel lens units 1 as an example:

[0064] Each Fresnel lens unit 1 includes at least two Fresnel lens sheets 2 .

[0065] Wherein, each Fresnel lens sheet 2 is a rectangu...

Embodiment 2

[0119] This embodiment 2 describes a rolling-type Fresnel lens array. Except for the following technical features of the rolling-type Fresnel lens array, which are different from the above-mentioned embodiment 1, other technical features can refer to the above-mentioned embodiment 1. .

[0120] Such as image 3 As shown in (a), an anti-reflection film layer, such as a first anti-reflection film 7 , is provided on the upper surface of the Fresnel lens unit 1 . The first anti-reflection film 7 is attached to the upper surface of the Fresnel lens unit 1 .

[0121] The first anti-reflection coating 7 can reduce reflection, which is equivalent to increasing the intensity of incident light.

[0122] Or the lower surface of the Fresnel lens unit 1 is provided with an anti-reflection film layer, such as the second anti-reflection film 8, such as image 3 (b) shown. The second anti-reflection film 8 is attached to the lower surface of the Fresnel lens unit 2 .

[0123] The second ...

Embodiment 3

[0127] This embodiment 3 describes a rolling-type Fresnel lens array. Except for the following technical features of the rolling-type Fresnel lens array, which are different from the above-mentioned embodiment 1, other technical features can refer to the above-mentioned embodiment 1. .

[0128] Such as Figure 4 As shown, an anti-infrared membrane layer, such as an infrared-resistant membrane 9 , is provided on the upper surface of the Fresnel lens unit 1 .

[0129] When there is no need to increase heat in summer, by setting one deck of infrared-proof diaphragm 9, most (more than 80%) of infrared light can be cut off, thereby reducing heat conduction, helping to reduce indoor temperature and preventing local overheating.

[0130] Certainly, heat is needed during heating in winter, and at this moment, this layer of anti-infrared diaphragm 9 may not be provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com