Driving power supply and driving power supply glue injection method

A technology for driving power supply and power box, which is applied to electrical components, electrical equipment shells/cabinets/drawers, lighting and heating equipment, etc. It can solve the problems of insufficient glue filling for heat dissipation and complex structure, etc., and achieve easy control and assembly efficiency Lifting, easy-to-glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

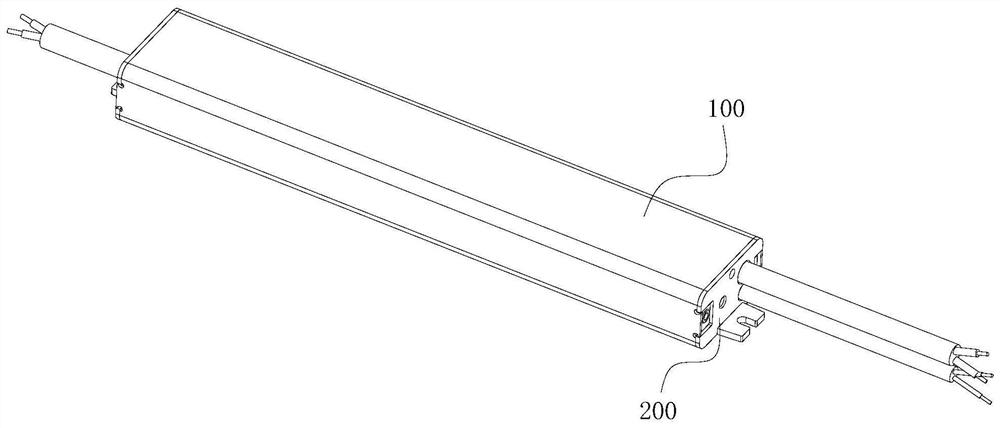

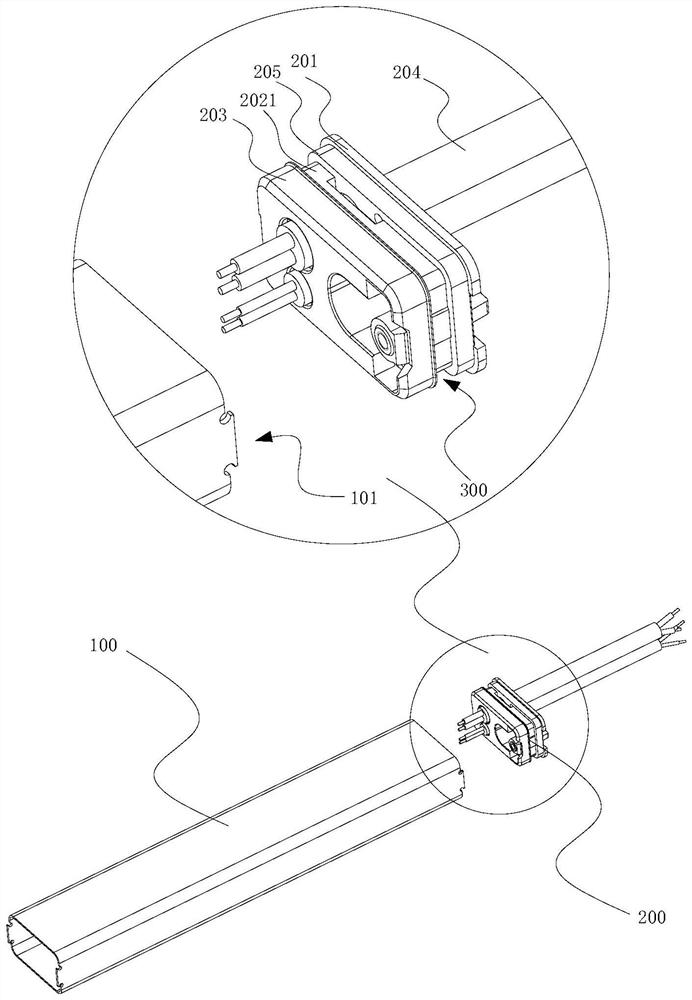

[0035] Such as Figure 1-7 As shown, the driving power supply of this embodiment includes a power supply box 100 and a circuit board 300 disposed in the power supply box 100, the power supply box 100 is provided with an installation port 101, and the installation port 101 is encapsulated by an end cover assembly 200 . The shape of the power supply box 100 can be set as required. In this embodiment, a common bar shape is adopted, with openings at both ends. The end cover assembly 200 of the embodiment can be used at either end, and only one end is used as an example below.

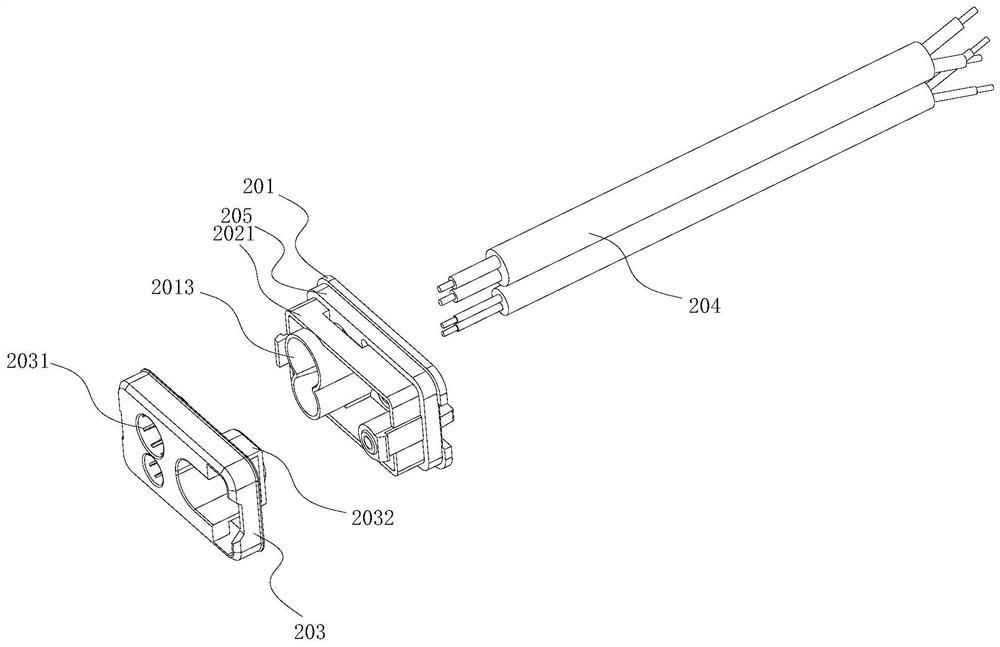

[0036] The end cover assembly 200 of this embodiment includes an outer cover 201 , a sealing plug 202 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com