Automatic travel system and harvester

A technology for automatic driving and harvesting machines, which is applied in the direction of harvesters, control/regulation systems, agricultural machinery and implements, etc., and can solve problems such as unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0108] Implementation of the first aspect:

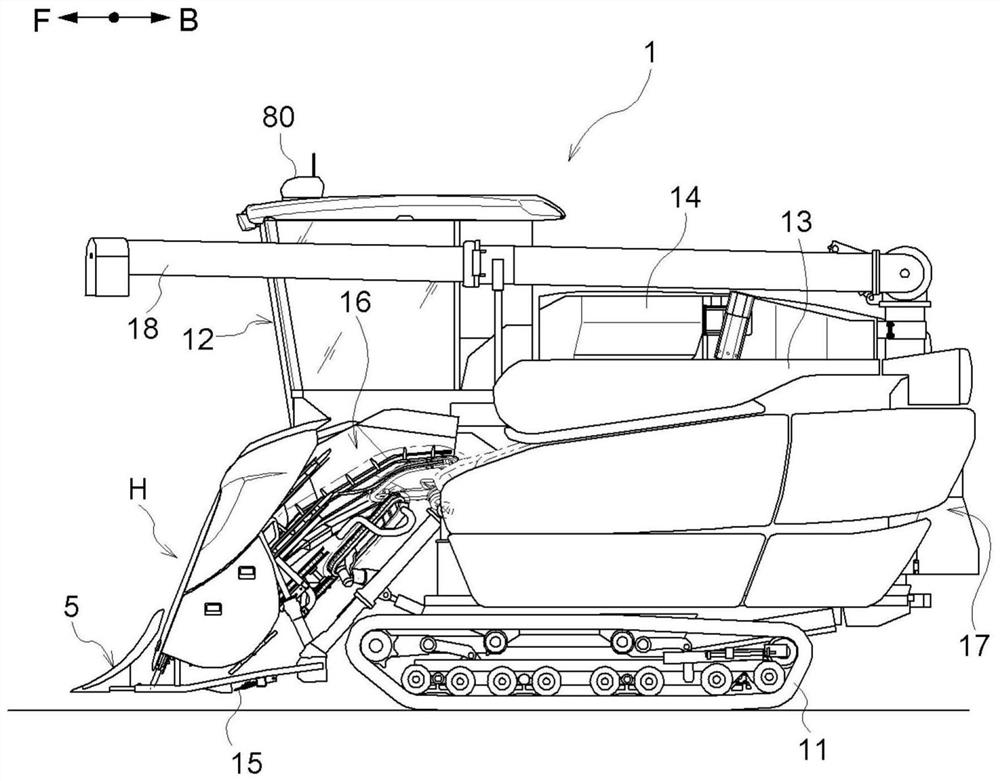

[0109] Embodiments for implementing the present invention will be described based on the drawings. In addition, in the following description, unless otherwise specified, the front-back direction is described as follows. That is, when the machine body is traveling for work, the traveling direction on the forward side is "front", and the traveling direction on the backward side is "rear". Furthermore, based on the forward posture in the front-rear direction, the direction corresponding to the right side is "right", and the direction corresponding to the left side is "left".

[0110] In addition, in the same figure 1 In the related description, the direction of the arrow F is referred to as "front", and the direction of the arrow B is referred to as "rear".

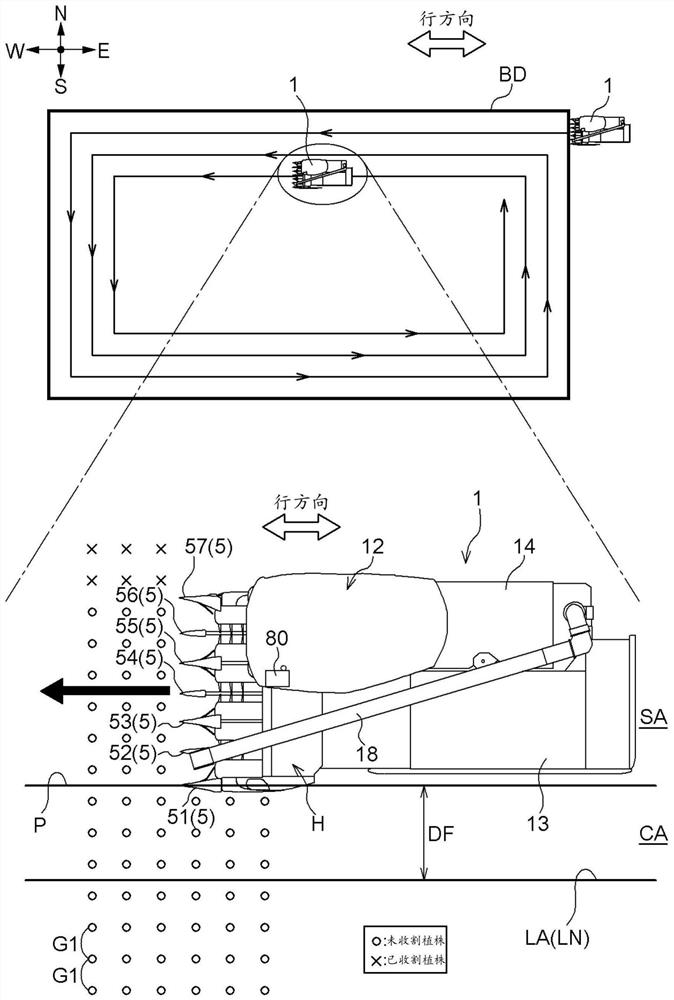

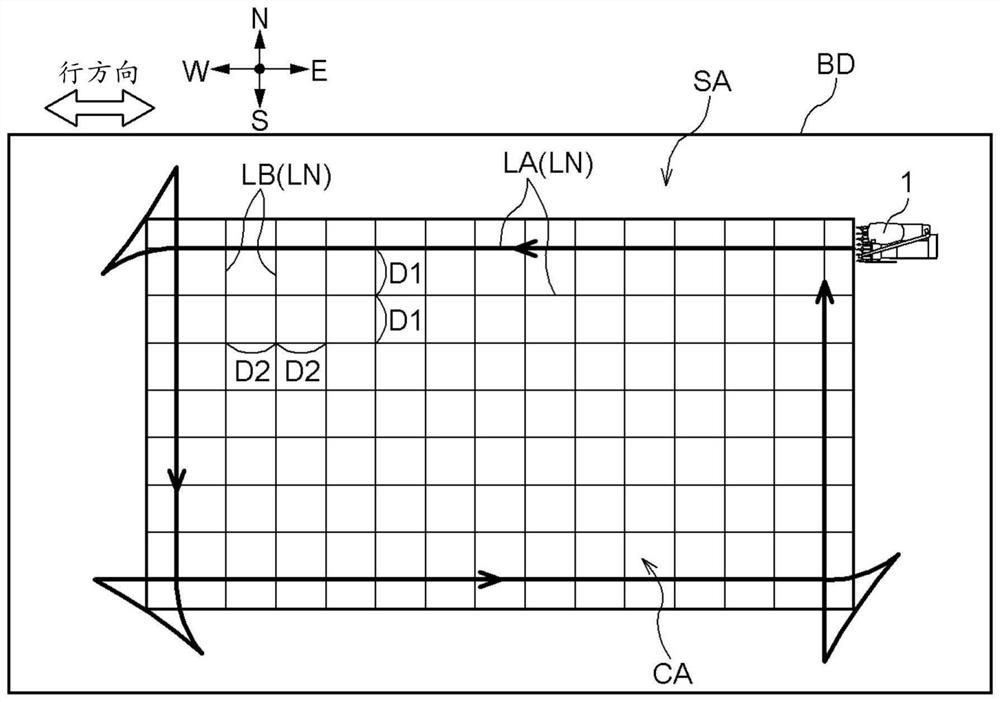

[0111] Additionally, the Figure 2 to Figure 4 , Figure 6 to Figure 13 , Figure 16 to Figure 18 The direction of the arrow N shown is "north", the direction of the arrow S...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap