Safety protection mask for chemical industry processing

A technology for safety protection and chemical industry, applied in the field of safety protection masks for chemical industry processing, can solve the problems of affecting the ventilation effect of the mask, harmful chemical reagents, reducing the contact effect between the coating net and the chemical reagents, etc. The effect of avoiding a decrease in air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

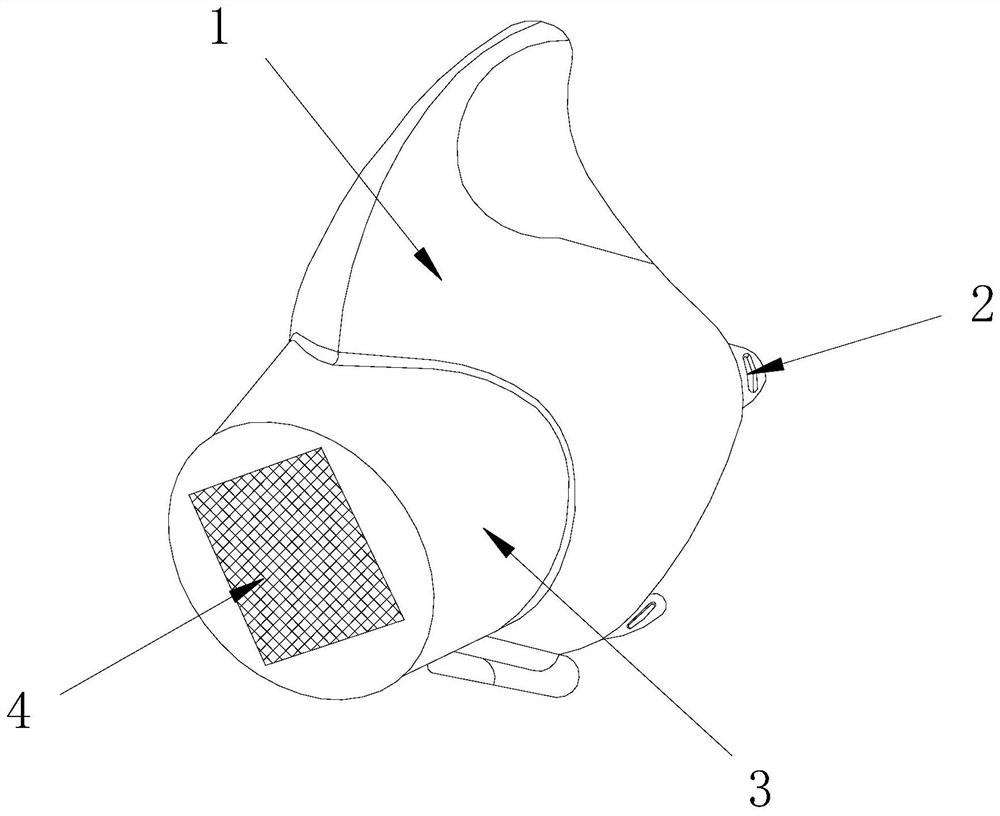

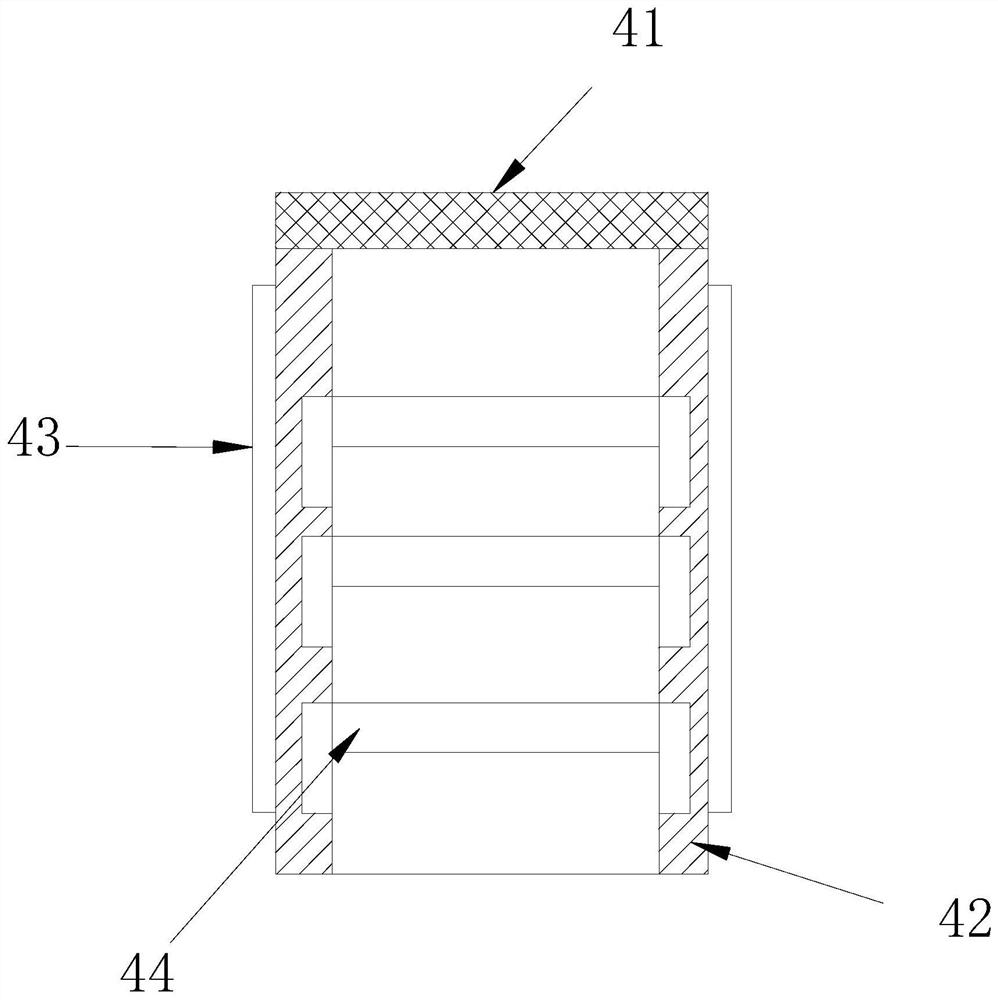

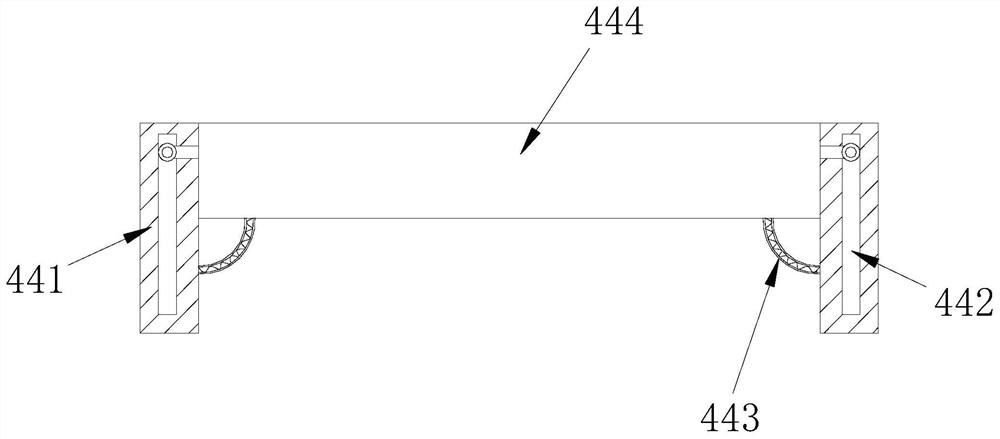

[0026] see Figure 1-Figure 6 , the specific embodiments of the present invention are as follows: a safety protection mask for chemical industry processing, its structure includes a cover body 1, a terminal block 2, a fixed block 3, a breathing tube 4, the right side of the cover body 1 and the left side of the terminal block 2 Embedded connection, the fixed block 3 is embedded in the front of the cover body 1, and the outer layer of the breathing tube 4 is embedded and connected with the inner wall of the fixed block 3; the breathing tube 4 includes a mesh cover 41, a tube wall 42, a connecting block 43, Coating structure 44, the bottom surface of the net cover 41 is embedded and connected with the top surface of the pipe wall 42, the inner layer of the connecting block 43 is embedded in the outer layer of the pipe wall 42, and the two sides of the coating structure 44 are connected with the inner layer of the pipe wall 42. Embedded connection, the coating structure 44 is pro...

Embodiment 2

[0033] see Figure 7-Figure 8 The specific embodiment of the present invention is as follows: the shovel head B5 includes a sliding block B51, a hammer B52, an absorbing ball B53, and a shoveling structure B54, the inner layer of the sliding block B51 is movably engaged with the bottom of the hammer B52, and the absorbing The outer layer of the ball B53 is embedded and connected to the top surface of the sliding block B51, the bottom of the scooping structure B54 is embedded in the inside of the sliding block B51, and there are four throwing hammers B52, and the gaps between the four throwing hammers B52 are evenly distributed on the sliding block The inner layer of B51 is beneficial to increase the impact strength generated by the swing when pushing out.

[0034] Wherein, the scooping structure B54 includes a supporting plate C1, a contact plate C2, a lower feeding groove C3, a contact frame C4, and a bouncing ball C5. The top surface of the supporting plate C1 is embedded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com