Double-deck vibrating screen for asphalt mixing plant

A double-layer vibrating screen and asphalt mixing plant technology, which is applied in the fields of filter screen, solid separation, chemical instruments and methods, etc., can solve the problems that asphalt is not easy to clean quickly, and achieve the effect of fast speed and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

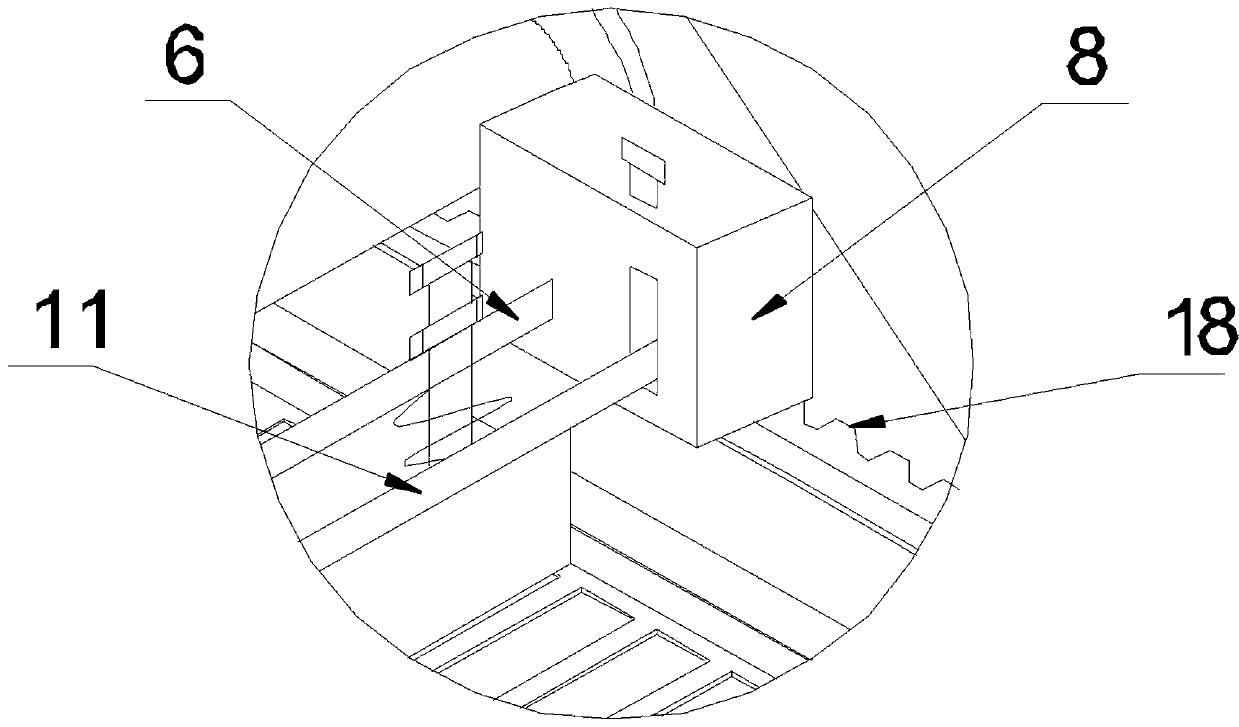

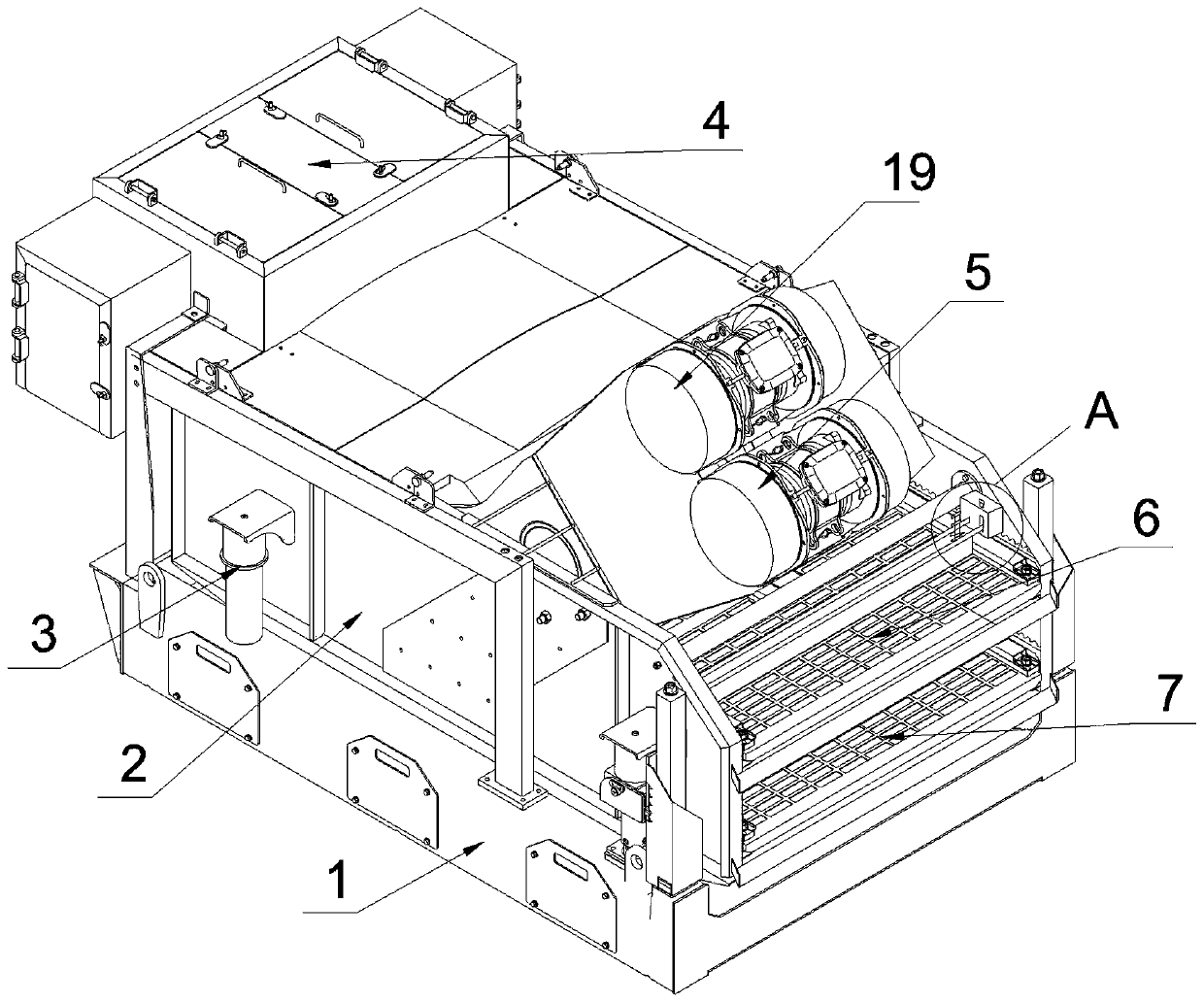

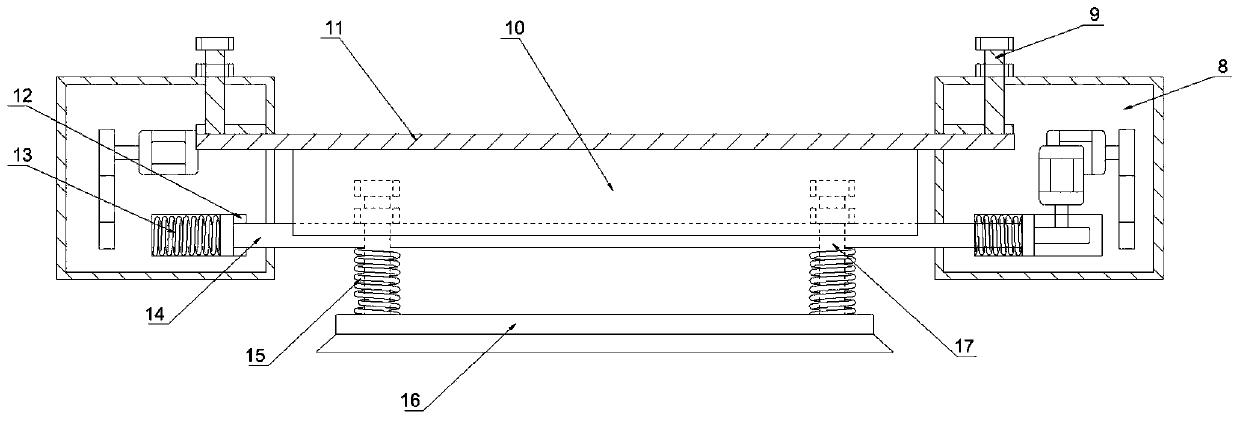

[0030] A double-layer vibrating screen for an asphalt mixing plant, comprising a vibrating screen main body, a fine-mesh stainless steel plate screen 7 and a coarse-mesh stainless steel plate screen 6 in the vibrating sieve main body, and the inner wall of the vibrating screen main body is symmetrically arranged along the opening direction of the fine-mesh stainless steel plate screen 7 There are two groups of parallel slide rails 18, and the two groups of slide rails 18 are respectively arranged above the fine-mesh stainless steel plate screen 7 and the coarse-mesh stainless steel plate screen 6. The slide rails 18 are all provided with slide boxes 8 that independently slide and cooperate with them. Sliding box 8 is connected by the first slide beam 11, the second slide beam 14, and the first slide beam 11 is connected with the shovel plate 10 that contacts with the fine-mesh stainless steel plate screen 7 or the coarse-mesh stainless steel plate screen 6, and the second slide ...

Embodiment 2

[0033] This embodiment is further optimized on the basis of implementation 1, specifically:

[0034] The main body of the vibrating screen includes a base 1, on which a screen box 2 is connected through a vibration isolation spring 3, a feeding box 4 connected to it is provided on one side above the screen box 2, and a driving coarse mesh is provided on the other side above the screen box 2. The first vibration motor 5 and the second vibration motor 19 of stainless steel plate screen 6 and fine mesh stainless steel screen 7 vibrate. The plate screen 7 is arranged below the coarse-mesh stainless steel plate screen 6 . The feeding box 4 feeds the material, and the input raw materials enter the coarse-mesh stainless steel screen 6, the first vibration motor 5 drives the coarse-mesh stainless steel screen 6 to vibrate, and the large particles are discharged through the opening on one side of the coarse-mesh stainless steel plate, and some raw materials pass through the coarse-mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com