Construction waste recycling device and recycling process thereof

A construction waste and recycling device technology, which is applied in the direction of construction waste recycling, recycling technology, magnetic separation, etc., can solve the problems of reducing the efficiency of construction waste recycling and cumbersome procedures, and achieve the goal of improving recycling quality, reducing wear and tear, and improving recycling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

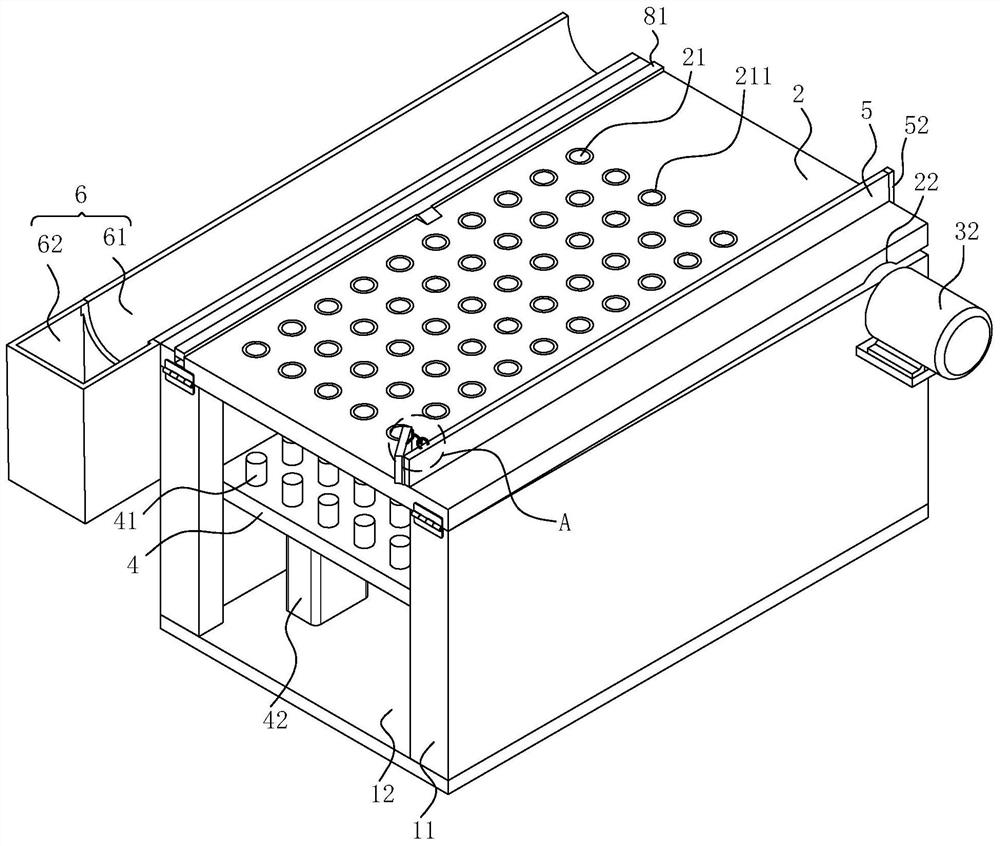

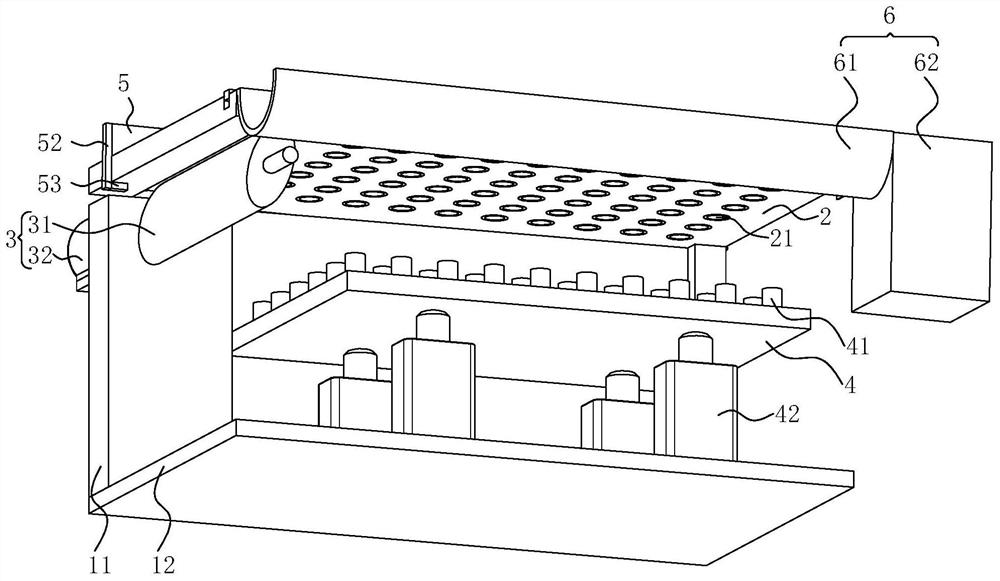

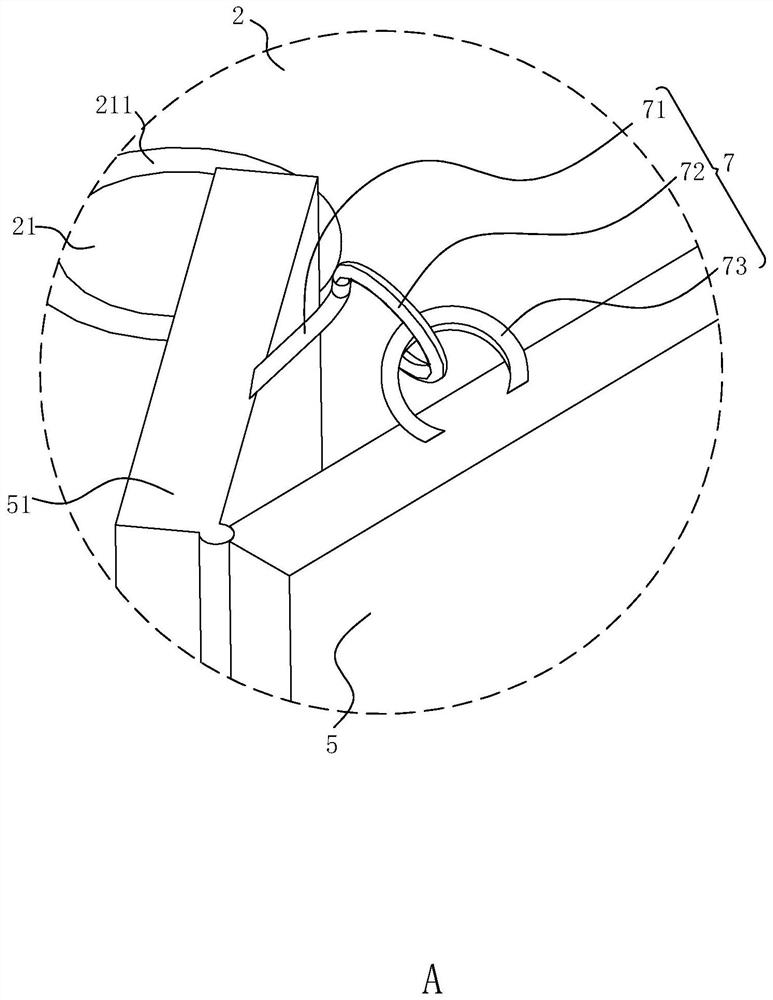

[0044] The following is attached Figure 1-5 The application is described in further detail.

[0045] The embodiment of the present application discloses a construction waste recycling device.

[0046] refer to figure 1 , a construction waste recovery device comprising a support frame 1, the support frame 1 is formed by fixing a vertical plate 11 and a horizontal plate 12, the vertical plate 11 is vertically arranged, two vertical plates 11 are provided and are parallel to each other, and the horizontal plate 12 is fixed on the bottom of the vertical plate 11, the top of the adjacent vertical plate 11 is provided with a sieve plate 2, the sieve plate 2 is a sieve plate 2 made of magnetic material, the sieve plate 2 is a rectangular strip plate, and the sieve plate 2 is provided with a A plurality of filter holes 21, the sieve plate 2 is arranged horizontally, and the scraper 5 is slidably arranged on the sieve plate 2; the supporting plate 4 is slidably arranged on the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com