Foaming equipment for foamed plastic product production

A foaming equipment and technology of foamed plastics, applied in the field of foamed plastics, can solve problems affecting plastic foaming and coagulation, and achieve the effect of avoiding air entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

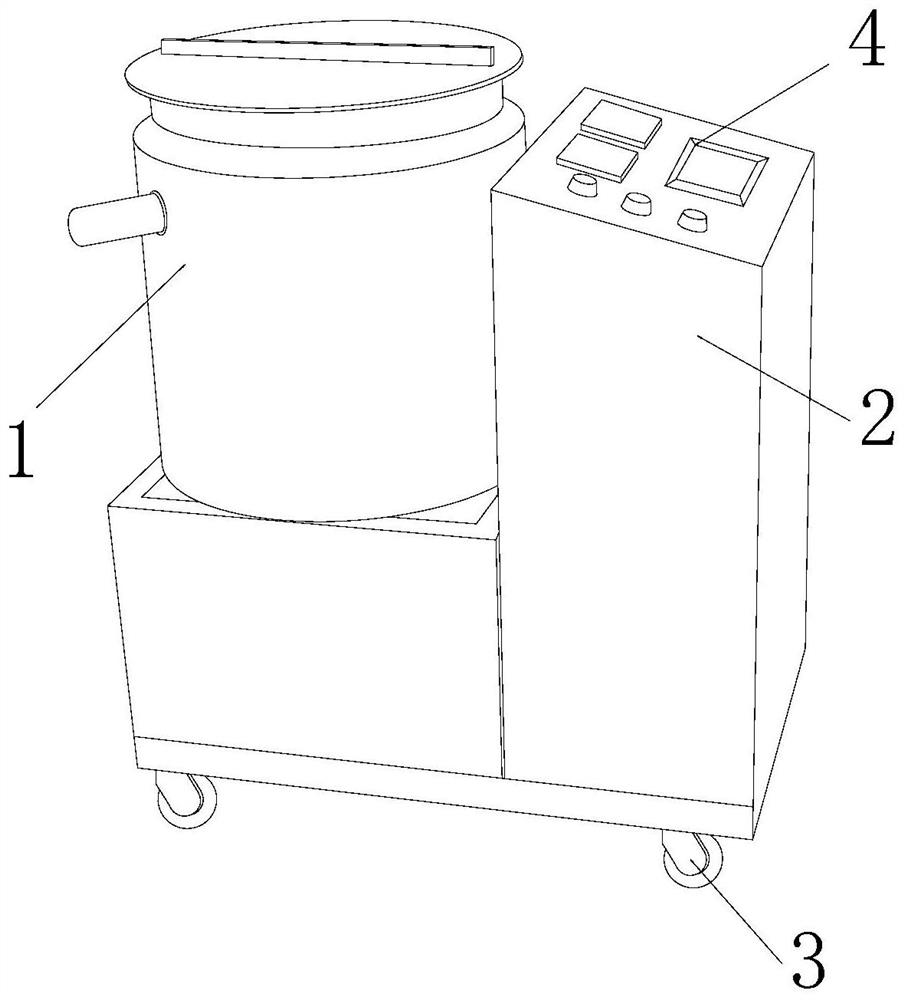

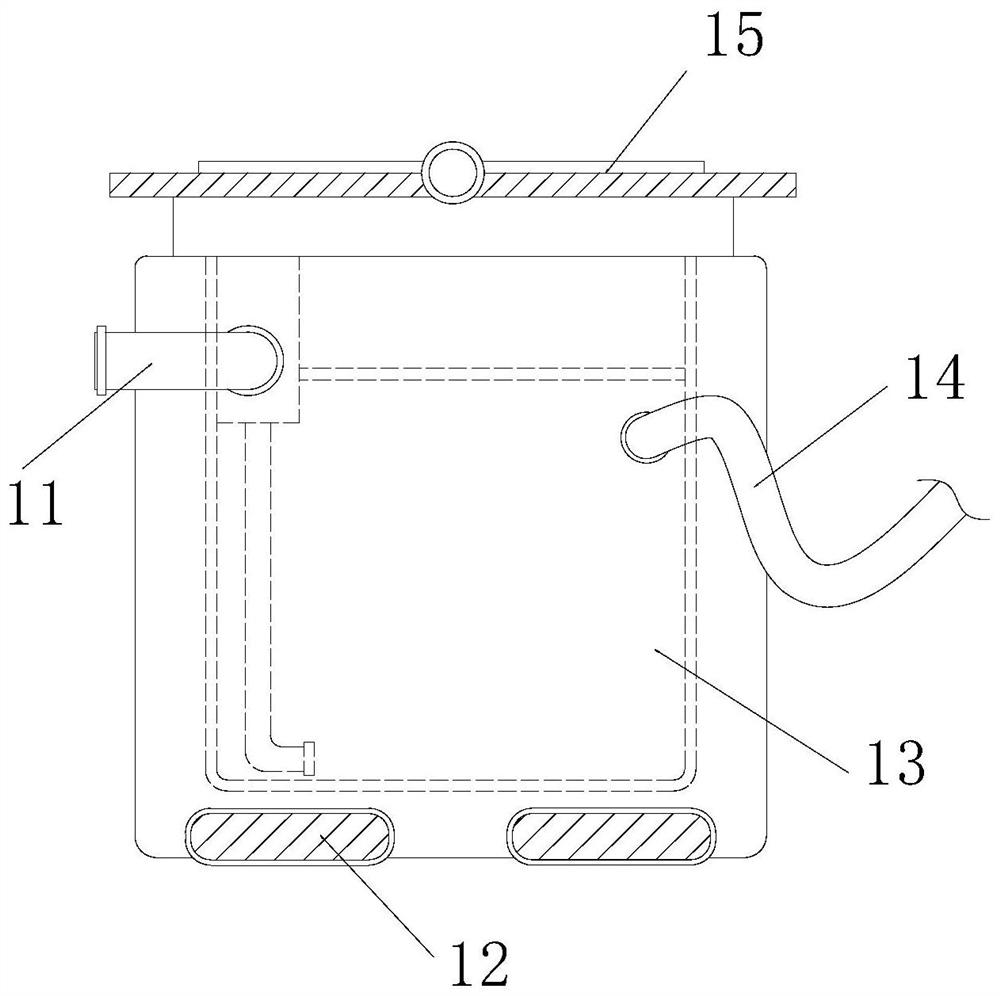

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The present invention provides a foaming equipment for the production of foamed plastic products. Its structure includes a foaming device 1, a body 2, a moving wheel 3, and a control panel 4. The foaming device 1 is installed on the left side of the body 2 by welding On the upper end surface, the upper end surface of the body 2 is inlaid with a control panel 4, the moving wheel 3 is embedded on the lower end surface of the body 2, and the control panel 4 is located on the right side of the foaming device 1; The foaming device 1 comprises an extracting device 11, a heater 12, a placement bucket 13, a foaming agent tube 14, and a hatch cover 15. The extracting device 11 is embedded and installed on the inner left end surface of the foaming device 1, and the heater 12 Symmetrically installed on the left and right sides of the lower end of the placement bucket 13, the placement bucket 13 is inlaid on the inner end s...

Embodiment 2

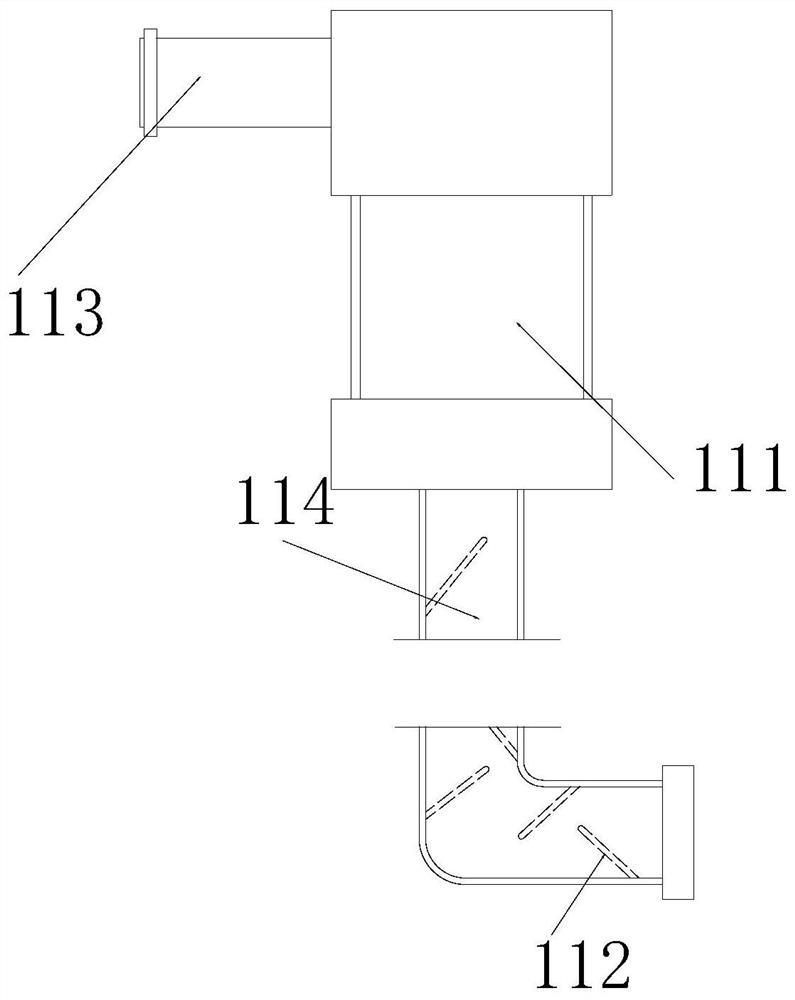

[0033] as attached Image 6 to attach Figure 7 Shown:

[0034]Wherein, the embedded pipe 113 includes an elastic piece 131, a closing block 132, a push ring 133, and a slide groove 134. The elastic piece 131 is embedded and engaged on the left end surface of the push ring 133, and the closing block 132 is symmetrically installed on the The upper and lower ends of the right side of the push ring 133, the push ring 133 is embedded in the inner end surface of the chute 134, the chute 134 is located on the right side of the elastic sheet 131, the right end surface of the push ring 133 is from the left The diameter gradually decreases to the right to form a slope, which can push up the closing block 132 when it is embedded in the closing block 132 .

[0035] Wherein, the closing block 132 includes a second rubber block 321, a magnetic block 322, a rotating shaft 323, and a swing block 324. The second rubber block 321 is inlaid on the upper end surface of the magnetic block 322, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com