Tow collecting equipment for carbon fiber production

A carbon fiber and equipment technology, applied in the field of wire collection, can solve the problems of large mold width, affecting the beauty of the wire, and clutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

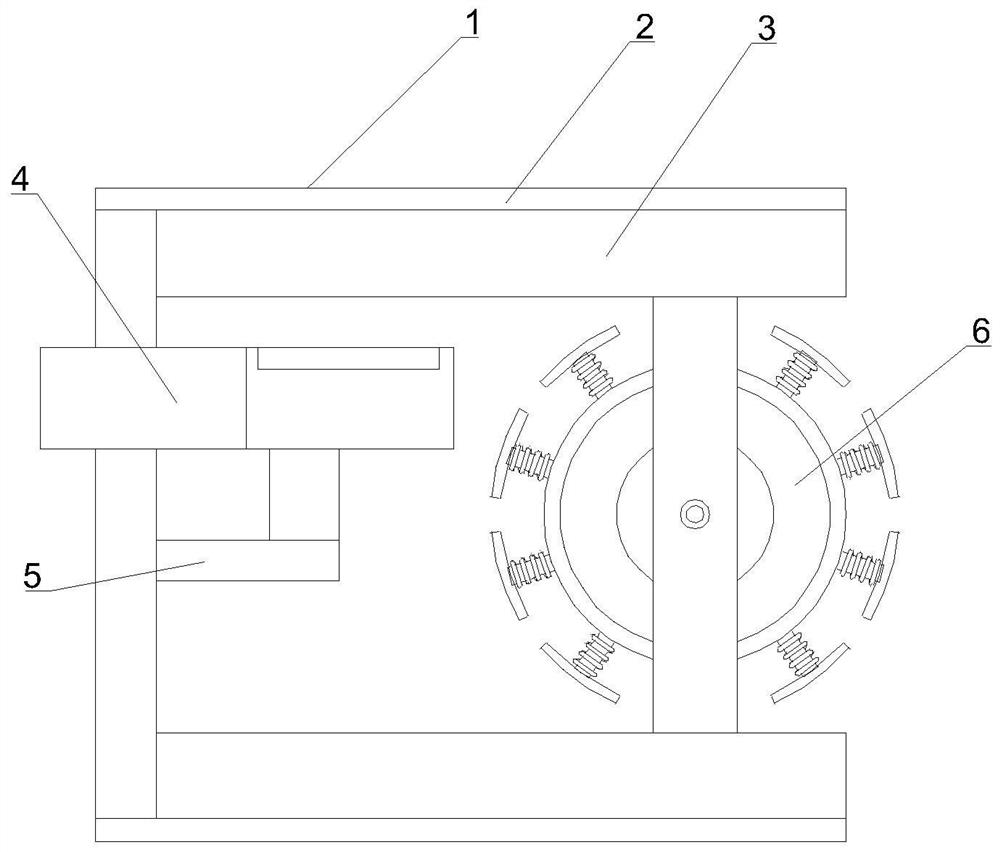

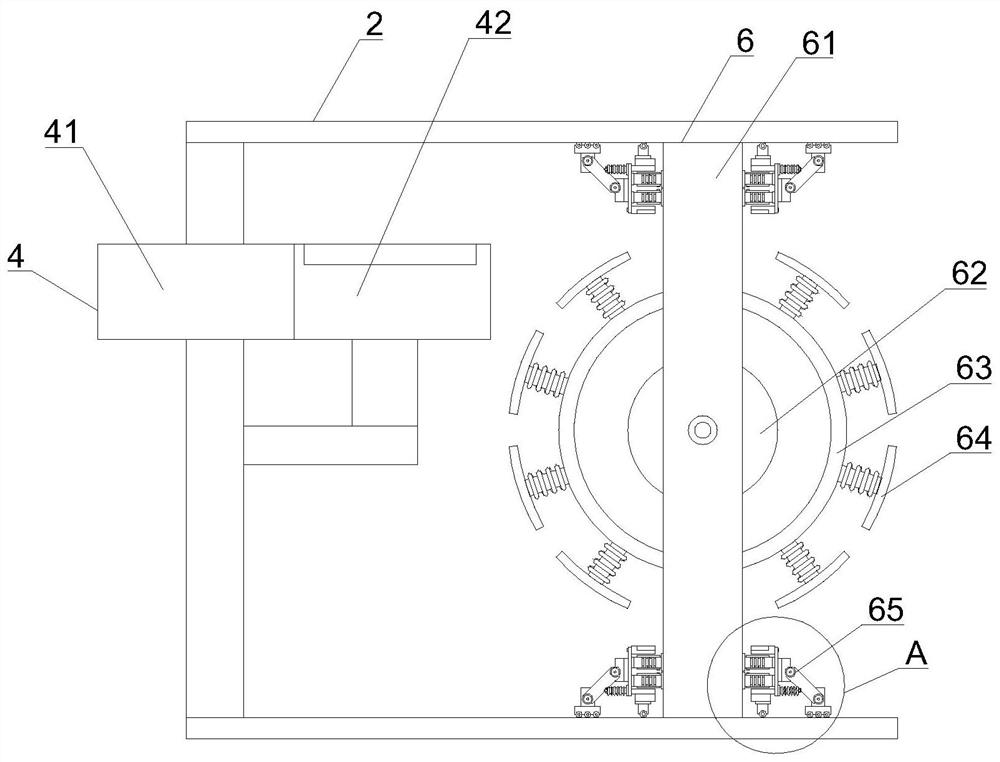

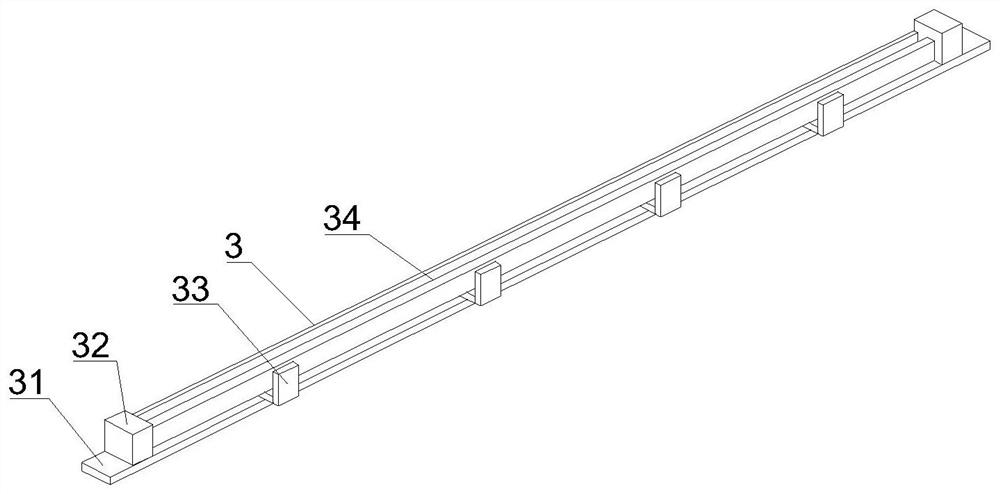

[0056] like Figure 1-10 As shown, the present invention provides a tow collection device for carbon fiber production, including a tow collection device body 1, an outer frame 2, a slide rail groove 3 and a wire groove 4, and the tow collection device body 1 includes an outer frame 2. The outer surface of the outer frame 2 is fixedly connected with a slide rail groove 3, the inside of the outer frame 2 is provided with a wire passing groove 4, the outer surface of the outer frame 2 is fixedly connected with a supporter 5, and the inside of the slide rail groove 3 Active connection has receiving device 6.

[0057] The wire trough 4 includes a heating cylinder 41 , and a cooling cylinder 42 is fixedly connected to the outer surface of the heating cylinder 41 .

[0058] The collecting device 6 includes a pillar 61 , a slider 65 is fixedly connected to the outer surface of the pillar 61 , and the collecting device 6 includes a hub 64 .

[0059] In this embodiment, through the co...

Embodiment 2

[0062] like Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the heating cylinder 41 includes a casing 411, and the inside of the casing 411 is movably connected with an inner sliding column 412, and the outer surface of the inner sliding column 412 A heater 413 is arranged on the top, and one end of the inner sliding column 412 is fixedly connected with a line port 414. The cooling cylinder 42 includes a connecting column 421, and a rotating ring 422 is movably connected to the outer surface of the connecting column 421. The outer surface of the rotating ring 422 An arc connecting rod 423 is fixedly connected to the top, and an outer arc block 424 is fixedly connected to one end of the arc connecting rod 423 , and a cooling hole 425 is arranged on the upper surface of the outer arc block 424 .

[0063] In this embodiment, the thread passes through the thread opening 414, and the heater 413 is used to heat th...

Embodiment 3

[0065] like Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the hub machine 64 includes a second bottom plate 641, a spring post 642 is arranged on the outer surface of the second bottom plate 641, and one end of the spring post 642 Fixedly connected with a receiving groove 643, the collecting groove 643 includes a groove plate 6431, the outer surface of the groove plate 6431 is fixedly connected with a pusher 6432, and the outer surface of the groove plate 6431 is fixedly connected with a fixer 6433, and one end of the fixer 6433 is fixed A U-shaped sleeve 6434 is connected, and a hub block 6435 is fixedly connected to the outer surface of the U-shaped sleeve 6434 .

[0066] In this embodiment, the receiving grooves 643 are evenly distributed on the surface of the wire gathering machine 64, and then the pushing machine 6432 is extended to change the width between the collectors, and the collected wires are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com