Rim propeller and advancing tool adopting same

A thruster and rim technology, applied in the field of fluid thrusters, can solve the problems of not being able to use vortex energy well, affecting the stability of the thruster, unable to convert the propulsion power, etc. Production and maintenance costs, and the effect of improving propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

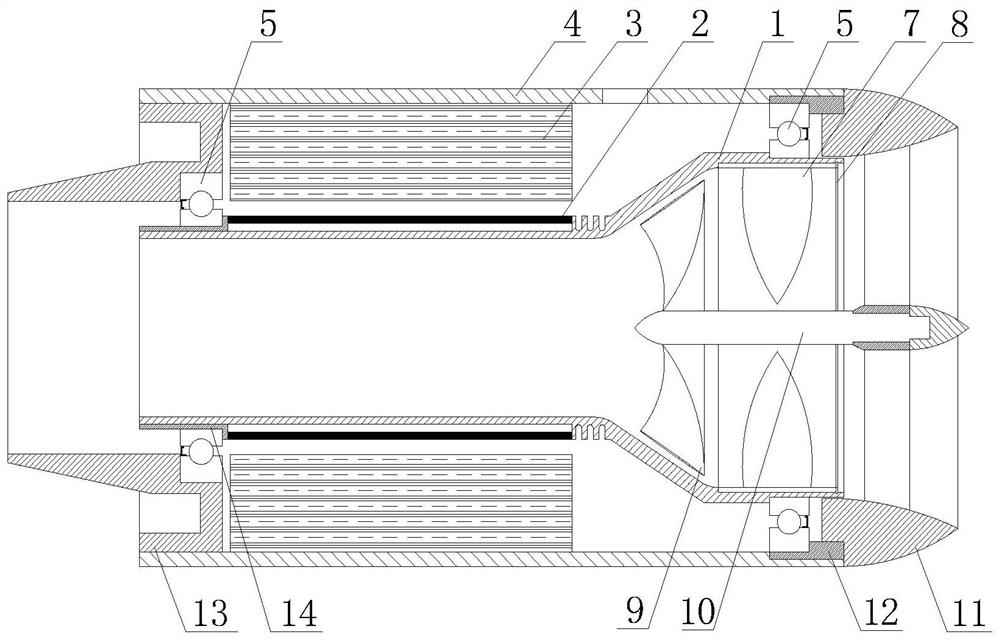

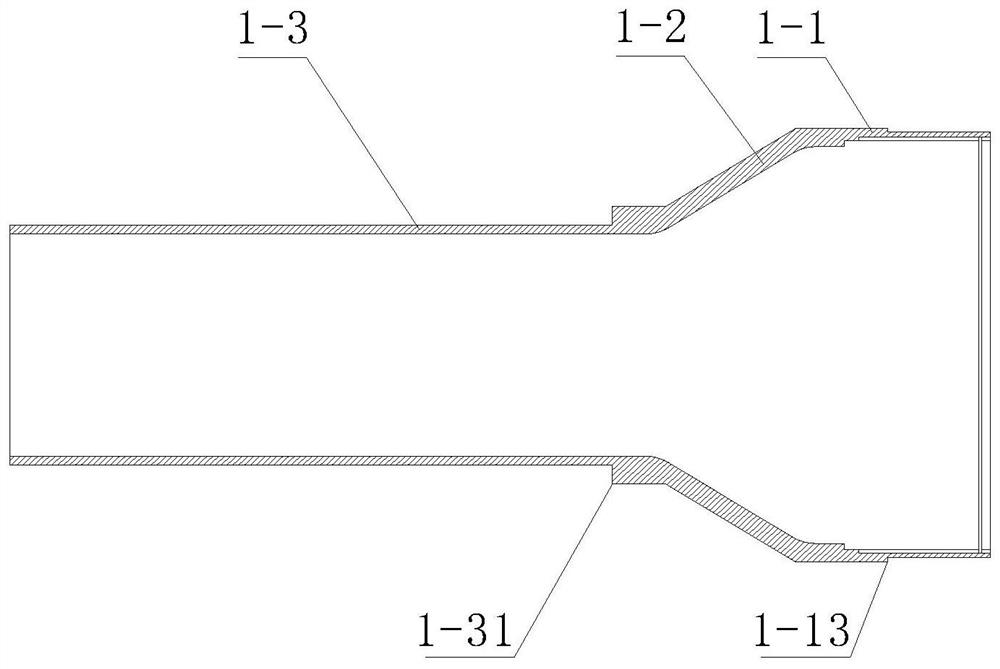

[0034] like Figure 1~3 As shown, a rim propeller includes a rotating shaft 1, a housing 4, a stator 3 and a rotor 2. The rotating shaft 1 is hollow and has a trumpet-like structure, and includes a large end portion 1-1, a small end portion 1- 3 and the transition portion 1-2 between the large end 1-1 and the small end 13-; the large end 1-1 is used to fix the propeller 7, and the small end 1-3 is used to fix The rotor 2 is installed; the rotating shaft 1 is fixedly installed in the housing 4 through the sealed bearing 5, the front end cover 12, the shaft sleeve 14 and the tail end cover 13; the stator 3 provides a radial rotating magnetic field for the rotor 2 to drive The rotor 2 drives the rotating shaft 1 to rotate.

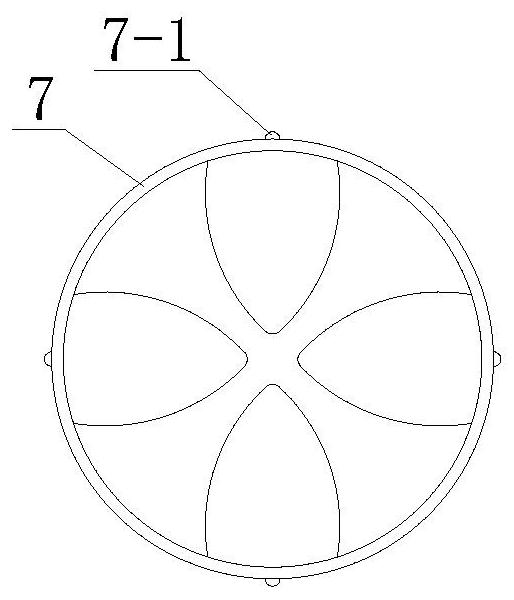

[0035] Further preferably, the propeller 7 is an integral rim type, and is detachably connected to the big end 1-1, and the inner circle of the big end 1-1 is provided with a semicircular keyway 1-11, The propeller 7 is provided with a convex line 7-1 that ...

Embodiment 2

[0038] like Figure 4-8 As shown, a rim propeller includes a rotating shaft 1, a housing 4, a stator 3 and a rotor 2. The rotating shaft 1 is hollow and has a trumpet-like structure, and includes a large end portion 1-1, a small end portion 1- 3 and the transitional portion 1-2 between the large end portion 1-1 and the small end portion 1-3; the large end portion 1-1 is used to fix the propeller 7, and the small end portion 1-3 is used for The rotor is fixedly installed; the rotating shaft 1 is fixedly installed in the housing 4 through the bearing 5, the front end cover 12, the shaft sleeve 14 and the tail end cover 13; the stator 3 provides a radial rotating magnetic field for the rotor 2 to drive the The rotor 2 drives the rotating shaft 1 to rotate.

[0039] Preferably, the propeller 7 is a combined rim type, and is detachably connected to the big end 1-1, and the inner circle of the big end 1-1 is provided with a semicircular keyway 1-11, so The propeller 7 is provided ...

Embodiment 3

[0042] like Figure 9 As shown, a rim propeller includes a rotating shaft 1, a housing 4, a stator 3 and a rotor 2. The rotating shaft 1 is hollow and has a trumpet-like structure, and includes a large end portion 1-1, a small end portion 1- 3 and the transitional portion 1-2 between the large end portion 1-1 and the small end portion 1-3; the large end portion 1-1 is used to fix the propeller 7, and the small end portion 1-3 is used for The rotor is fixedly installed; the rotating shaft 1 is fixedly installed in the housing 4 through the magnetic bearing 5, the front end cover 12, the shaft sleeve 14 and the tail end cover 13; the stator 3 provides a radial rotating magnetic field for the rotor 2 to drive The rotor 2 drives the rotating shaft 1 to rotate.

[0043] Preferably, the propeller 7 is detachably connected to the big end 1-1, the inner circle of the big end 1-1 is provided with a semicircular keyway 1-11, and the propeller 7 is provided with a large The end keyway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com