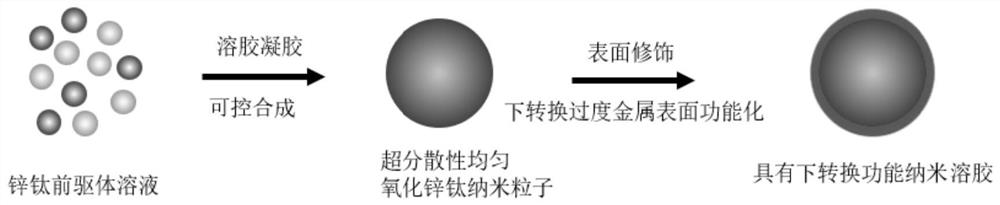

Zinc oxide titanium nano sol wrapped by rare earth metal organic complex and preparation method thereof

A technology of organic complexes and rare earth metals, applied in radiation-absorbing coatings, coatings, energy wastewater treatment, etc., can solve problems that affect the service life of coatings and solar panels, reduce energy utilization, yellowing or degradation, etc. , to achieve the effect of improving solar energy utilization, avoiding energy waste, and increasing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

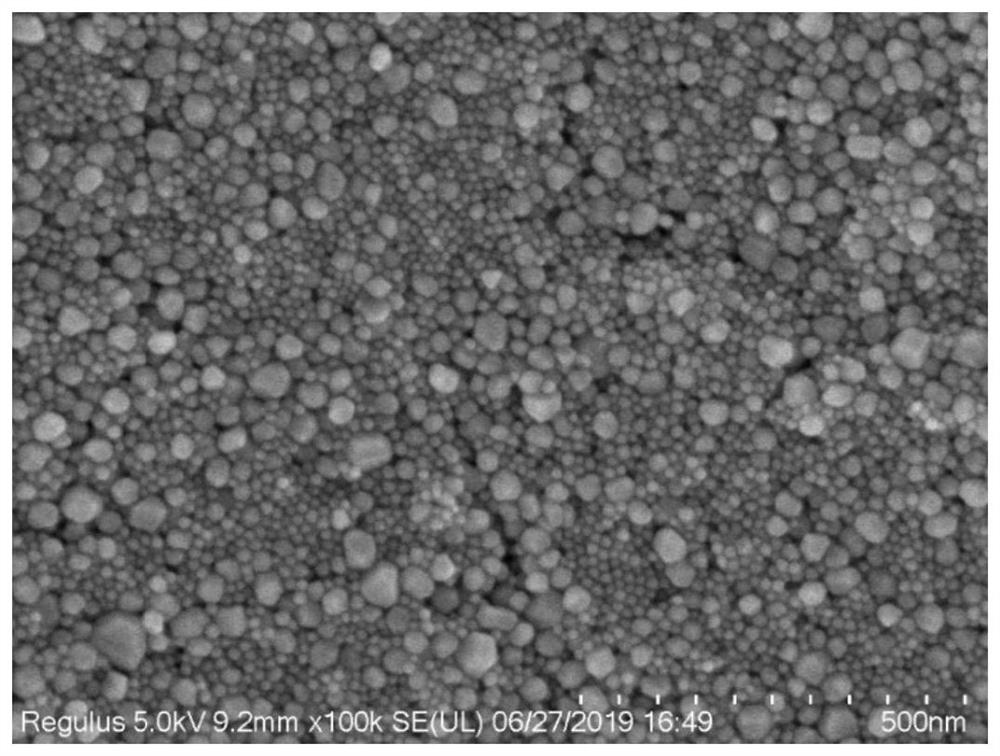

Examples

Embodiment 1

[0042] The preparation method of the zinc oxide-titanium nano-sol wrapped by a rare earth metal organic complex is as follows:

[0043] Add 250 g of absolute ethanol to the reactor, slowly add 40 g of isopropanol to the absolute ethanol, then add 20 g of zinc acetate, stir to dissolve, add 60 g of titanium tetraisopropoxide, and stir for 30 minutes to obtain a reaction solution. Then mix 18mL of water, 15mL of hydrochloric acid and 70mL of absolute ethanol evenly, and slowly add it dropwise to the reaction solution, stir for 24 hours, then raise the temperature to 80°C, and react for 2 hours, then add 3mL of 3-aminopropyltrimethoxy Silane, stirred for 12 hours, after centrifugal precipitation, added absolute ethanol and isopropanol to dissolve, then added 0.5g europium nitrate and 0.5g ytterbium nitrate, reacted at 80°C for 2h, then added 20g hexamethylenetetramine, 80 ℃ for 5 hours; after cooling down to room temperature, lyophilized for 24 hours to obtain Zn(x)Ti(y)O(x+2y): ...

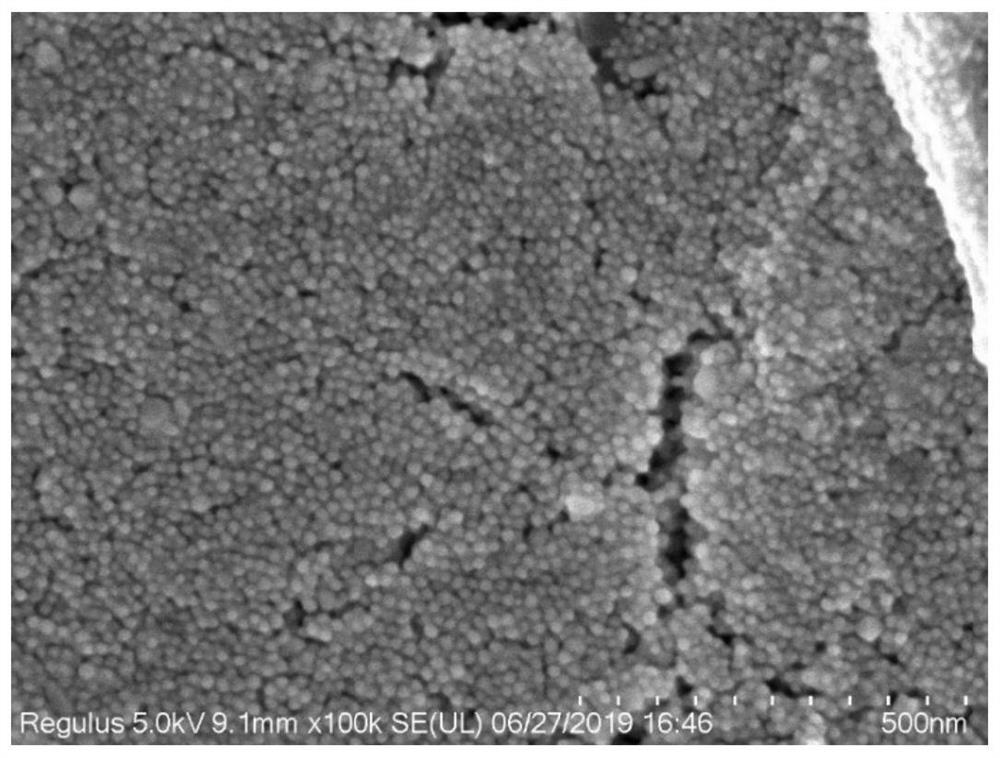

Embodiment 2

[0045] The preparation method of the zinc oxide-titanium nano-sol wrapped by a rare earth metal organic complex is as follows:

[0046] Add 250 g of absolute ethanol to the reactor, slowly add 40 g of isopropanol to the absolute ethanol, add 30 g of zinc nitrate, stir to dissolve, then add 40 g of tetrabutoxytitanium, and stir for 30 minutes to obtain a reaction solution. After mixing 18mL of water, 15mL of hydrochloric acid and 70mL of absolute ethanol, slowly add it dropwise to the reaction solution, stir for 24 hours, then raise the temperature to 80°C, and react for 2 hours, then add 3mL of 3-aminopropyltrimethoxysilane , stirred for 12 hours, centrifuged and precipitated, added absolute ethanol and isopropanol to dissolve, then added 0.6g neodymium nitrate and 1g ytterbium nitrate, reacted at 80°C for 2h, then added 20 acetylacetone, and reacted at 80°C for 5h; After room temperature, lyophilize and dry for 24 hours to obtain Zn(x)Ti(y)O(x+2y):Nd 3+ -Yb 3+ Organic compl...

Embodiment 3

[0048] The preparation method of the zinc oxide-titanium nano-sol wrapped by a rare earth metal organic complex is as follows:

[0049] Add 250 g of absolute ethanol to the reactor, slowly add 40 g of isopropanol to the absolute ethanol, add 30 g of zinc nitrate, stir to dissolve, then add 40 g of tetrabutoxytitanium, and stir for 30 minutes to obtain a reaction solution. After mixing 18mL of water, 15mL of hydrochloric acid and 70mL of absolute ethanol, slowly add it dropwise into the reaction solution, stir for 24 hours, then raise the temperature to 80°C, react for 2 hours, then add 3mL of tert-butylamine, stir for 12 hours, centrifuge and precipitate, Add absolute ethanol and isopropanol to dissolve, then add 0.5g ytterbium nitrate and 1g cerium nitrate, react at 80°C for 2h, then add 20g adipic acid, react at 80°C for 5h; after cooling down to room temperature, lyophilize for 24h , get Zn(x)Ti(y)O(x+2y):Ce 3+ -Yb 3+ Organic complex powder. Zn(x)Ti(y)O(x+2y):Ce 3+ -Yb ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap