Aeolian sand liquefaction ballasting earthing reinforcement equipment and ballasting method

A wind-blown sand and soil-covering technology, applied in soil protection, earth mover/shovel, grain processing, etc., can solve the problems of inflexible operation, cumbersome operation, time-consuming and laborious, etc., and achieve convenient disassembly and flexible operation , Easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

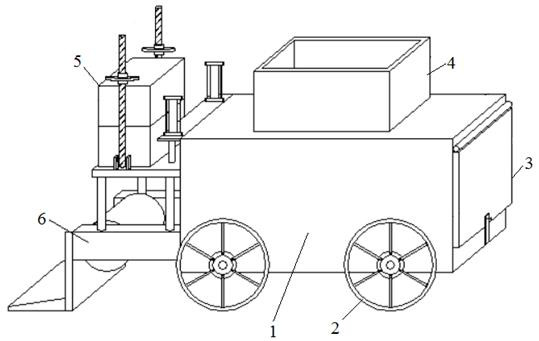

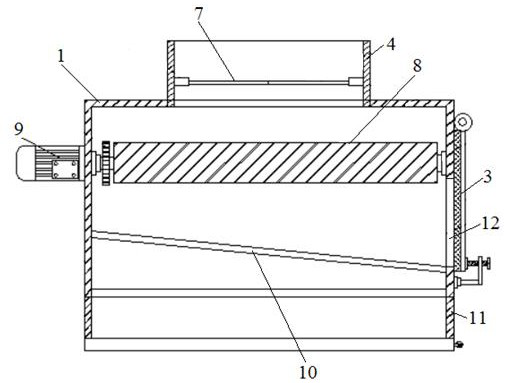

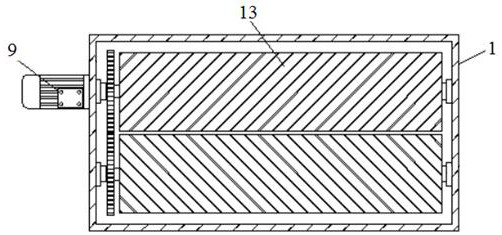

[0035] Such as figure 1 and figure 2 As shown, the pressure-reinforced soil reinforcement equipment of the present invention includes a hollow casing 1, a plurality of rollers 2 are installed at the bottom of the casing 1, and a feed inlet 4 communicating with the inside of the casing 1 is provided on the top of the casing 1. Inside the feed inlet 4, a The cover 7 can be opened and closed, and one end of the shell 1 is provided with a coarse material outlet 12; the coarse material outlet 12 is provided with a closing mechanism 3, and the other end of the shell 1 is equipped with a compacting mechanism 6, which 6 is provided with a counterweight mechanism 5; inside the shell 1, a crushing mechanism 8 and a screen 10 are installed in sequence from top to bottom; a motor 9 is installed on the outer wall of the shell 1, and the motor 9 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com