Fabricated beam-column connecting device and connecting method

A beam-column connection and prefabricated technology, which is applied in protective buildings/shelters, building components, and earthquake resistance, can solve problems such as time-consuming, poor structural stability and practicability, and affect the development of prefabricated buildings. Promote and develop obstacles, save time and material costs, enhance the effect of earthquake resistance and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention:

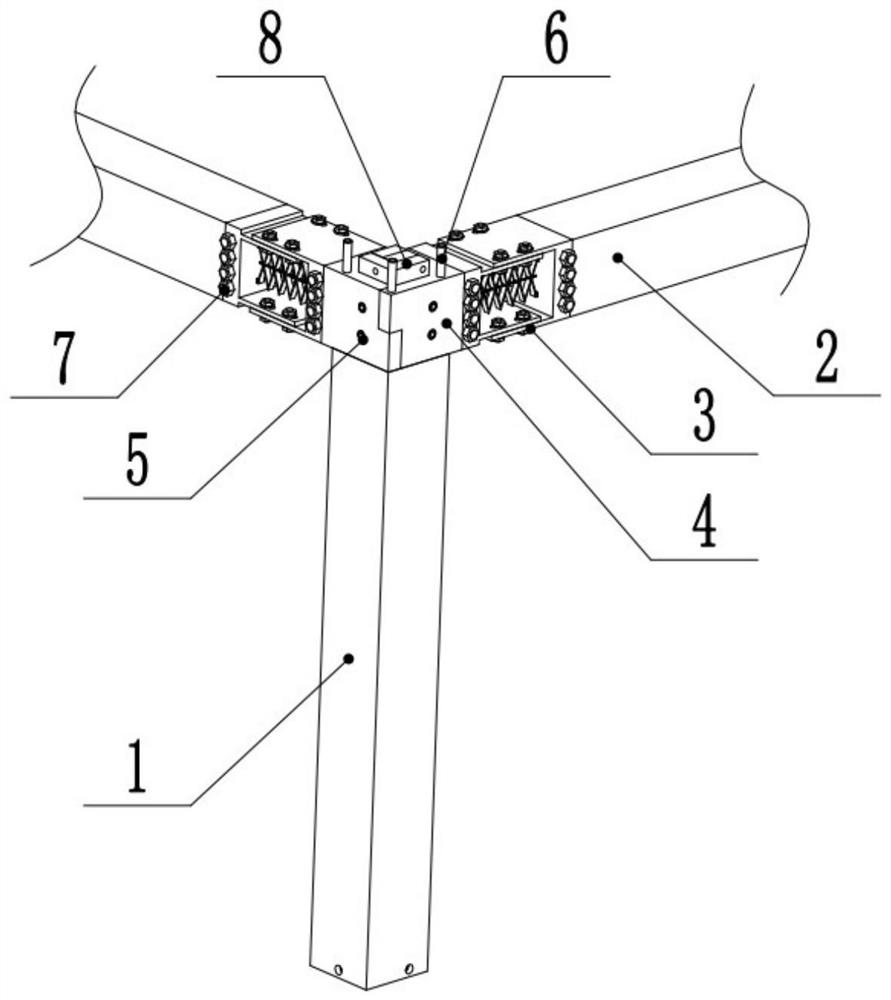

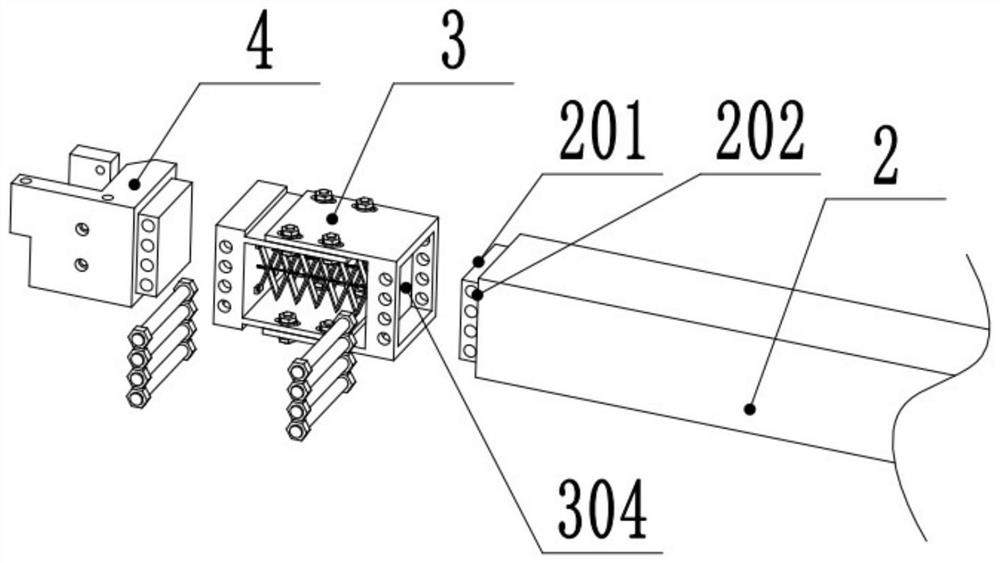

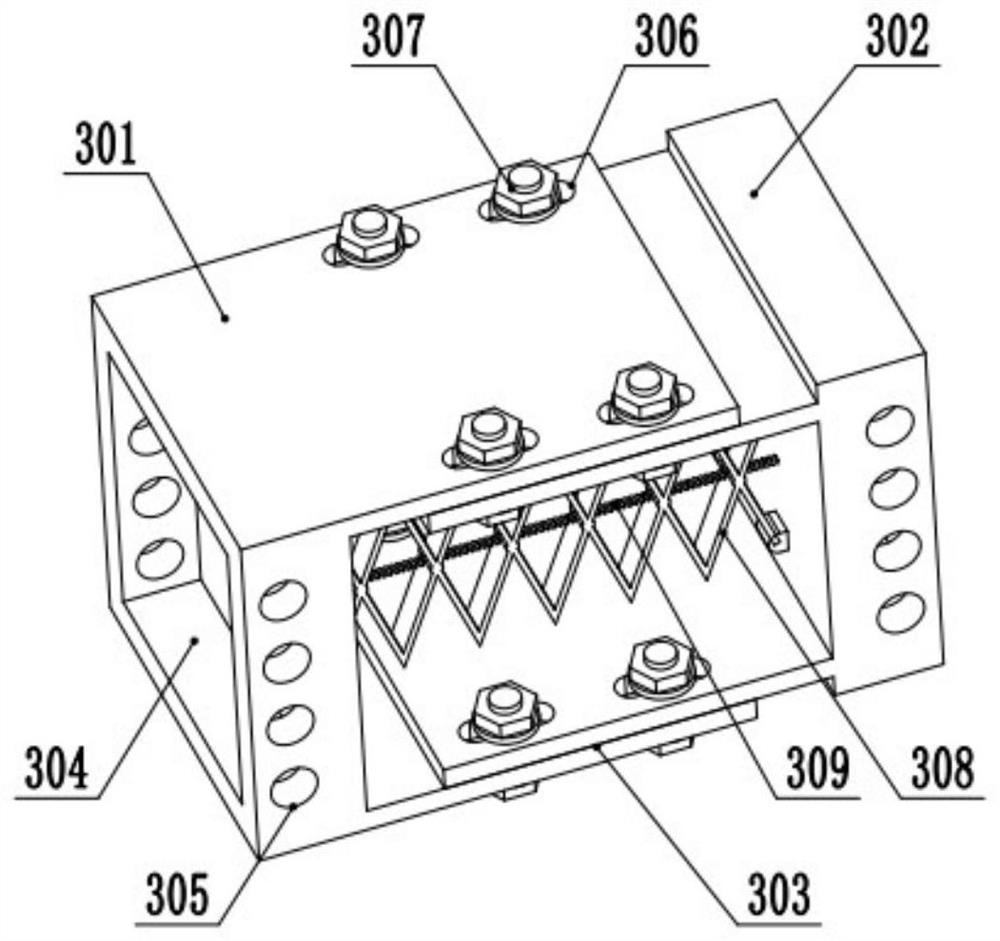

[0046] Such as figure 1 As shown, the prefabricated beam-to-column connection device of the present invention includes a prefabricated column 1, and the top of the prefabricated column 1 is connected with two or three horizontally arranged prefabricated beams 2 through a replaceable joint 4, and the replaceable joint 4 is connected to the prefabricated beam 2 There is a damping device 3 that reduces the lateral vibration between beams and columns. The replaceable joint 4 selects different mortise and tenon structure joints according to the number of prefabricated beams 2 that need to be connected, so that all the prefabricated beams 2 that need to be combined can be connected The replacement joint 4 is spliced to the top of the prefabricated column 1, and a plurality of prefabricated beams 2 are provided with a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com