Pump station unit fault diagnosis method based on noise signal A-weighted analysis

A fault diagnosis and noise signal technology, applied in pump testing, mechanical equipment, machines/engines, etc., can solve problems such as mutual interference of sound sources of pumping station units, inability to accurately characterize fault characteristics, low diagnostic accuracy, etc., to achieve fast and effective The effect of feature learning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

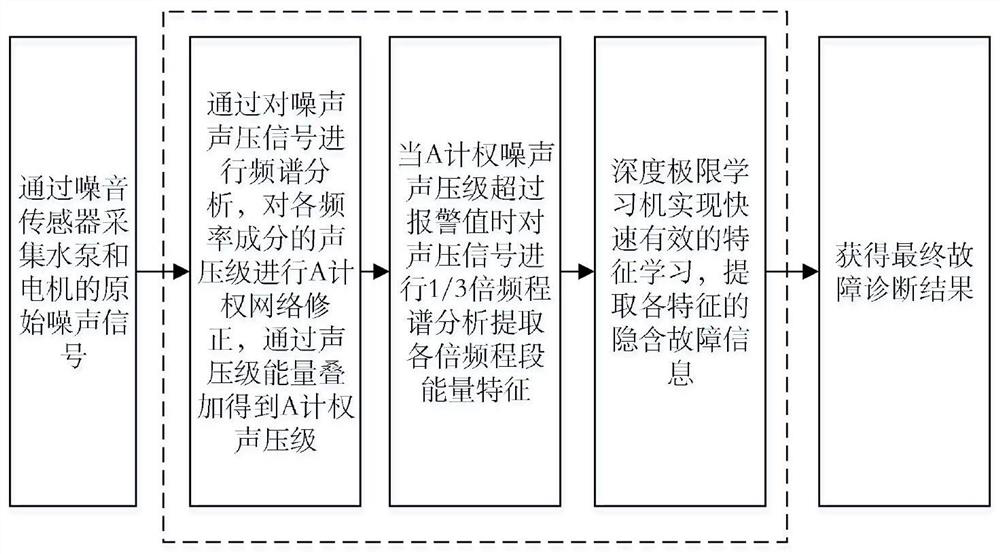

[0076] The fault diagnosis method of the pumping station unit provided by the embodiment of the present invention can be implemented by the following methods:

[0077] Step 1. Install a free-field acoustic sensor near the water pump and motor on the pumping station unit at a distance of 1 meter from the unit equipment to collect the original noise sound pressure signal of the water pump and motor.

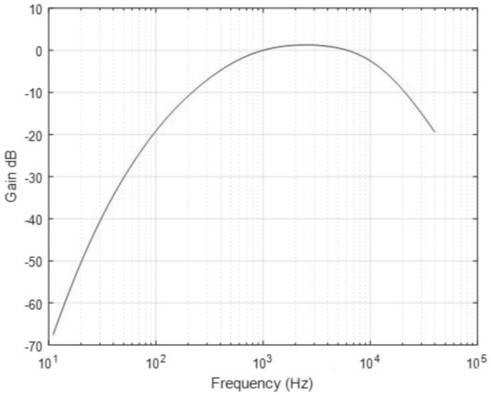

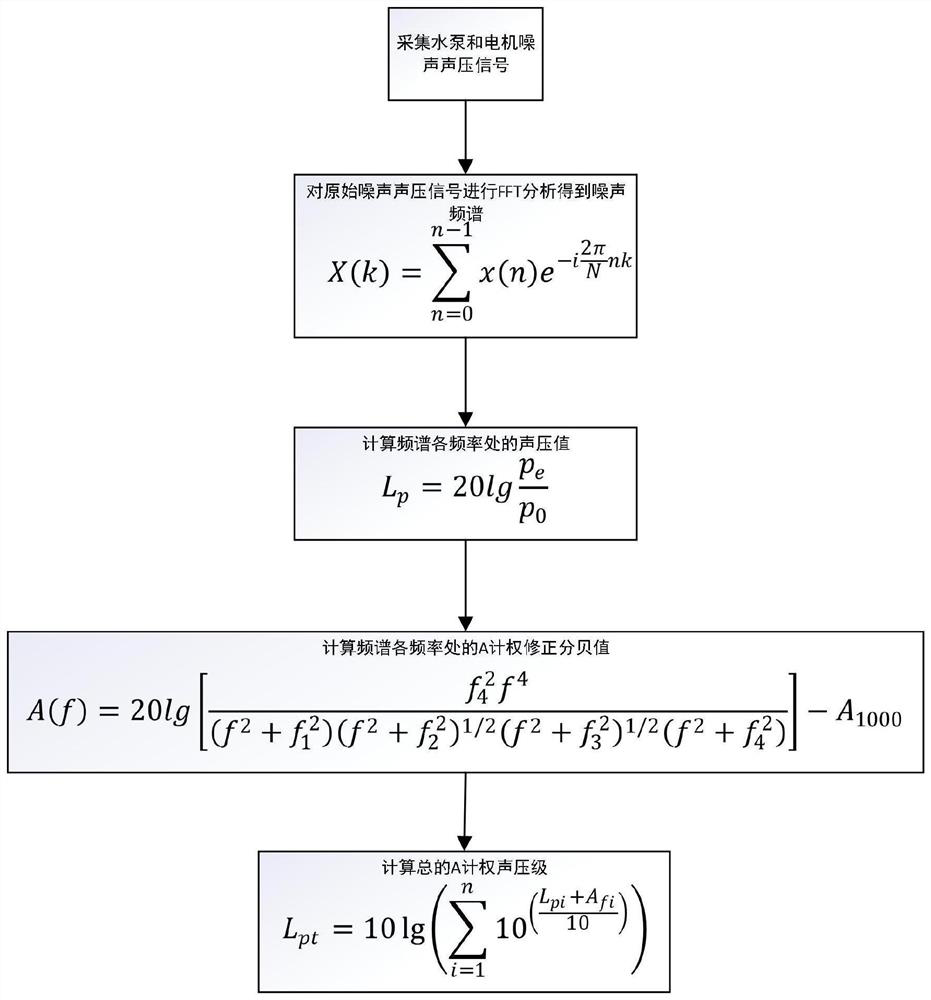

[0078] Step 2. Calculate the A-weighted sound pressure levels of the noise of the water pump and the motor respectively, and use the FFT spectrum decomposition weighted correction method to calculate the A-weighted sound pressure levels.

[0079] Step 3. When the A-weighted sound pressure level alarms, collect fault sample data, that is, pump cavitation, impeller scraping, impeller imbalance, motor rotor imbalance, motor foundation loosening, and motor magnetic pull imbalance. type to add labels to establish a training sample set.

[0080] Step 4, the feature extraction stage, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com