Active regulation and control method for tooth profile deviation of gear involute template

An involute and tooth profile technology, applied in the field of precision machining and testing, can solve the problems of not introducing the precision and machining method of the gear involute model, not meeting, not involving tooth profile shape deviation, etc., and achieving a good market application prospect The effect of promoting value, ensuring consistency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

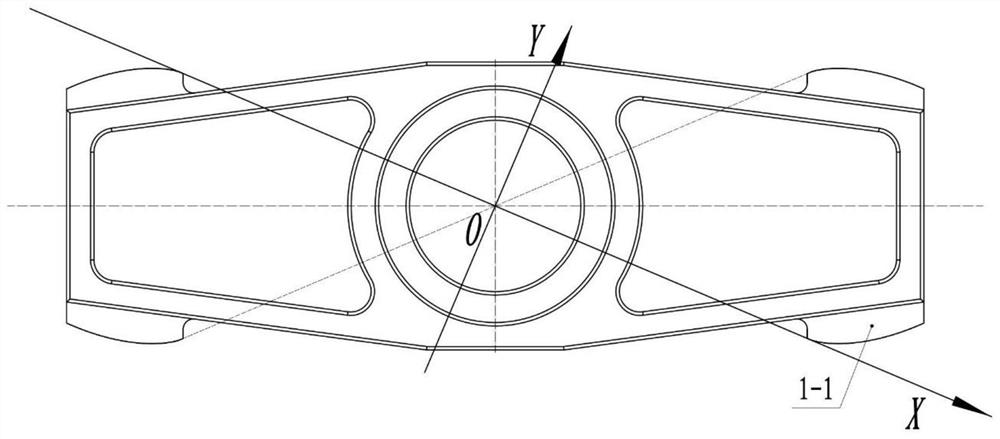

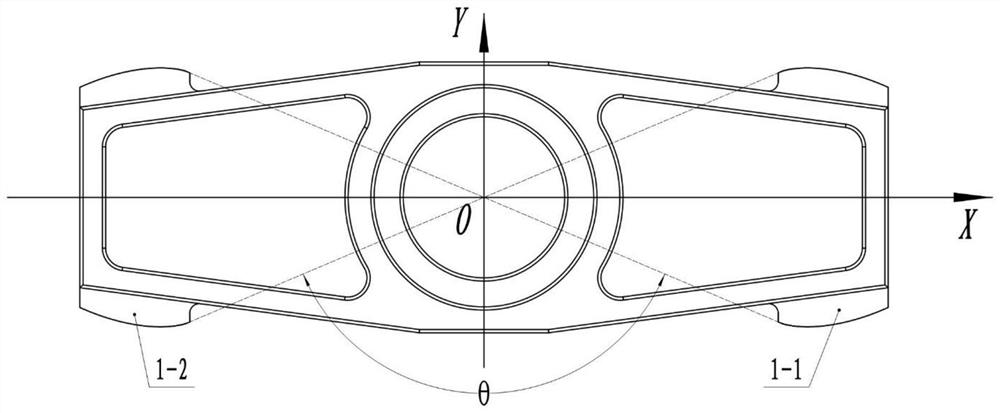

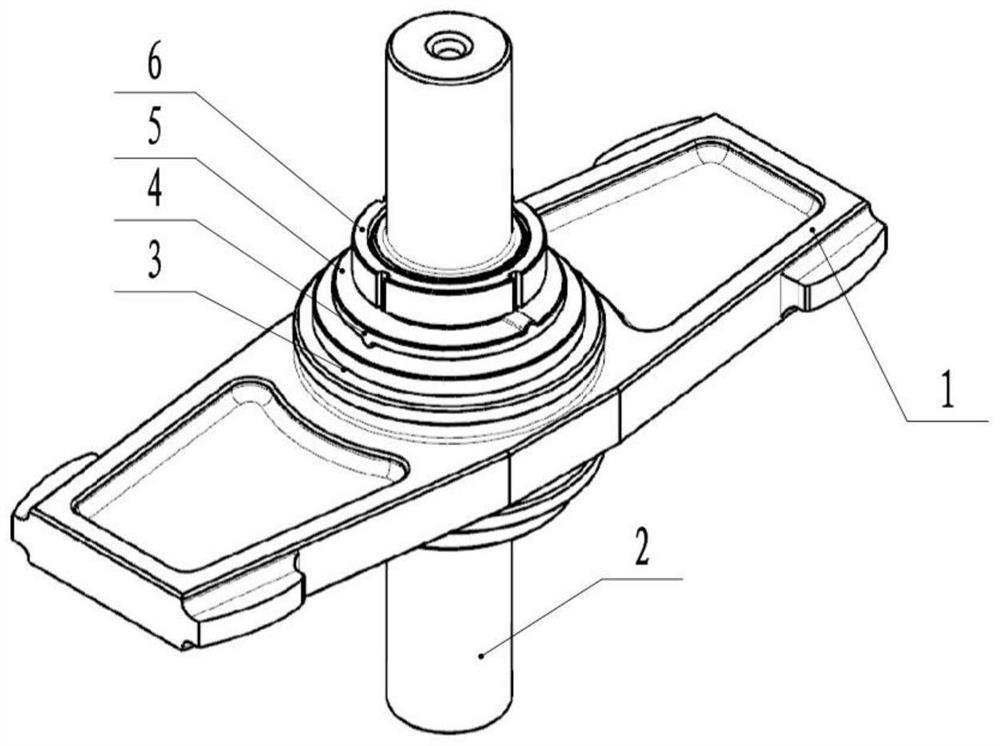

[0038] Take the initial base circle radius r b =100mm, value range 5~65mm, value length L α =60mm gear involute model 1 as an example, set forth the specific implementation of the invention:

[0039] The tooth surface to be regulated is a single tooth surface, that is, when the tooth surface to be regulated is A1-1:

[0040] The first step is to measure the initial tooth profile inclination deviation f of the tooth surface A1-1 to be controlled Hα =3.2μm, initial profile shape deviation f fα = 1.1μm, and separate the initial profile shape deviation f fα The profile crown deviation C in α = 0.3 μm;

[0041] In the second step, take the center of the initial base circle as the origin, and take the line connecting the initial base circle center and the involute at the base circle as the X-axis to establish a right-handed coordinate system, and use the installation eccentricity e of the gear involute template 1 along the Y-axis direction y Control tooth profile shape deviation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com