Portable civil rapid and safe sugarcane cutting-off equipment

A safe cutting and convenient technology, applied in application, metal processing, peeling of vegetables or fruits, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, etc., and achieve the effect of improving work efficiency, improving efficiency and saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

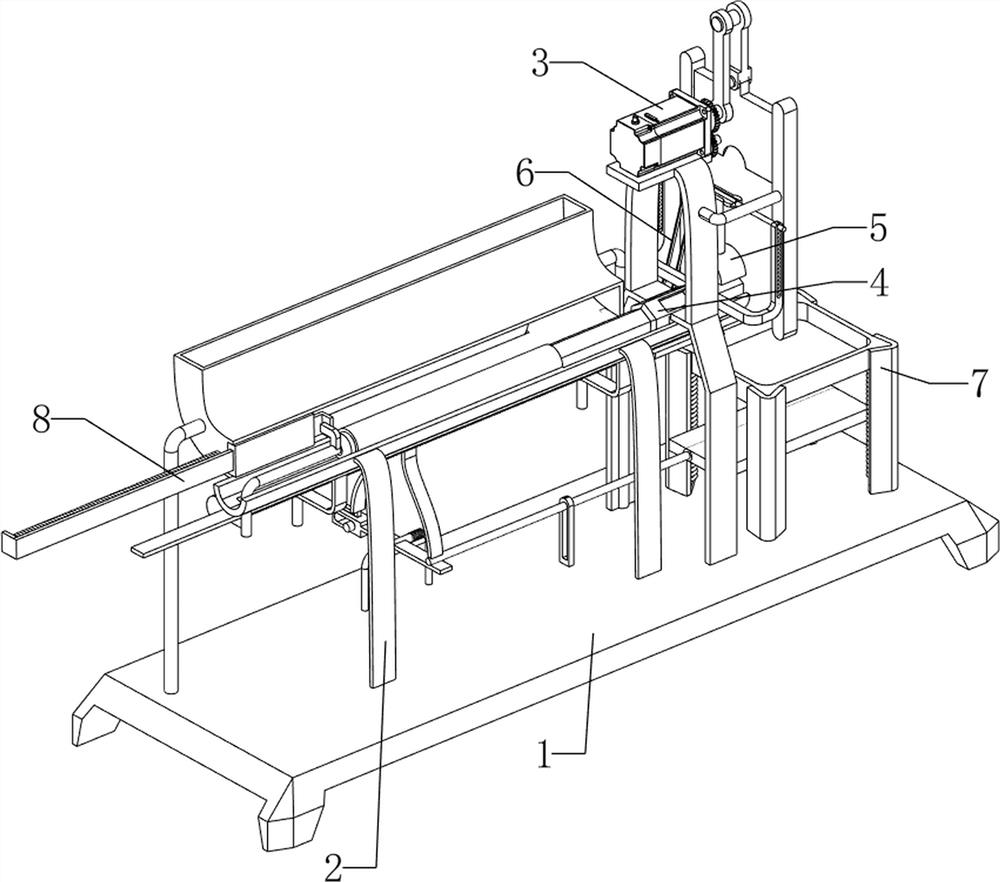

[0034] A portable civil sugarcane fast and safe cutting equipment, such as figure 1 and figure 2 As shown, it includes a bottom plate 1, a blanking mechanism 2 and a cutting mechanism 3. The top left side of the bottom plate 1 is connected with the blanking mechanism 2, and the right side of the blanking mechanism 2 is connected with the cutting mechanism 3.

[0035] The blanking mechanism 2 includes a support plate 20, the first slide rail 21, a support rod 22 and a blanking frame 23. The left and right sides of the front portion of the bottom plate 1 are connected with the support plate 20, and the support plates 20 tops on both sides are connected with a The first slide rail 21, the left and right sides of the rear portion of the base plate 1 are connected with support rods 22, and the upper parts of the support rods 22 on both sides are connected with a blanking frame 23, and the outlet of the blanking frame 23 is located directly above the first slide rail 21.

[0036] ...

Embodiment 2

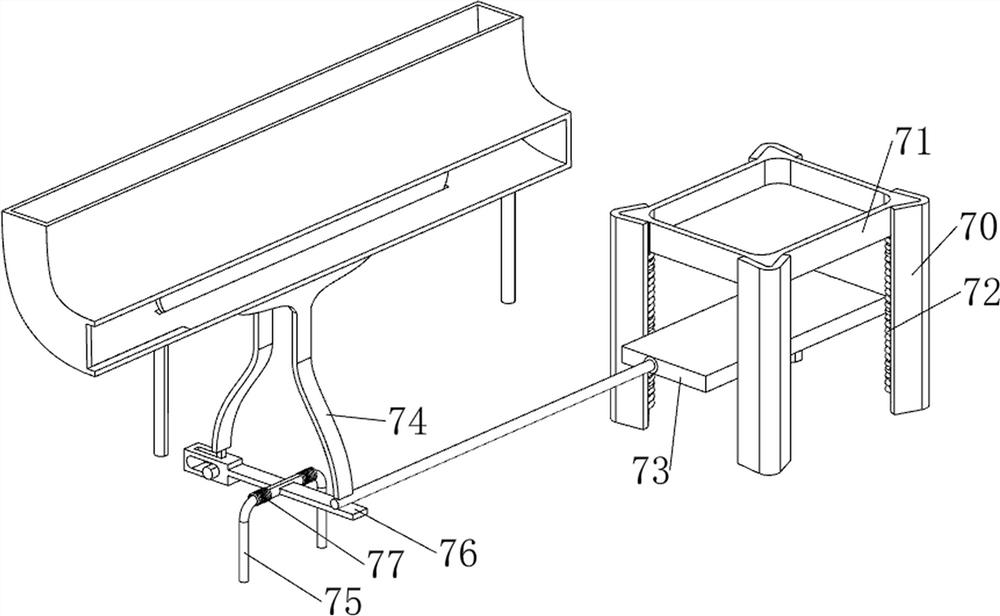

[0039] On the basis of Example 1, such as image 3 As shown, a peeling knife 4 is also included, and the upper right side of the first slide rail 21 is connected with a peeling knife 4 .

[0040] When artificially promoting sugarcane to move to the right, sugarcane contacts with peeling knife 4 and sugarcane skin is separated, thus does not need artificially peeling sugarcane when sugarcane is eaten manually.

[0041] like image 3 and Figure 4 As shown, it also includes a pressing mechanism 5, and the pressing mechanism 5 includes a third slide rail 50, a pressing bar 51, a first fixed block 52, a first spring 53 and a second spring 54, and the upper right side of the peeling knife 4 The third slide rail 50 is connected, and the inner side of the third slide rail 50 is slidably connected with a pressure rod 51, and the lower side of the middle part of the pressure rod 51 is connected with a first fixing block 52, and a sleeve is set between the pressure rod 51 and the firs...

Embodiment 3

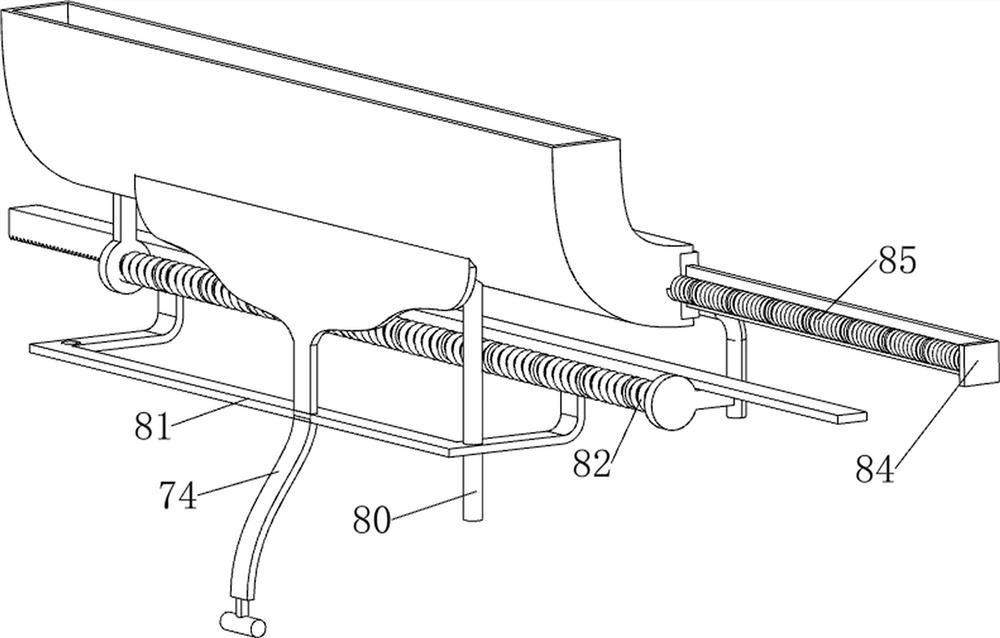

[0044] On the basis of Example 2, such as Figure 5Shown, also comprise pusher mechanism 6, pusher mechanism 6 comprises missing gear 60, the first full gear 61, rotating shaft 62, belt 63, bevel gear set 64, bearing seat 65, the second full gear 66 and rack Plate 67, the output shaft of servo motor 31 is connected with the missing gear 60, the upper right side of the support frame 30 is connected with the first full gear 61, the first full gear 61 meshes with the missing gear 60, and the lower part of the rear side of the support frame 30 is rotatably connected There is a rotating shaft 62, a belt 63 is connected between the rotating shaft 62 and the first full gear 61, the lower part of the rear side of the support frame 30 is connected with a bearing seat 65, and the right side of the bearing seat 65 is rotatably connected with a second full gear 66, and the second full gear A bevel gear set 64 is connected between 66 and the rotating shaft 62 , and a rack plate 67 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com