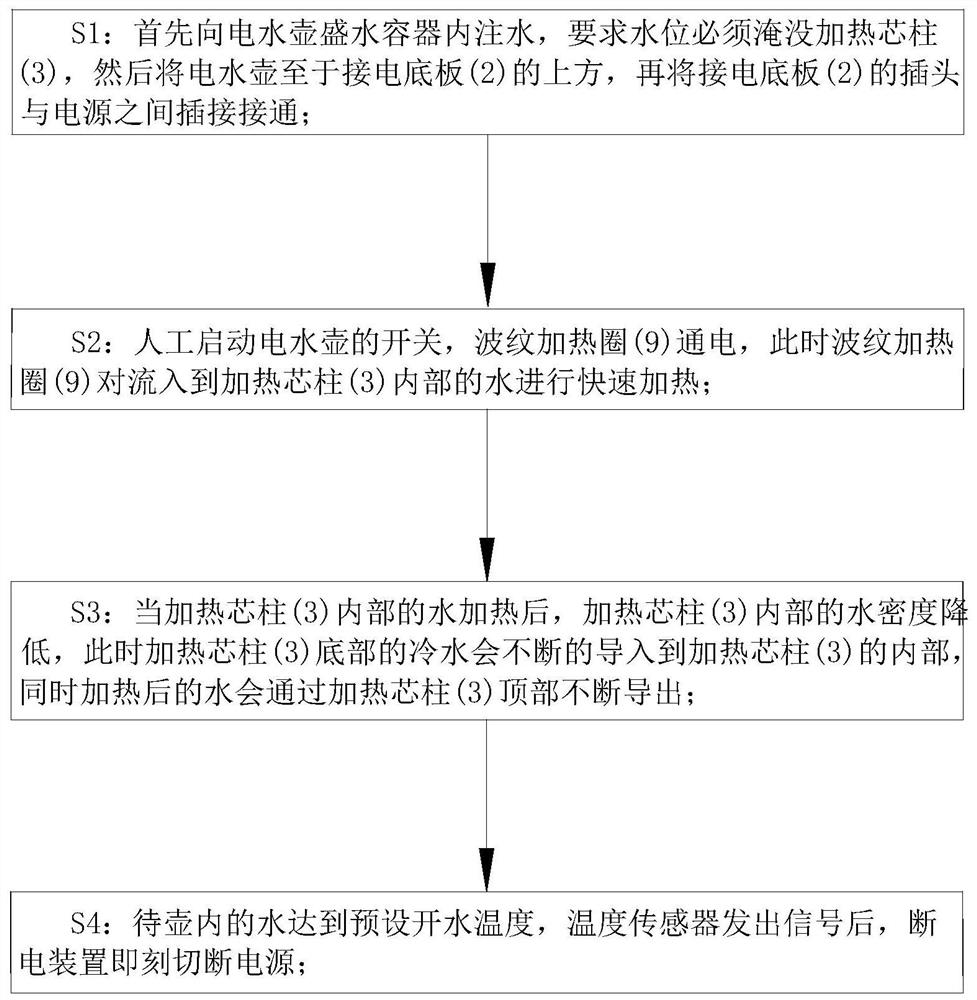

Electric kettle using method

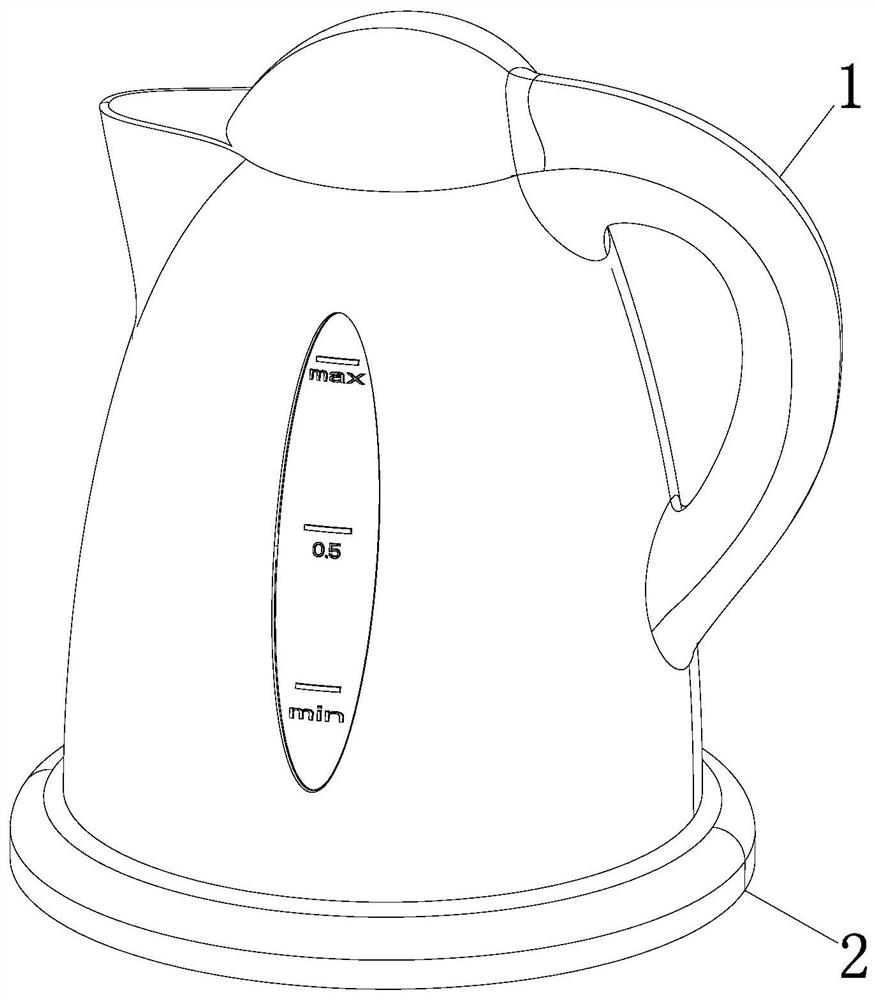

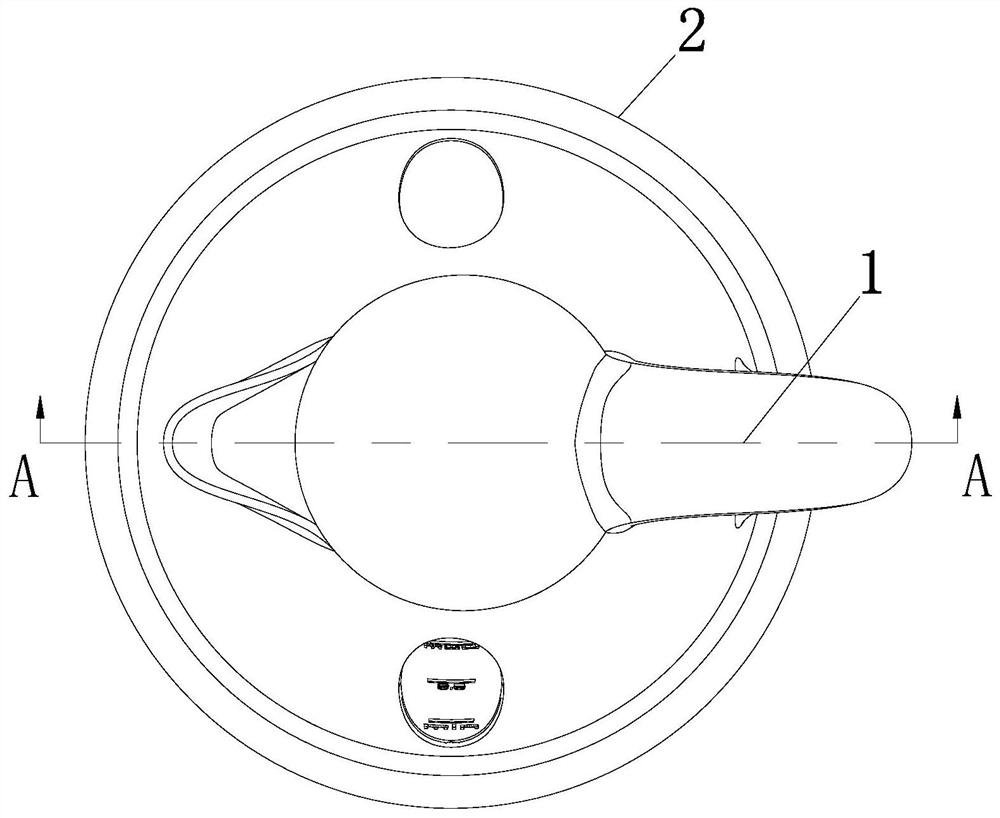

An electric kettle and kettle technology, applied in applications, kitchen utensils, household appliances, etc., can solve the problems of electric kettle vibration, large vibration noise, affecting experience, etc., to facilitate flow, increase the volume of grooves, and improve heating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] As an embodiment of the present invention, the surface of the elastic sheet 14 is provided with a fixing hole; the inside of the fixing hole is provided with a push rod 15; the bottom surface of the elastic sheet 14 is fixedly connected with a support block 16; the support block 16 is fixedly connected with a first liquid bag 17 on one side of the corresponding push rod 15; the surface of the support column 8 is fixed with a uniformly arranged second liquid bag 18, and the second liquid bag 18 is connected with the corresponding first liquid bag. The first liquid bag 17 communicates with each other; when working, by setting the first liquid bag 17 and the second liquid bag 18, through the deformation of the elastic sheet 14, the elastic sheet 14 will drive the ejector rod 15 to move, and the ejector rod 15 will correspond to the corresponding first liquid bag. A liquid bag 17 is squeezed, so that the liquid inside the first liquid bag 17 enters into the corresponding sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com