a vacuum cleaner

A technology for vacuum cleaners and suction tubes, which is applied in the direction of vacuum cleaners, suction filters, suction nozzles, etc. It can solve the problems of backward air force layout, large wind resistance, and low filtration area, so as to reduce the filtration wind speed and aerodynamic resistance, prolong the service life, and improve The effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

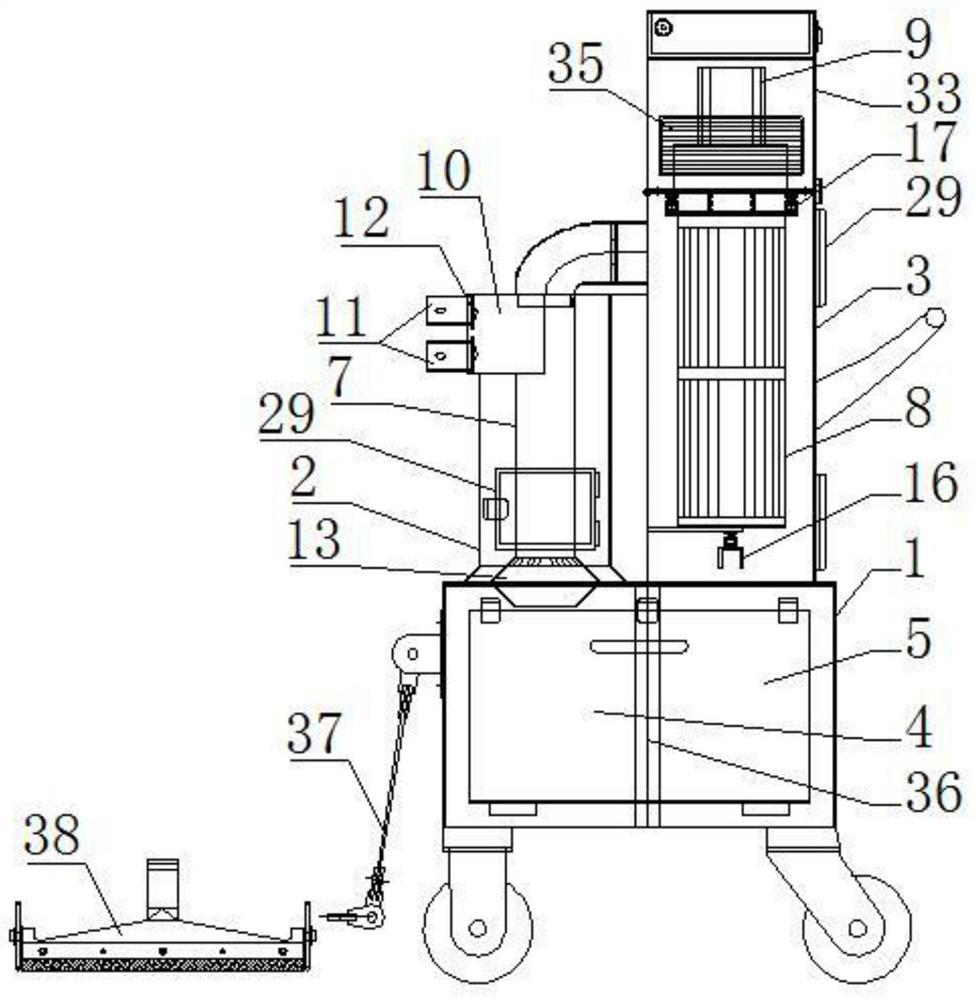

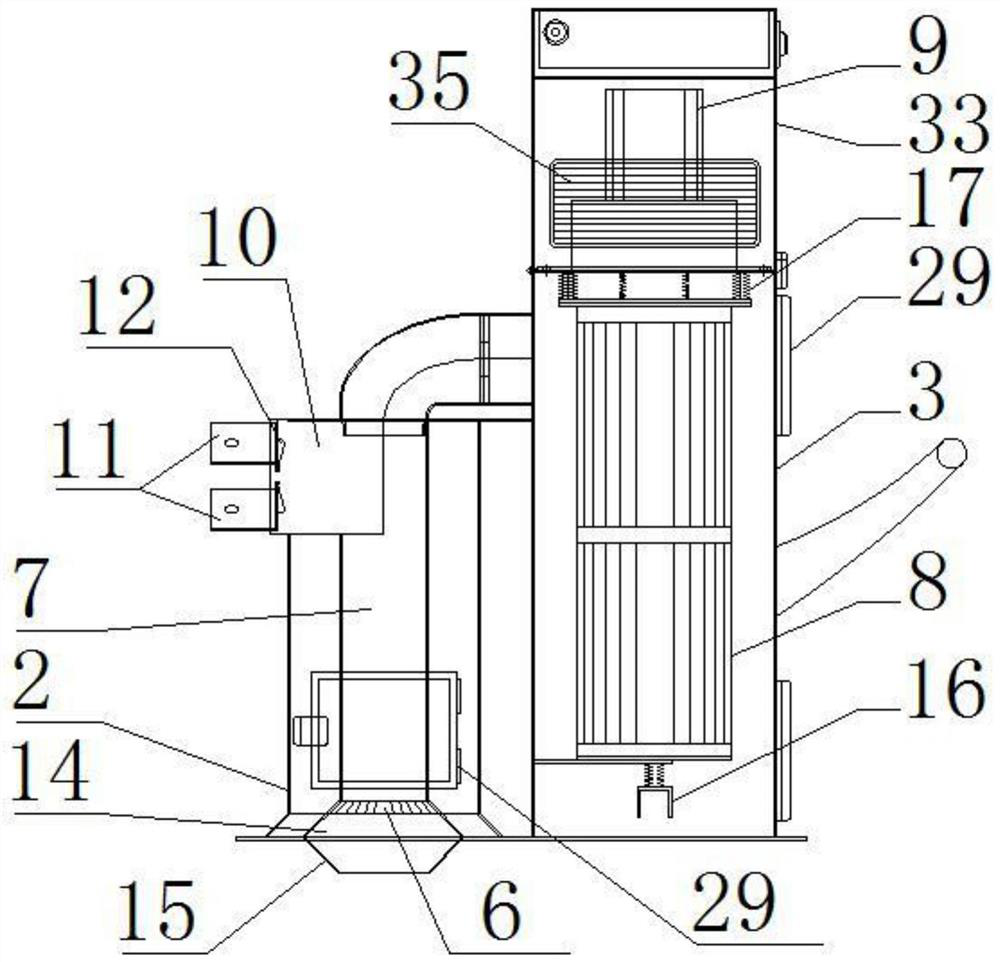

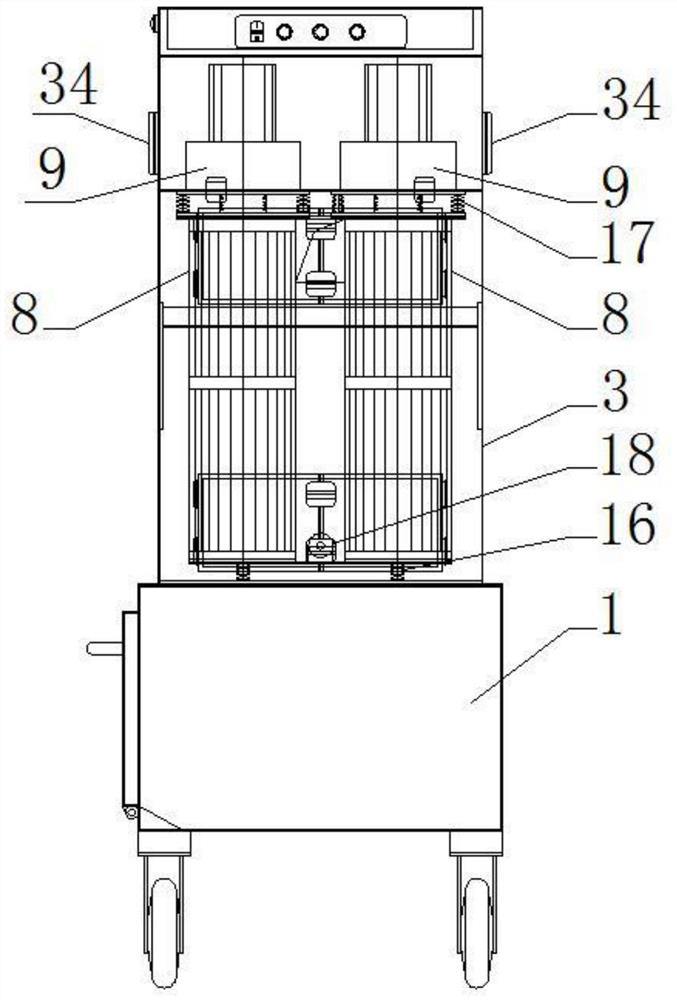

[0023] Reference Figure 1- Figure 9 , a vacuum cleaner, comprising ash chamber 1 and the outer cylinder 2 disposed above the ash chamber 1, purification chamber 3, the outer cylinder 2 and the first chamber 4 of the ash chamber 1 are connected, the purification chamber 3 is connected with the second chamber 5 of the ash chamber 1, the outer cylinder 2 is installed with a suction component, the outer cylinder 2 is installed with the lower end of the inner cylinder 6 inner cylinder 7, the upper end of the inner cylinder 7 is connected with the purification chamber 3, the suction components are in turn connected with the inner chamber of the outer cylinder 2, the air hole 6, the inner cavity of the inner cylinder 7, the inner cavity of the purification chamber 3 is connected, and the filter 8 is installed in the purification chamber 3 The air purified by filter 8 is discharged through the fan 9, and the filter 8 is preferably a filter cartridge, using a tiny breathable tissue formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com