Windproof polyester fabric coating agent processing device

A technology of polyester fabric and processing device, which is applied in grain treatment, water heater, fluid heater, etc., can solve the problems of low decomposition efficiency of raw materials, inability to stir and break raw materials, and reduce the preparation efficiency of coating agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

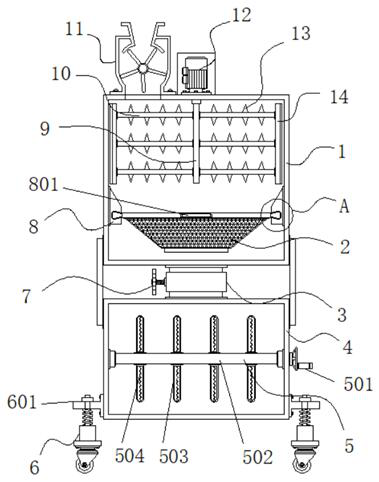

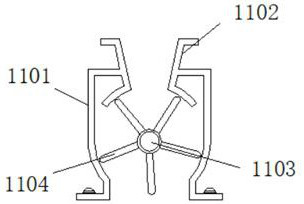

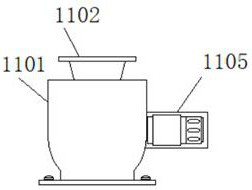

[0035] Example 1: See Figure 1-6 , a windproof polyester fabric coating agent processing device, comprising a decomposition bin 1 and a filter screen 2, the filter screen 2 is arranged inside the decomposition bin 1 at a position close to the bottom end, and the bottom end of the decomposition bin 1 is fixedly connected with a preparation bin 4, which is decomposed A connecting pipe 3 is fixedly connected between the middle position of the bottom end of the bin 1 and the middle position of the top end of the preparation bin 4, a valve 7 is arranged on one side of the connecting pipe 3, and a uniform feeding mechanism 11 is arranged on the top side of the decomposition bin 1 The two sides of the filter screen 2 are provided with structures 8 for easy cleaning, the interior of the preparation chamber 4 is provided with a uniform material heating mechanism 5, the four corners of the bottom of the preparation chamber 4 are respectively provided with structures 6 for easy movement,...

Embodiment 2

[0039] Embodiment 2: The uniform material heating mechanism 5 is composed of a rotating handle 501, a movable shaft 502, a heating cylinder 503 and an electric heating wire 504. The movable shaft 502 is movably connected to the inside of the preparation chamber 4, and one side of the movable shaft 502 is fixedly connected with a rotating shaft. 501, the outside of the movable shaft 502 is fixedly connected with a heating cylinder 503, and the inside of the heating cylinder 503 is fixedly connected with a heating wire 504, and the type of the heating wire 504 can be ocr21al6nib;

[0040] The outer side of the movable shaft 502 is fixedly connected with a shaft sleeve, and one side of the movable shaft 502 penetrates through the shaft sleeve to the outer side of the preparation chamber 4;

[0041] Specifically, such as figure 1 As shown, when in use, if the temperature is low, the heating wire 504 is energized, and the heating wire 504 makes the heating cylinder 503 have a certa...

Embodiment 3

[0042] Embodiment 3: The easy-to-move structure 6 is composed of a support plate 601, a support column 602, a fixed caster 603, a connecting seat 604, a spring 605 and a limit block 606, and the support plate 601 is respectively fixedly connected to the two ends of the bottom of the preparation chamber 4 , the inside of the support plate 601 runs through a support column 602, the bottom end of the support column 602 is fixedly connected with a connection seat 604, the bottom end of the connection seat 604 is fixedly connected with a fixed caster 603, the outside of the support column 602 is provided with a spring 605, the support column The top of the outside of 602 is fixedly connected to the limit block 606;

[0043] The spring 605 is sleeved on the outside of the support column 602, and the top end and the bottom end of the spring 605 are respectively fixedly connected with the support plate 601 and the connecting seat 604;

[0044] Specifically, such as figure 1 and Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com