Sand screening equipment for road and bridge construction

A technology for bridge construction and screening equipment, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of difficult sand screening, delayed construction time, and reduced sand screening efficiency, and achieves the goal of improving screening efficiency and work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

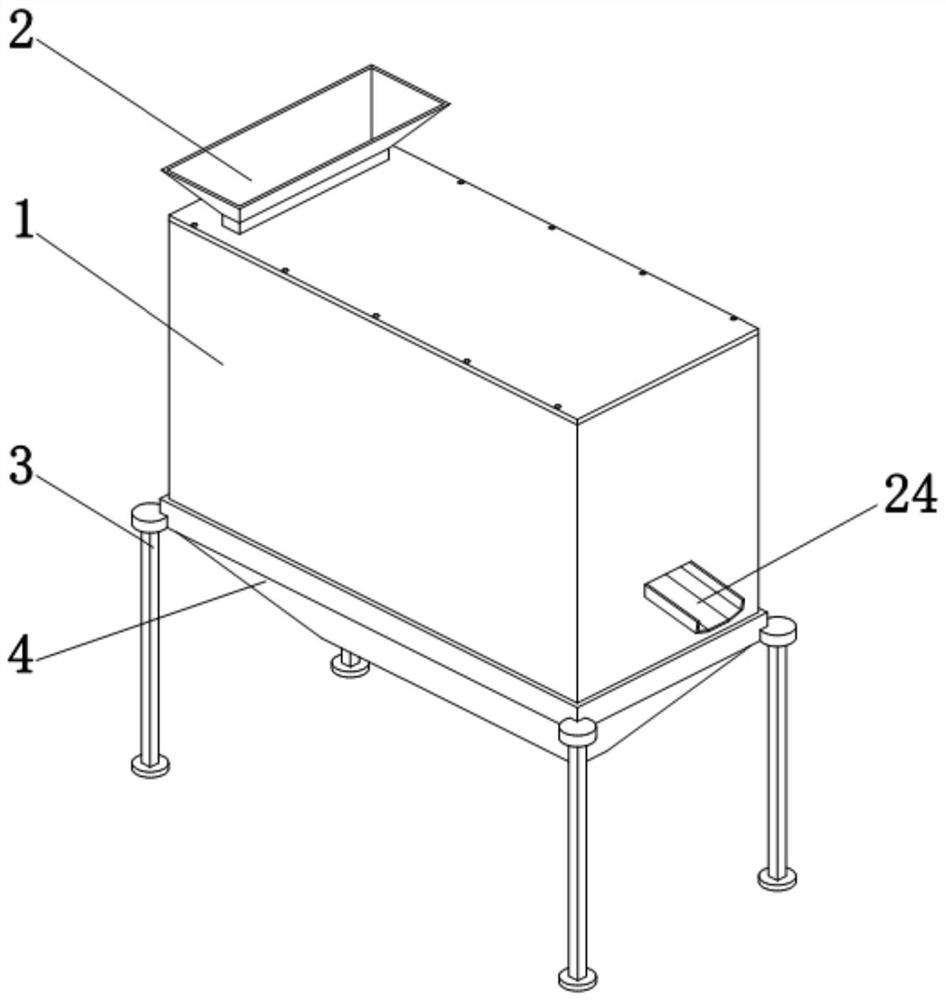

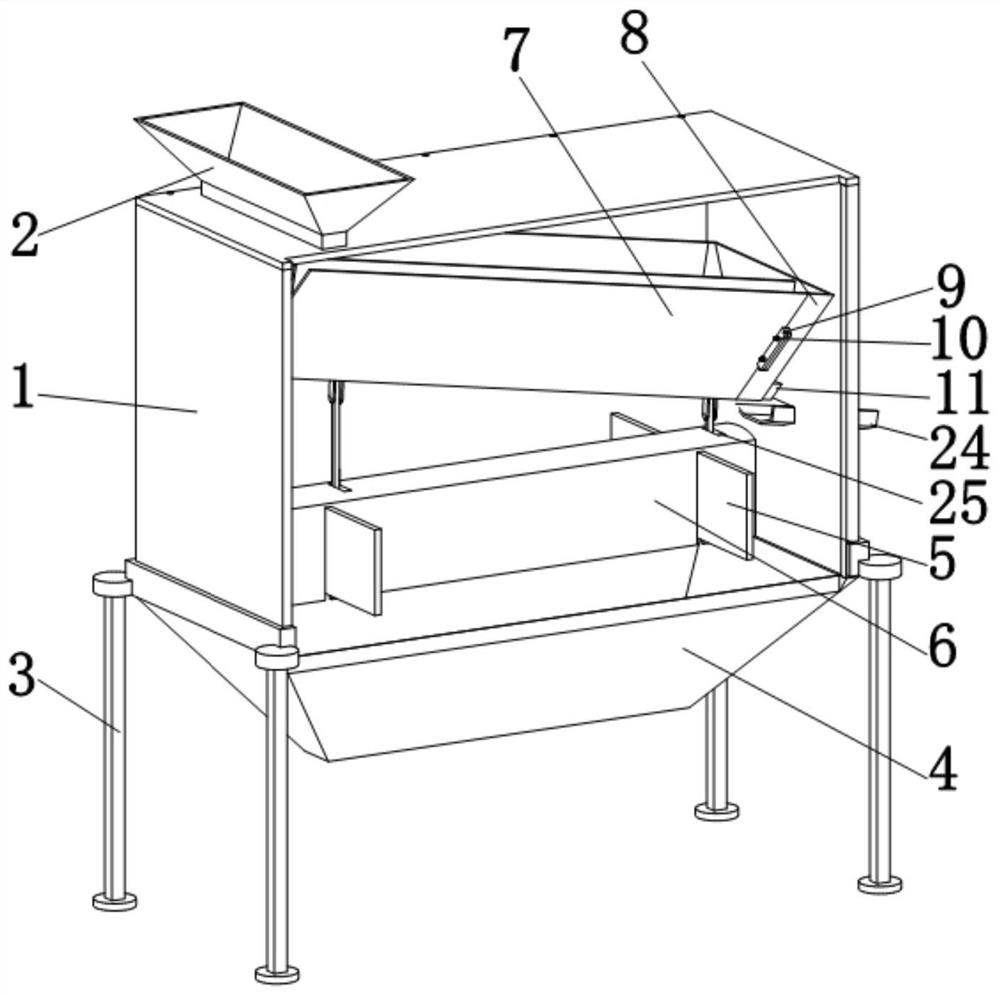

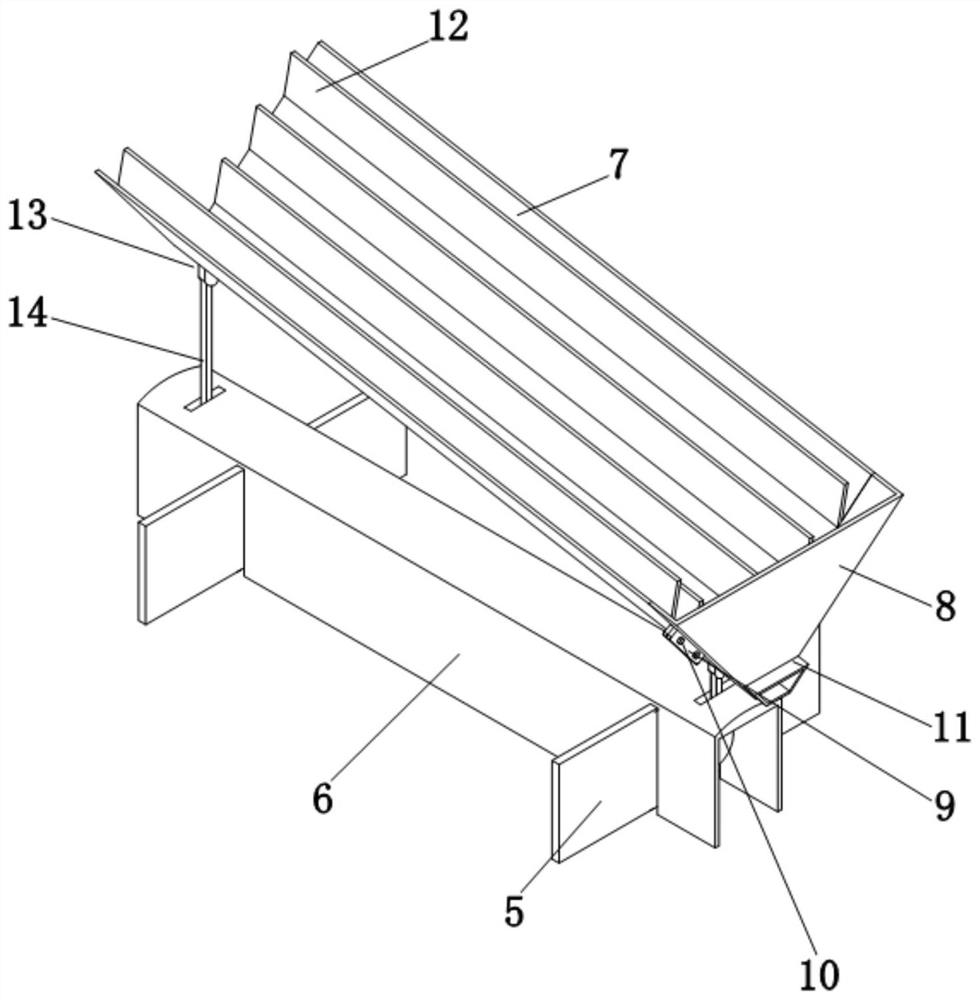

[0032] Such as Figure 1 to Figure 7As shown, the present invention provides a sand screening device for road and bridge construction, comprising a device housing 1, the top of the device housing 1 is provided with an upper funnel 2, and the upper funnel 2 is mainly used for charging, and the outer surface of the device housing 1 is evenly arrayed with A plurality of supporting legs 3, the bottom of the supporting legs 3 is provided with a buffer gasket, the bottom of the device shell 1 is provided with a bottom drain 4, and the bottom of the bottom drain 4 is provided with a bottom drain 23, and the sand after screening is arranged along the bottom drain 23. The outflow device is generally conveyed through a belt slideway. The inner wall of the device housing 1 is provided with a barrier cover 6. The top of the barrier cover 6 is an upwardly protruding arc, so that the sand falling on it will slide down along the arc, and The existence of the barrier cover 6 isolates the tran...

no. 2 example

[0036] Based on the sand screening equipment for road and bridge construction provided in the first embodiment, although the screening effect can be significantly improved by partitioning the top of the trapezoidal sieve plate 7 to avoid accumulation in actual use, the partition plate 12 vertical Vertical placement will cause part of the sand to accumulate in the sub-area and it is difficult to sieve only by vibration, resulting in blockage of the sieve holes, and this sieving method will inevitably have a very significant problem, and the trapezoidal sieve plate 7 will be in the process of rising. However, during the descending process of the trapezoidal sieve plate 7, the action direction of the trapezoidal sieve plate 7 is downward at this time, and the falling speed of the sand is not as fast as that of the trapezoidal sieve plate 7 only by its own weight. The speed is fast, so it does not have the screening function or the screening effect is very poor during the descent p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com