Machining device for inner lifting lug specially-shaped cover

A technology of processing device and special-shaped cover, which is applied in the field of forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

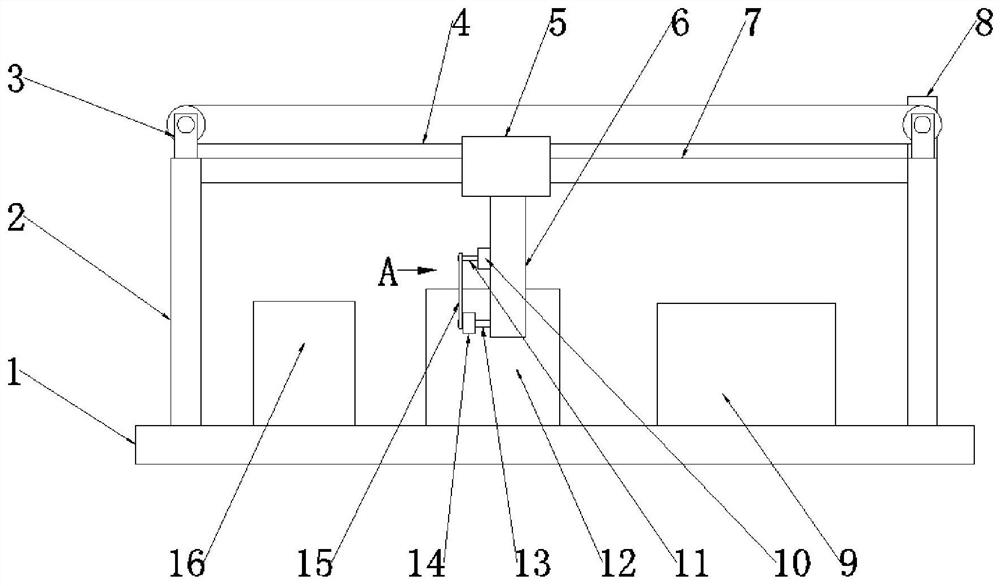

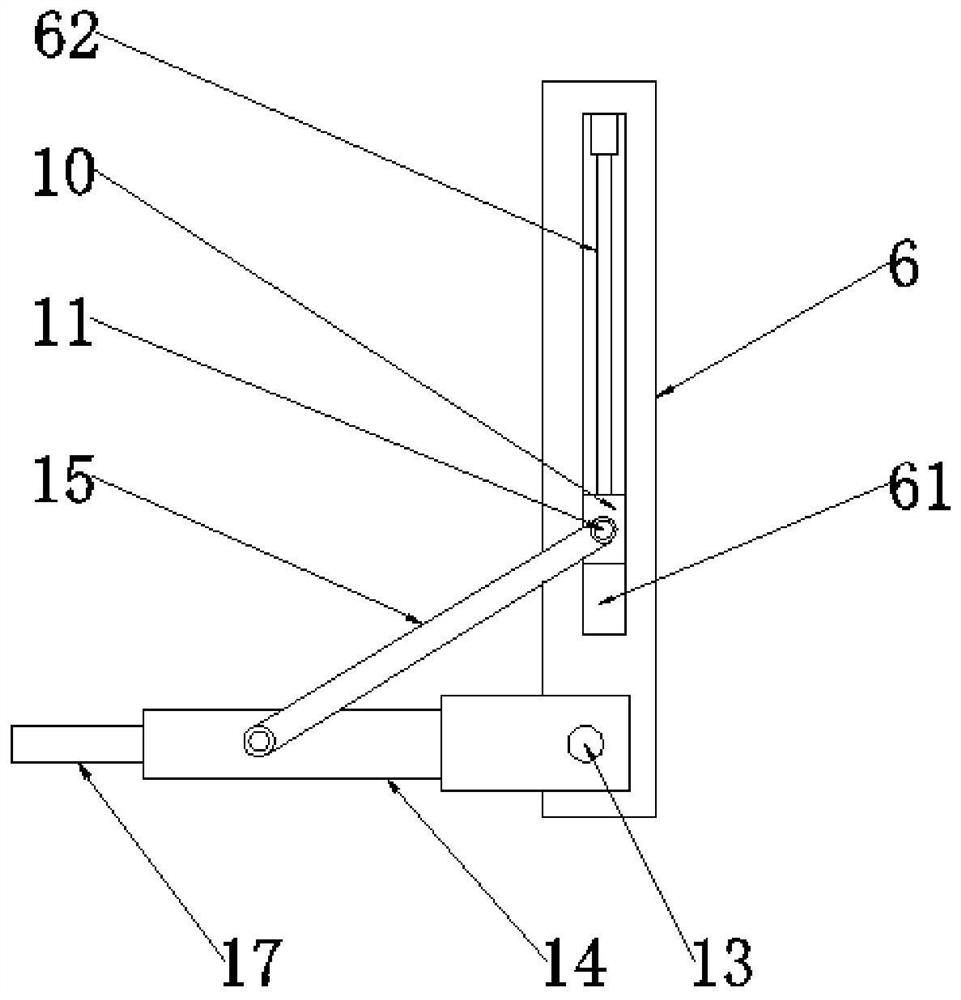

[0019] Embodiment 1 is basically as attached figure 1 and figure 2 Shown: a processing device for special-shaped covers with inner lugs, including a base 1, on which an electric furnace 16, a punching machine 12, and a ring rolling machine 9 are arranged in sequence, and a support frame 2 is also provided on the base 1, and on the support frame 2 A cross bar 7 is provided, and a slide block 5 is slidably connected to the cross bar 7. A drive mechanism for driving the slide block 5 to slide on the cross bar 7 is provided on the support frame 2. The drive mechanism includes two coils arranged on the support frame 2 Wire wheel 3 and the stay cord 4 that is wound on the reel 3, the two ends of stay cord 4 are fixedly connected with the left and right sides of slide block 5 respectively, and support frame 2 is provided with the motor 8 that drives the reel 3 to rotate , the slider 5 is fixed with a connecting rod 6, the bottom end of the connecting rod 6 is fixed with a rotating ...

Embodiment 2

[0021] Embodiment 2, on the basis of Embodiment 1, the following content is added: the cross bar 7 is provided with a T-shaped chute, and the slider 5 slides in the chute. Through such arrangement, the slider 5 is accommodated in the chute, which increases the stability when sliding.

Embodiment 3

[0022] Embodiment 3 differs from Embodiment 2 in that: the sliding block 5 is provided with a rectangular through hole, and the sliding block 5 is slidably socketed on the cross bar 7 through the through hole. Through such arrangement, the cross bar 7 is accommodated in the slider 5, which increases the stability during sliding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com