PVC pipe cutting device based on rotary separation

A PVC pipe and cutting device technology, applied in metal processing and other directions, can solve the problems of affecting the cutting speed of pipes, reducing the production speed of pipes, and slow cutting speed, so as to avoid friction, facilitate operation, and speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

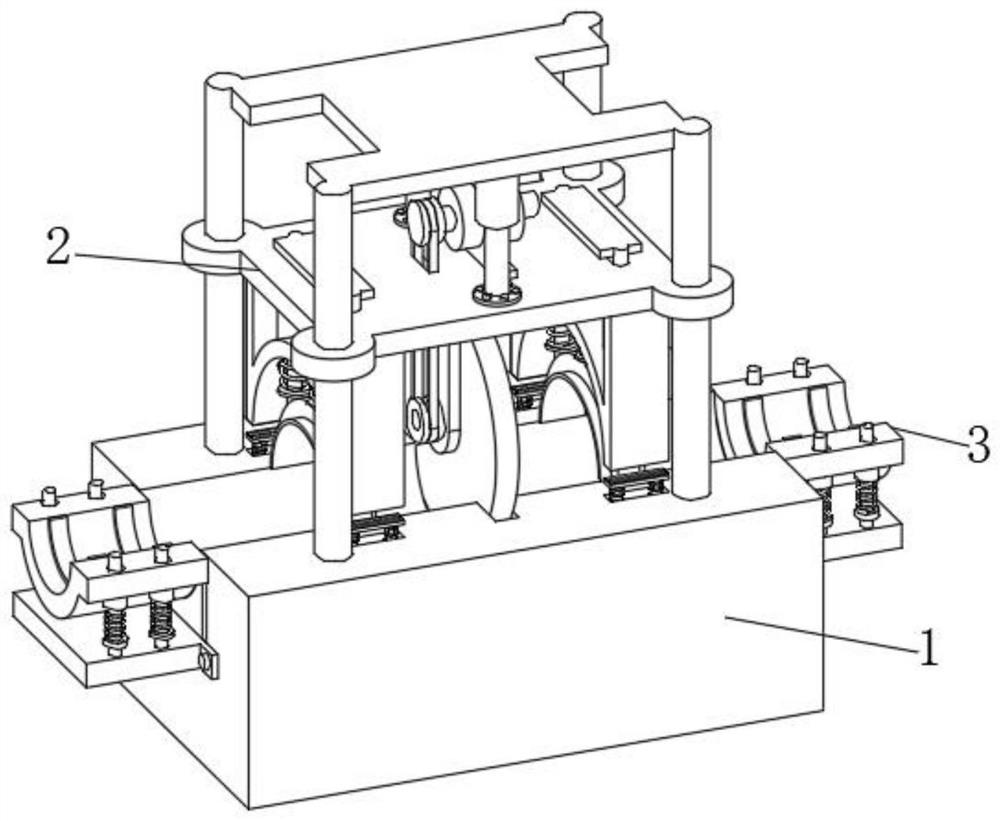

[0046] see Figure 1-Figure 10 As shown, a PVC pipe cutting device based on rotary separation is provided, including a cutting frame 1, a cutting positioning device 2 is provided inside the cutting frame 1, and auxiliary positioning devices 3 are provided on the left and right sides of the cutting frame 1;

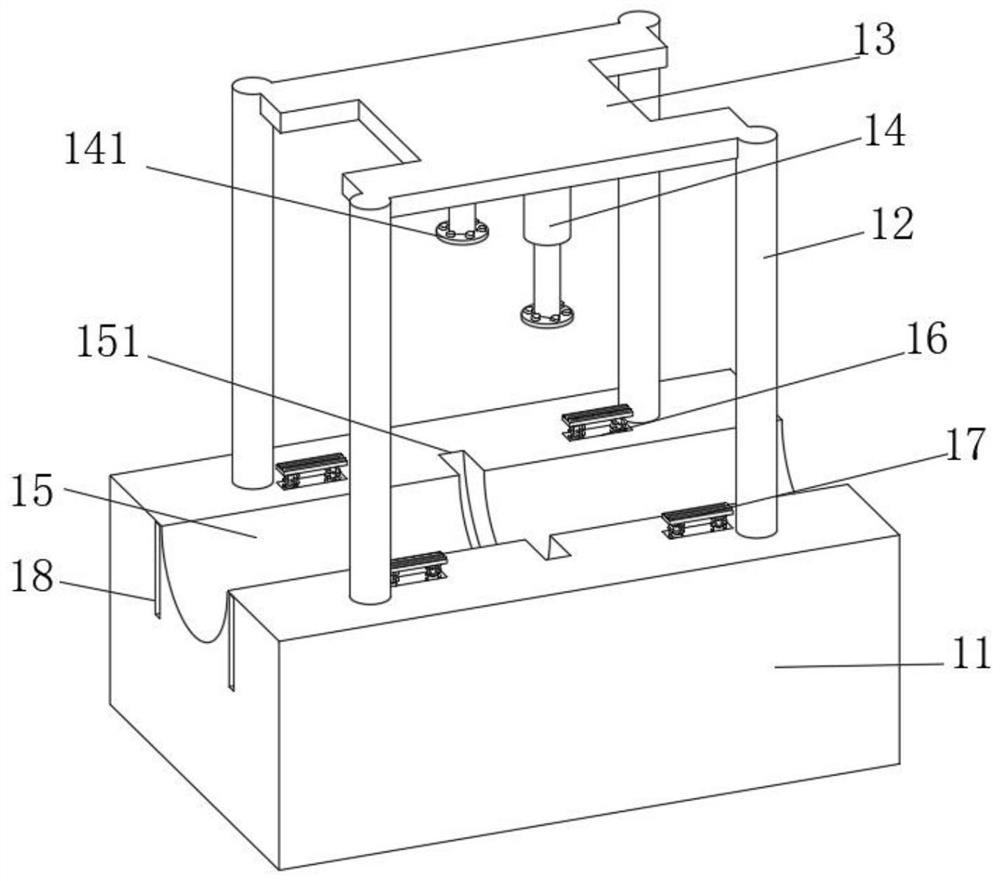

[0047] The cutting frame 1 includes a device base 11, the four corners of the upper surface of the device base 11 are fixedly connected with support columns 12, and the tops of a plurality of support columns 12 are fixedly connected with a support top plate 13, and the bottom of the support top plate 13 is close to the middle position. Symmetrical fixed connection with a straight cylinder 14, the upper surface of the device base 11 is provided with a pipe placement groove 15 that runs through the front and rear sides of the device base 11, and there are side chutes symmetrically opened on the side walls of the device base 11 at both ends of the pipe placement groove 15 18....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com