Rail transit power transmission rail insulation support

A rail transit and insulating support technology, applied in the field of rail transit, can solve the problems of inconvenient assembly and disassembly of insulating supports, and achieve the effects of convenient assembly and disassembly, convenient manual operation, and maintenance of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

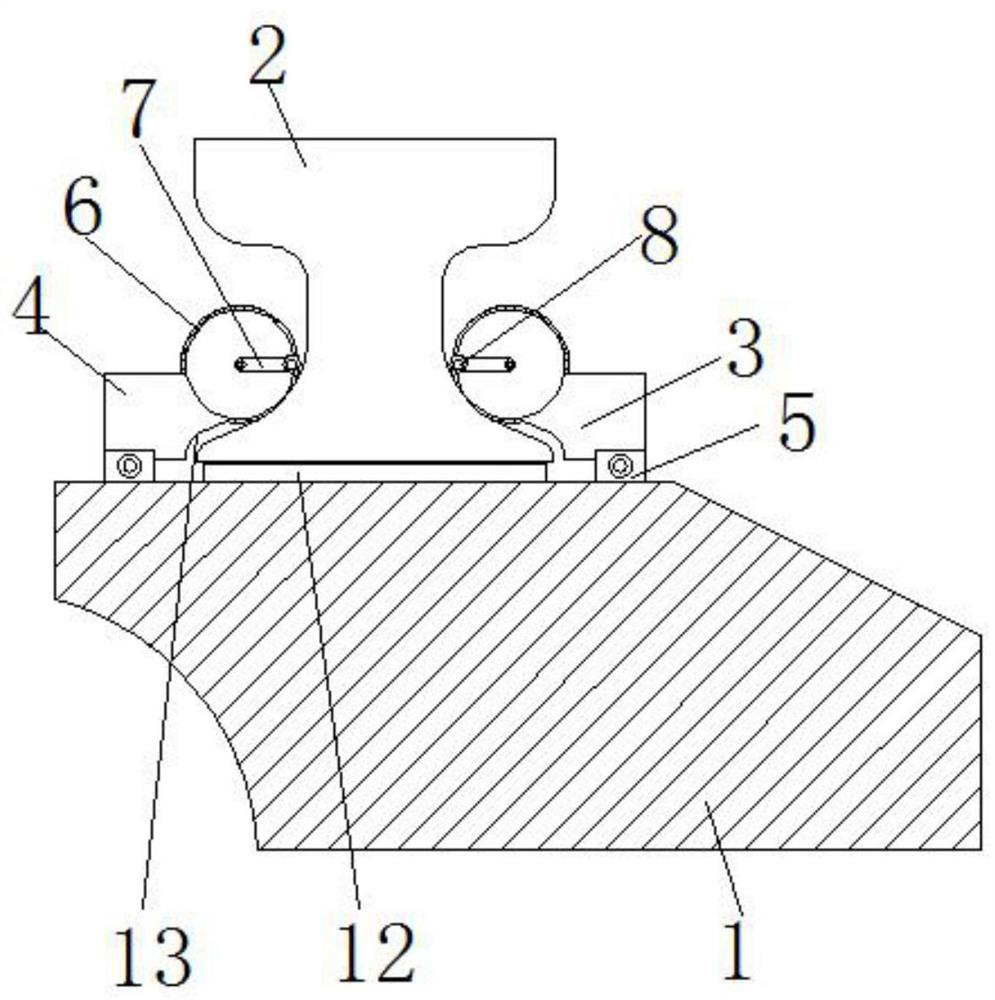

Embodiment 1

[0019] In Embodiment 1, the limit ball 8 can be replaced by a rotating roller, and the roller surface of the rotating roller can also be pressed against the side of the power transmission track 2 , and the rotating rollers on both sides can also form a clamping shape for the power transmission track 2 .

Embodiment 2

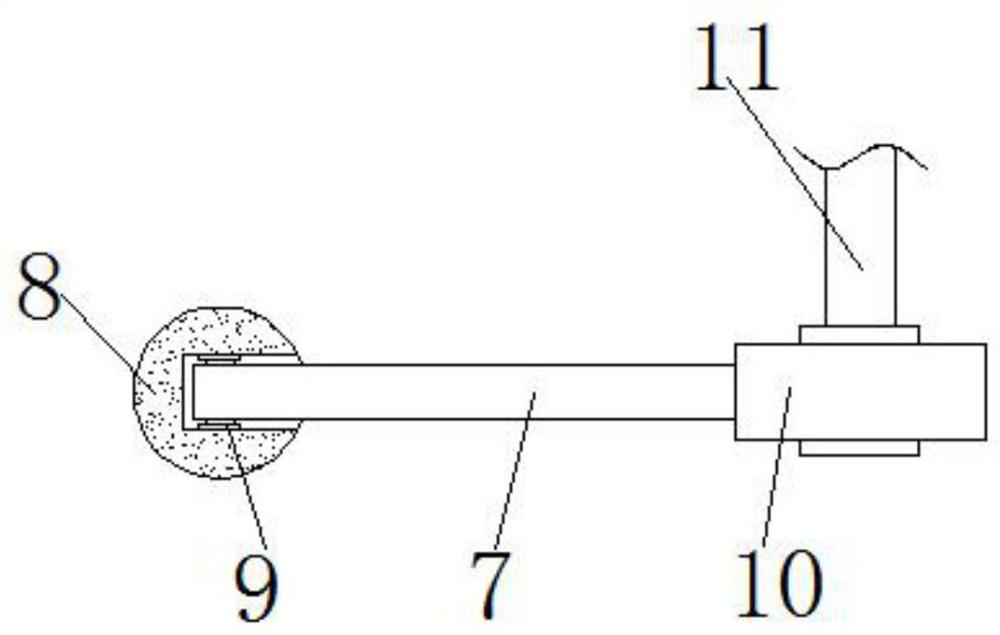

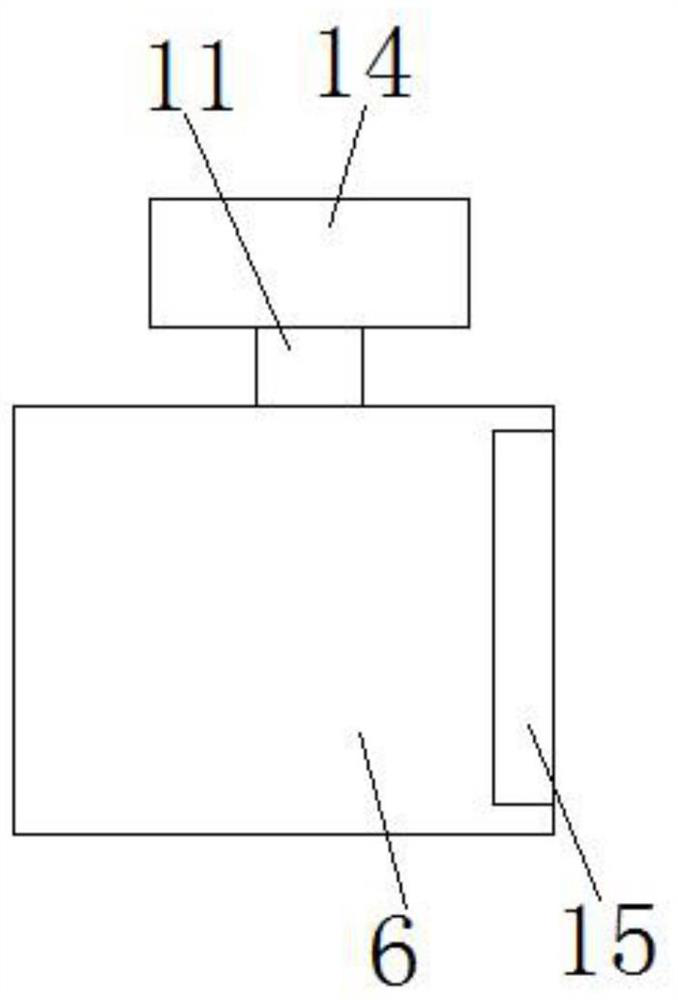

[0020] In the second embodiment, the motor 14 drives the movable arm 7 to rotate automatically, which can also be replaced by manual rotation. The purpose of rotating the movable arm 7 is to control the limit ball 8 at the end to slide to different positions.

Embodiment 3

[0021] In the third embodiment, the movable arm 7 is installed on the connecting seat 10 through the spring shaft, here, the drive shaft 11 becomes a manual adjustment handle, and the adjustment handle controls the rotation and deviation of the movable arm 7, while the spring shaft can ensure its reset.

[0022] Specific working process: both the first clamping block 3 and the second clamping block 4 can be rotated. When the power transmission track 2 needs to be installed or removed, it is only necessary to turn the clamping blocks on both sides outward. When the transmission track 2 is clamped by the clamping blocks on both sides, the clamping gap will be different, that is, the distance between the clamping block and the transmission track 2 is different, which will affect the tightness of the clamping. For this reason, Design the limit ball 8 again, the position of the limit ball 8 is adjustable, the limit block 8 can slide along the outer wall contour of the power transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com