Steel pipe discharging roller assembly line

An assembly line and roller technology, applied in the direction of conveyors, rollers, conveyor objects, etc., can solve the problems of steel impact rebound, steel pipe position inclination, difficulty in matching the horizontal relative position of grooves, etc., and achieve the effect of preventing rapid rolling impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

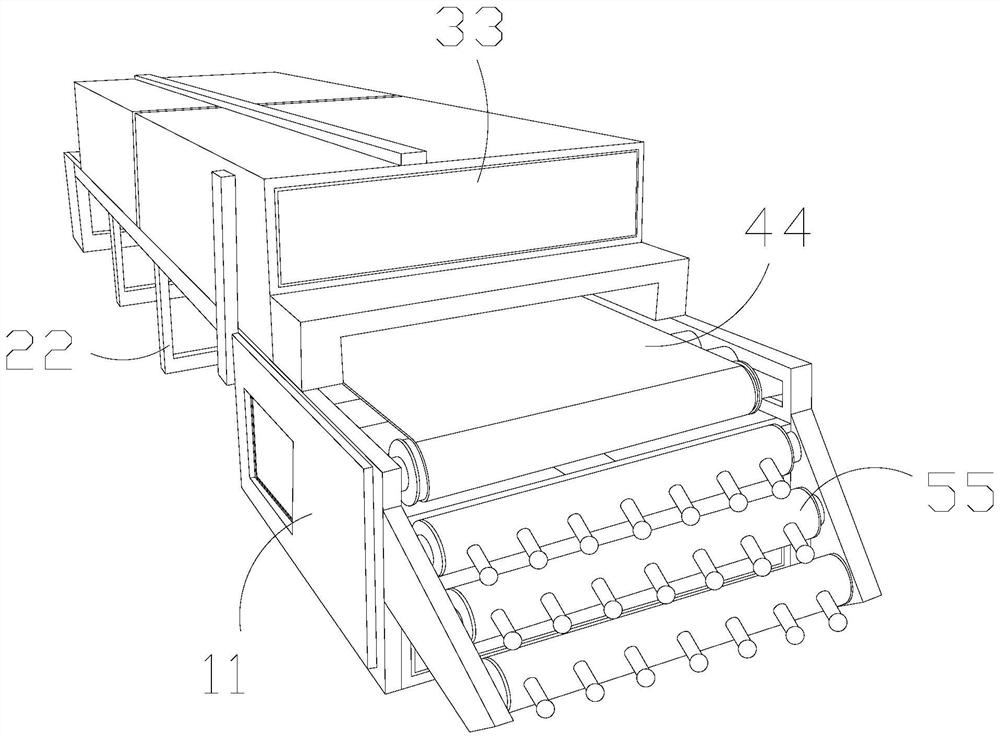

[0032] Append figure 1 Adherent Figure 6 Down:

[0033] The present invention provides a steel pipe lowering roller flow wire, which includes a control box 11, a support frame 22, a treatment tank 33, a roller strip 44, a dispensing cartridge 55, and the roller belt 44 is attached to the top of the control box 11, The support frame 22 is perpendicular to the bottom of the treatment case 33, the roller belt 44 being located inside the processing case 33, and the lower cartridge 55 is attached to the outer surface of the control box 11.

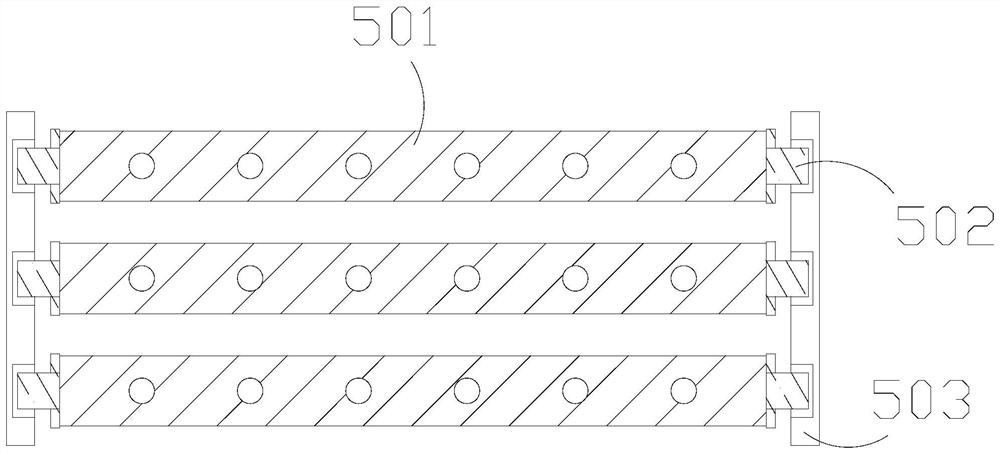

[0034] The lower cartridge 55 includes a roller body 501, a shaft 502, a side fixation plate 503, which is interposed inside the roller 501, and the rotary shaft 502 is connected to the side fixation plate 503.

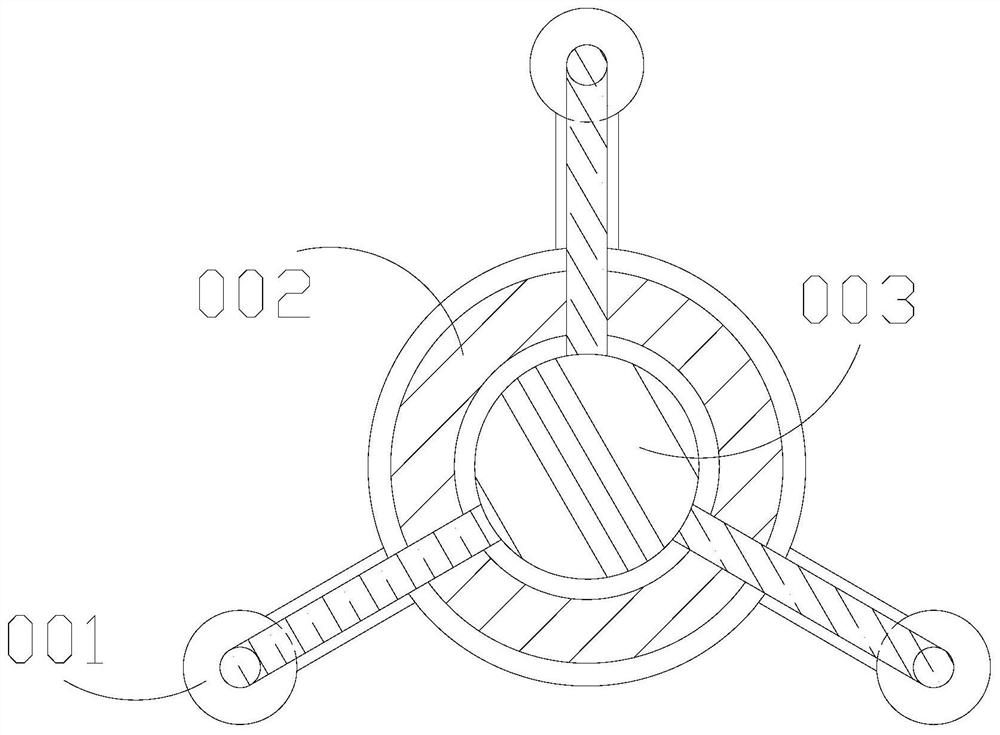

[0035] The roller 501 includes an extension 001, a clip 002, a medium column 003, and the clip 1002 is mounted between the two extensions 001, the clip 002 to the outer surface of the medium column 003, the The extension 001 is provided wi...

Embodiment 2

[0042] Append Figure 7 Adherent Figure 9 Down:

[0043] Wherein, the gluing ball E01 includes an outer gelatin layer 111, an inner empty groove 112, which is embedded inside the outer gelatin layer 111, the outer glue layer 111, made of rubber material, the inner air tank 112 is a vacant structure, and the inner space groove 112 is in force, and the internal space will be extruded.

[0044] Wherein, the inner empty groove 112 includes an extension body M01, an inner groove M02, a block M03, and the block M03 is mounted inside the inner groove M02, the inner groove M02 first end and the extension body M01, said The stretch M01 is provided with two, and when the bodies M01 are extruded in the engagement portion, when the gas is extruded around the body, the active action is expanded, allowing the gas to stretch space, the card When the block M03 is bent in the outer layer, it acts as a limitation.

[0045] Wherein, the extension M01 includes an arc strip S01, a inner clip S02, a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com