Ultralow-temperature sintered microwave dielectric material Ca2V2O7-H3BO3 and preparation method thereof

A microwave dielectric material, H3BO3 technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problem of insufficient microwave performance of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

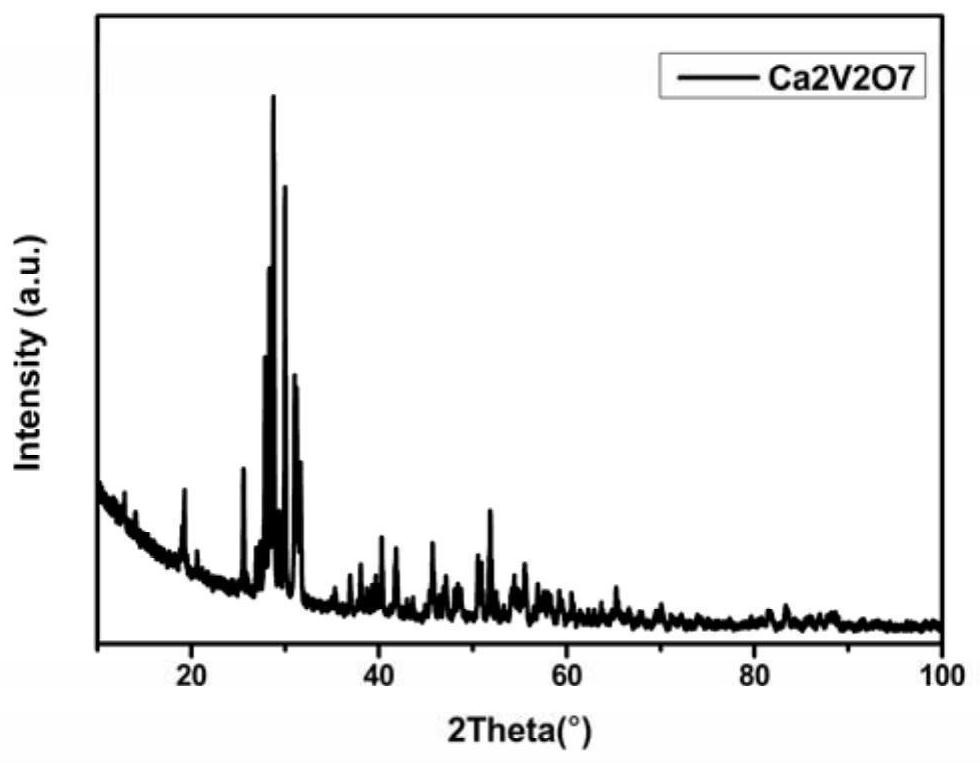

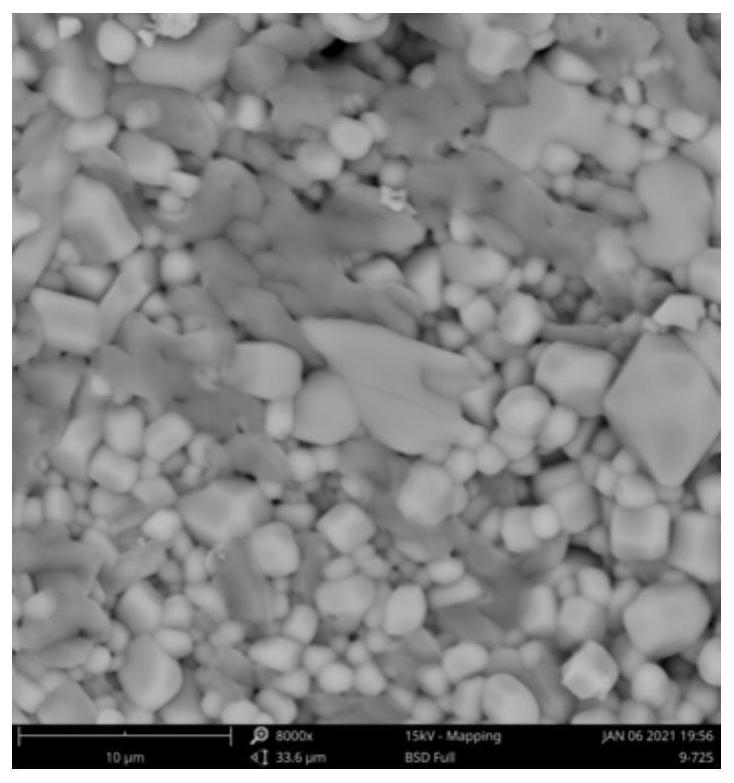

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0025] The present invention provides 6 embodiments altogether, and the ultra-low temperature sintered microwave dielectric material Ca of each embodiment 2 V 2 o 7 -H 3 BO 3 in, H 3 BO 3 compared to Ca 2 V 2 o 7 The mass percentage is x; the value of x, the core process parameters in the preparation method and the microwave dielectric properties of the prepared material are shown in the following table:

[0026] Numbering composition Sintering temperature Sintering time ε r

Q×f(GHz) τ f (ppm / °C)

Example 1 x=1 850 3 10.15 43348 -113.84 Example 2 x=3 725 3 10.93 36893 -115.36 Example 3 x=3 660 3 7.35 18749 -113.23 Example 4 x=5 725 3 11.11 37461 -115.97 Example 5 x=7 725 3 10.53 34605 -111.07 Example 6 x=9 725 3 10.36 37565 -106.56

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com