Traction tension machine for polyester staple fiber processing

A technology of polyester staple fiber and tension machine, which is applied in the field of tension machine, can solve the problems of increasing the processing cost of users, breaking the polyester staple fiber and reducing the processing efficiency of polyester staple fiber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

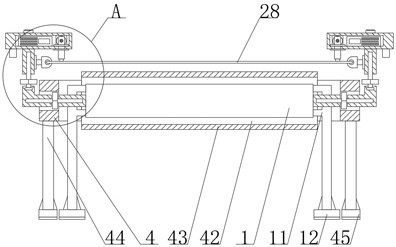

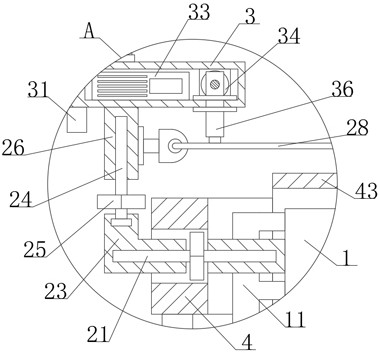

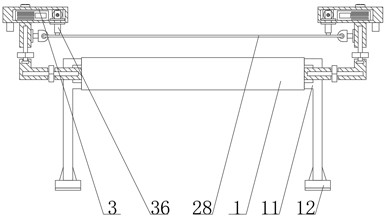

[0026] see Figure 1-6 , the present invention provides a technical solution: a traction tensioner for polyester staple fiber processing, including a mounting plate 1, a fixing piece 2 and a mounting seat 3, and the two sides of the mounting plate 1 near both ends are fixed by bolts Connected with a bracket 11, the mounting plate 1 can be effectively lifted away from the ground through the bracket 11. The middle parts on both sides of the mounting plate 1 are connected to the fixing parts 2 by bolts near the two ends. Screw rods 21 are threadedly inserted on both sides, and a connecting piece 23 is threaded at one end of the periphery of the two screw rods 21. The connecting piece 23 is in an L-shaped structure, and a drive member 22 is welded in the middle of the outer periphery of the screw rods 21. The driving part 22 is used as a rotation adjustment device for the screw rod 21 between the fixing part 2 and the connecting part 23, so that the connecting part 23 and the fixi...

Embodiment 2

[0028] see Figure 1-6, the present invention provides a technical solution: a traction tensioner for polyester staple fiber processing, including a mounting plate 1, a fixing piece 2 and a mounting seat 3, and the two sides of the mounting plate 1 near both ends are fixed by bolts Connected with a bracket 11, the mounting plate 1 can be effectively lifted away from the ground through the bracket 11. The middle parts on both sides of the mounting plate 1 are connected to the fixing parts 2 by bolts near the two ends. Screw rods 21 are threadedly inserted on both sides, and a connecting piece 23 is threaded at one end of the periphery of the two screw rods 21. The connecting piece 23 is in an L-shaped structure, and a drive member 22 is welded in the middle of the outer periphery of the screw rods 21. The driving part 22 is used as a rotation adjustment device for the screw rod 21 between the fixing part 2 and the connecting part 23, so that the connecting part 23 and the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com