Soft foundation replacement and filling structure and construction method thereof

A construction method and soft foundation technology, applied in infrastructure engineering, roads, roads, etc., can solve the problem of high cost, achieve the effect of reducing the overall cost of the project, reducing differential settlement, and shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

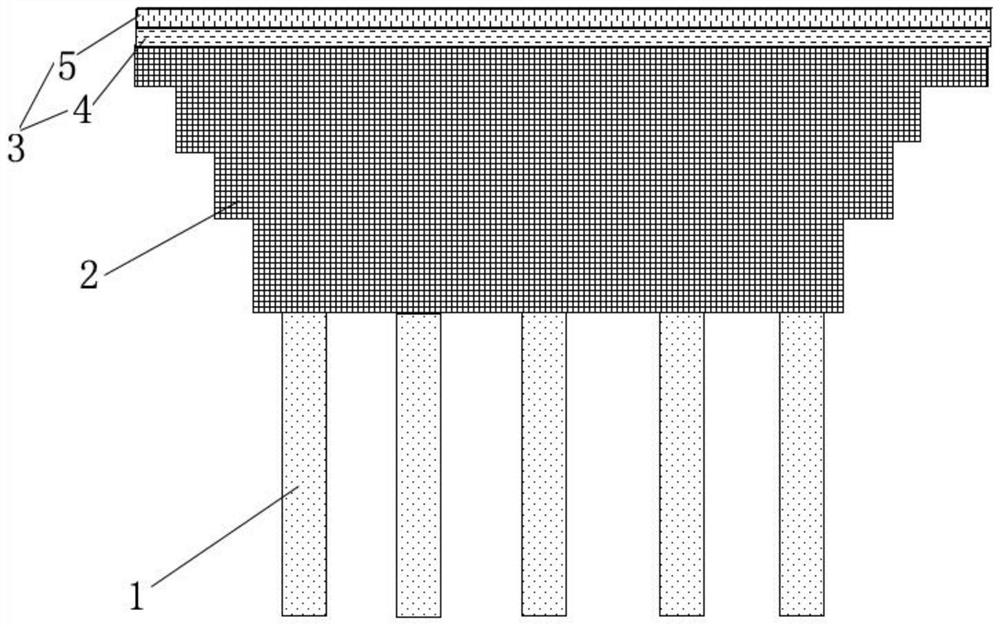

[0049] The construction method of the above-mentioned soft base exchange structure includes the following steps:

[0050] (1) The prototype stream base is excavated to form a primary subgrade processing layer 1;

[0051] (2) Prefabricated foam concrete, spare;

[0052] (3) Pouring foam concrete on the primary sub-path processing layer 1, forming a foam concrete layer 2; wherein the foam concrete layer adopts a layered construction process, 30 cm per layer;

[0053] (4) The pavement structure layer 3 is laid on the foam concrete layer 2, i.e., the soft base flux structure.

[0054] Among them, the foam concrete includes a weight of the following weight: 50 kg of waste generated during mineral crushing and screening process, 50 kg of gelling material; the preparation method is: (1) weigh the weight of the foam concrete; (2) Mineral crushing, waste produced during screening is mixed; (3) mixed or grinding the gelling material, sieving,

Embodiment 2

[0056] The construction method of the above-mentioned soft base exchange structure includes the following steps:

[0057] (1) Piling on the foundation to form a primary sub-processing layer 1;

[0058] (2) Prefabricated foam concrete and foam concrete blocks, spare;

[0059] (3) Pouring the foam concrete by foam concrete block 1, forming a foam concrete layer 2; wherein the foam concrete layer is a layered construction process, 100 cm per layer;

[0060] (4) The pavement structure layer 3 is laid on the foam concrete layer 2, i.e., the soft base flux structure.

[0061] Among them, the foam concrete includes a weight of the following weight: mineral crushing, waste and non-ferrous metal waste 148kg, ceiling material 2kg; preparation method: (1) Weigh the weight of the above foam concrete (2) Mix the mineral crush, the waste produced during the screening process and the non-ferrous metal waste residue; (3) mixed or grinding the gelling material, sieving,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com