3D visual scanning detection device and working method thereof

A technology of scanning detection and vision, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high price, high-precision three-coordinate measuring machine core components relying on imports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

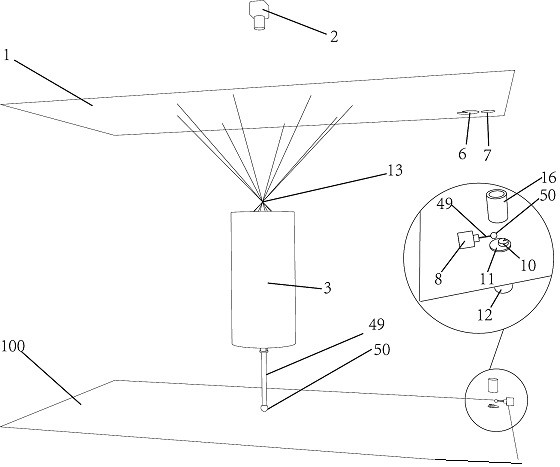

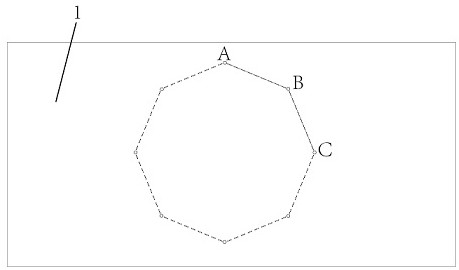

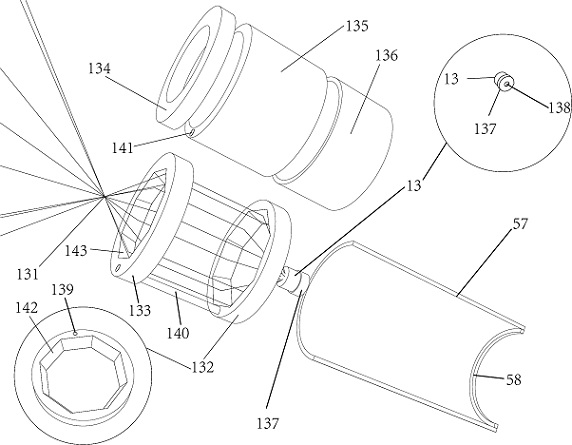

[0052] Such as Figure 1-8 As shown, a detection platform 100 is included, the detection platform is provided with a perspective hole up and down, a projection light source 12 is provided directly opposite the perspective hole frame under the detection platform, and a transparent platform 11 is provided on the upper surface of the detection platform directly above the perspective hole, so The back side of the transparent platform is embedded with a permanent magnet, and a calibration standard block 10 is magnetically attracted to the transparent platform. Measuring rod 49 is installed on the motor spindle, and measuring ball 50 at the end of the measuring rod is suspended above the transparent platform; a projection screen is set up directly above the detection platform, and the transparent platform and the projection screen are paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com