Lead-acid storage battery high-speed continuously-coated polar plate collecting device

A lead-acid battery and plate-receiving device technology, applied in lead-acid battery electrodes, electrode manufacturing, electrode collector coating, etc., can solve the problems of cards, many personnel needs, and irregularities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

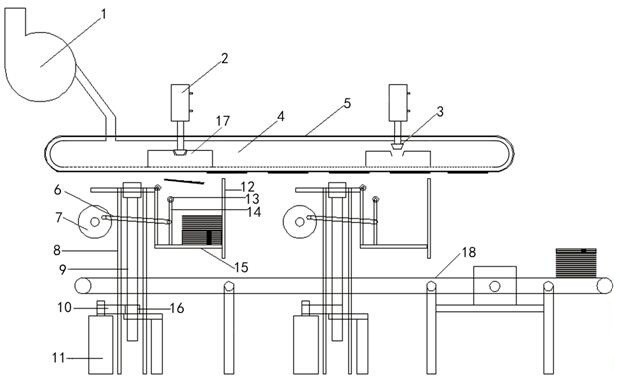

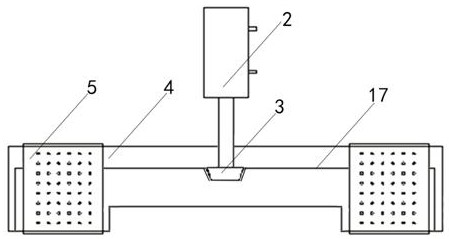

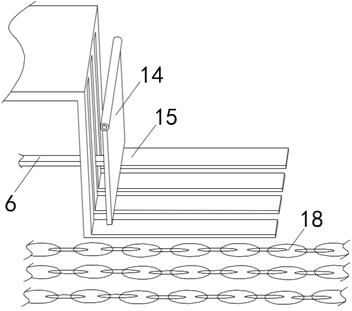

[0023] A high-speed continuous coating electrode plate collection device for lead-acid batteries, including a rotary adsorption transmission mechanism installed on the frame, two airflow blocking mechanisms and four sets of sheet collection mechanisms, in the rotary adsorption transmission mechanism, a negative pressure exhaust fan 1 It communicates with the empty suction sheet box 4, and the outer wall of the empty suction sheet box 4 is provided with two conveyor belts 5 with adsorption holes that rotate around it. The bottom surface of the suction sheet box 4 is densely distributed with through suction holes communicating with the adsorption holes. Suction hole cover 17 is installed on the inner bottom of suction sheet box 4, and suction hole co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com