Battery cell pole piece shaping device

A shaping device and pole piece technology, which is applied in battery assembly machines, secondary battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems that the battery pole piece cannot be installed inside the lithium-ion battery, the steps are cumbersome, and the work efficiency is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

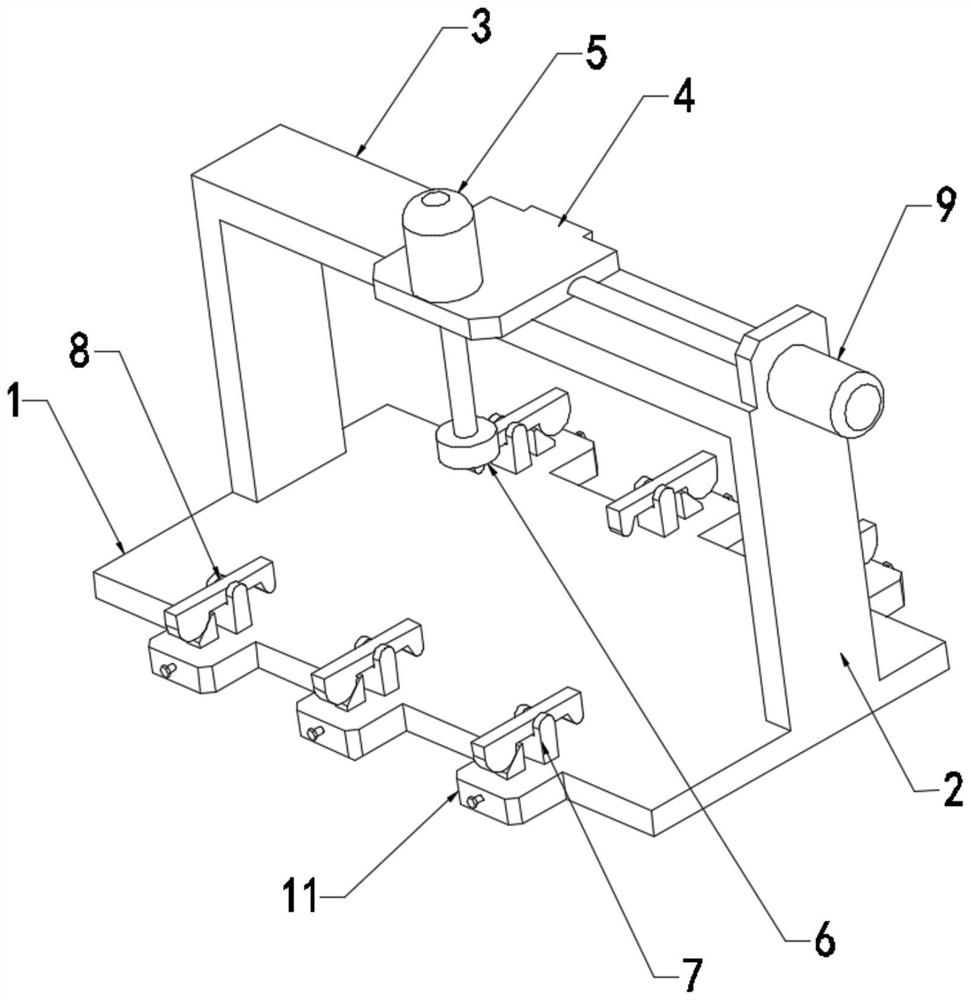

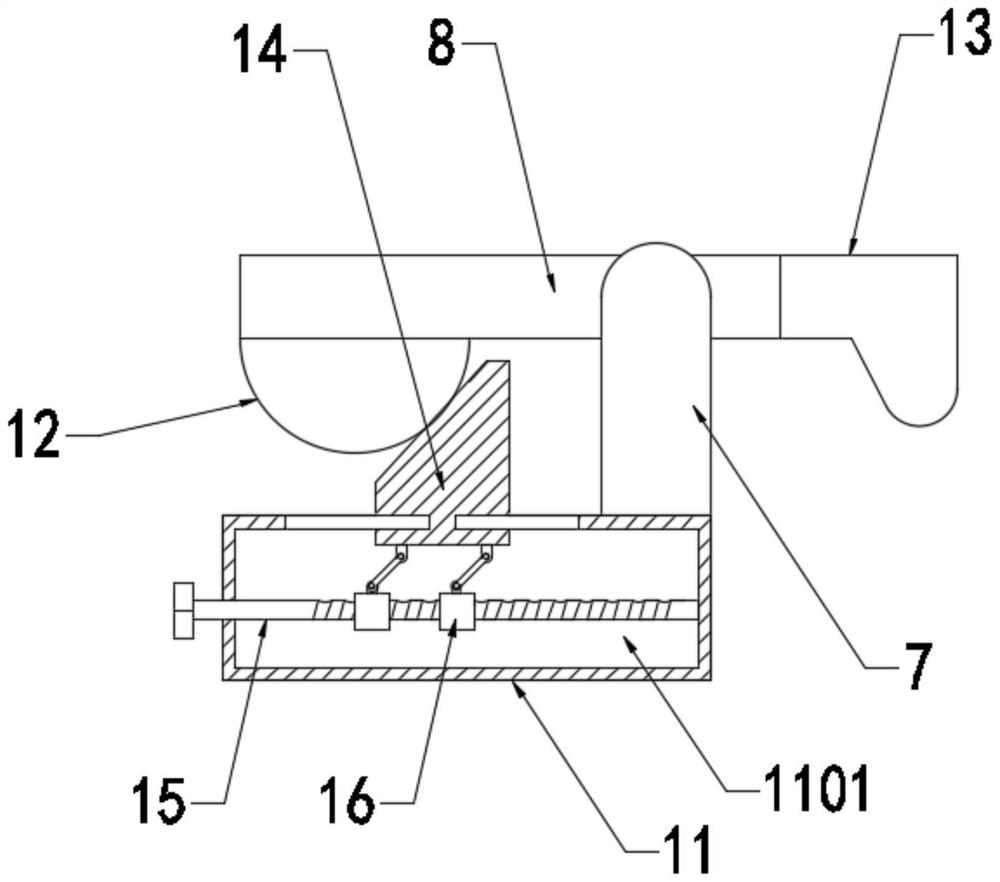

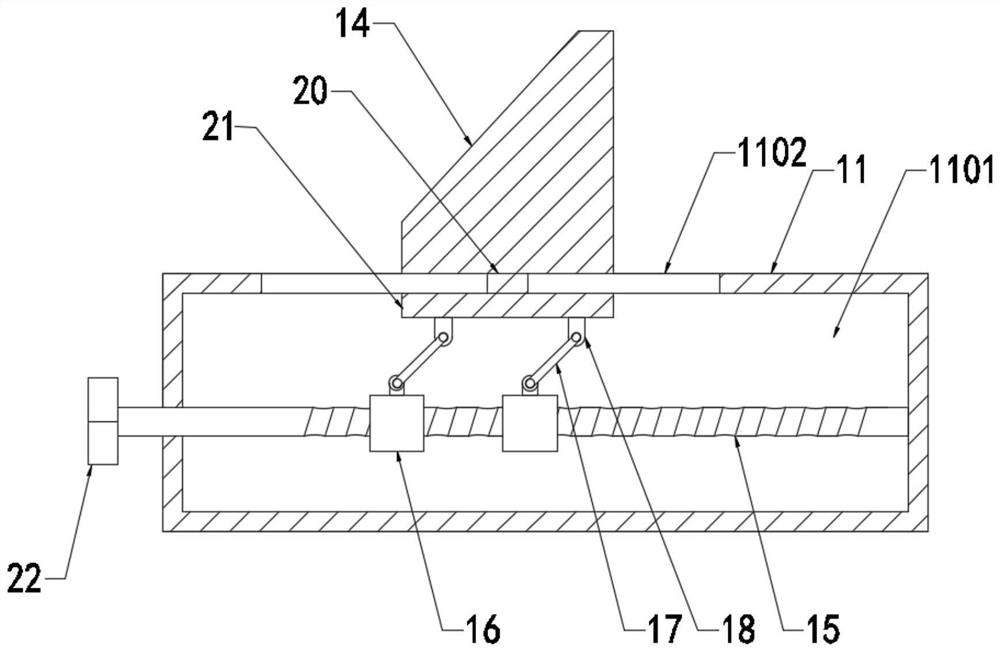

[0042] see Figure 1-7, The present invention provides a technical solution: a cell pole piece shaping device, comprising a shaping bottom plate 1, two ends of the shaping bottom plate 1 are fixedly connected with support blocks 2, the two support blocks 2 are fixedly connected with a flat plate 3, and the flat plate 3 is fixed on A sliding block 4 is slidably connected, the flat plate 3 is provided with a first driving mechanism that drives the sliding block 4 to move, a first cylinder 5 is fixedly installed on the sliding block 4, and a piston rod of the first cylinder 5 is fixedly connected in a vertical direction. The shaping block 6 that moves up, the first drive mechanism includes a second cylinder 9, the support block 2 is fixedly installed with a second cylinder 9, the piston rod of the second cylinder 9 is fixedly installed with the sliding block 4, and the first cylinder 5 is fixed by bolts Installed on the sliding block 4; a plurality of fixed blocks 7 and a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com