Copper sheet assembling mechanism of motor commutator

A technology of motor commutator and assembly mechanism, which is applied in the field of machining, and can solve problems such as difficult automatic assembly, uneven quality, and increased labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

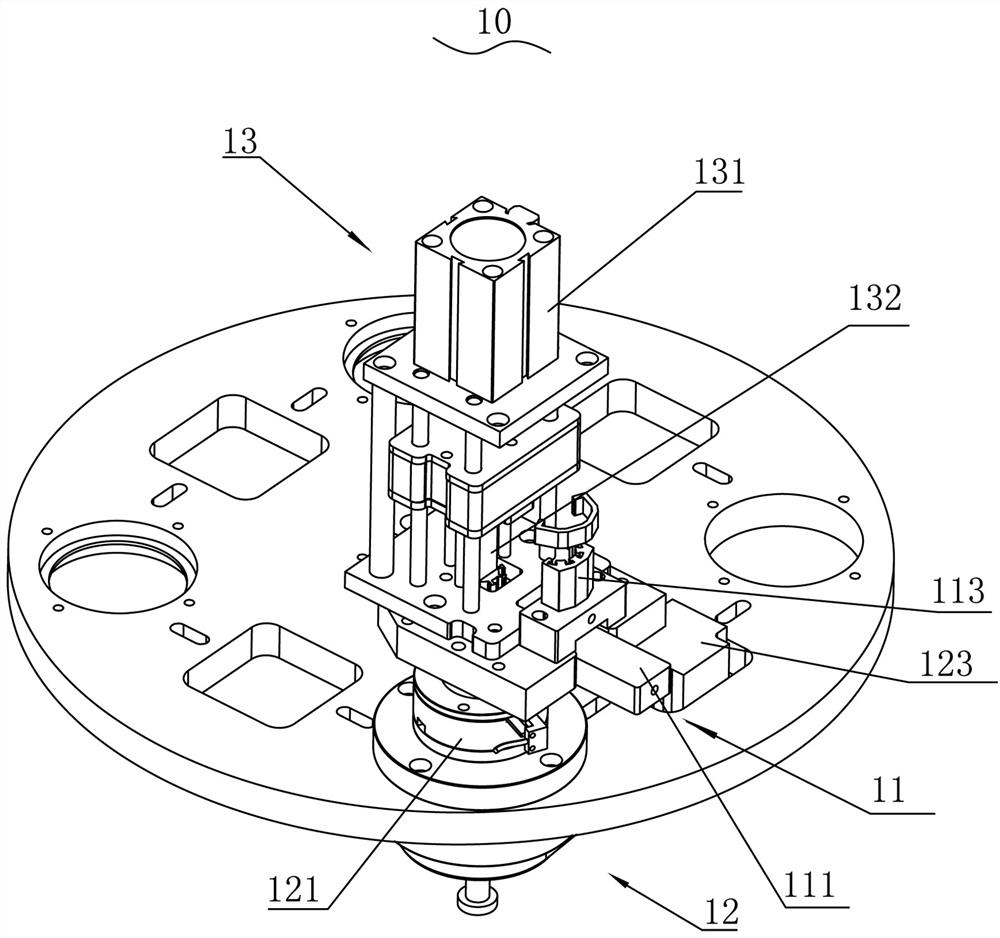

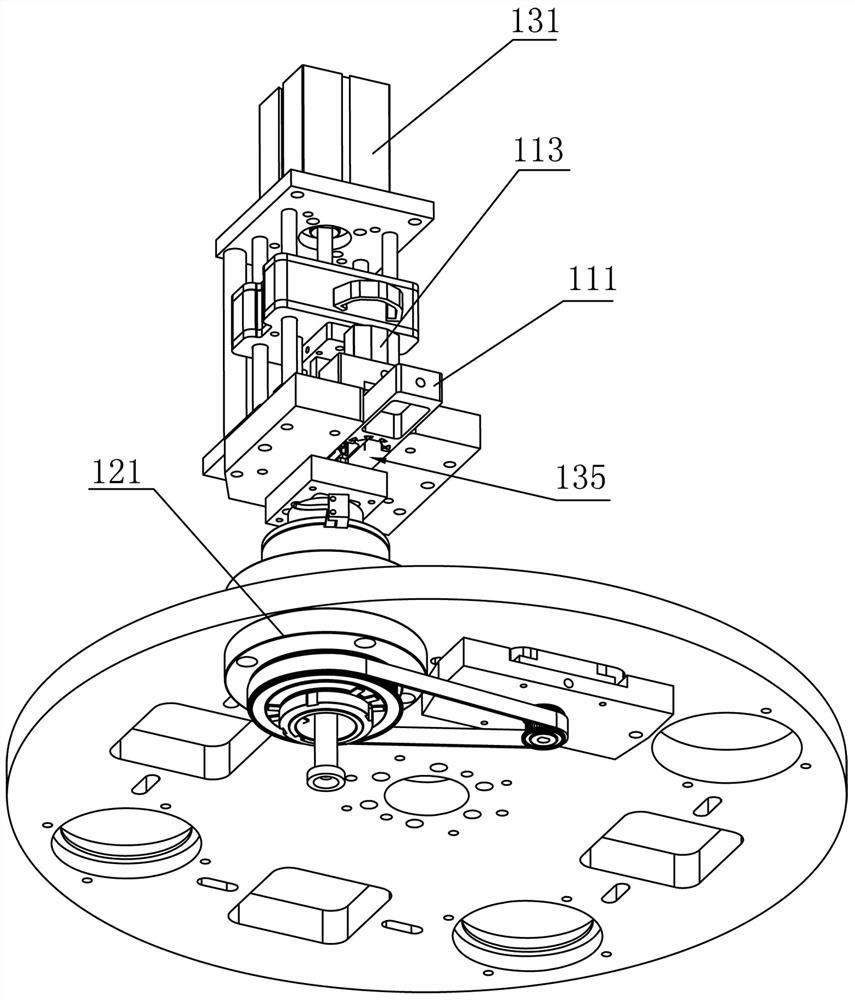

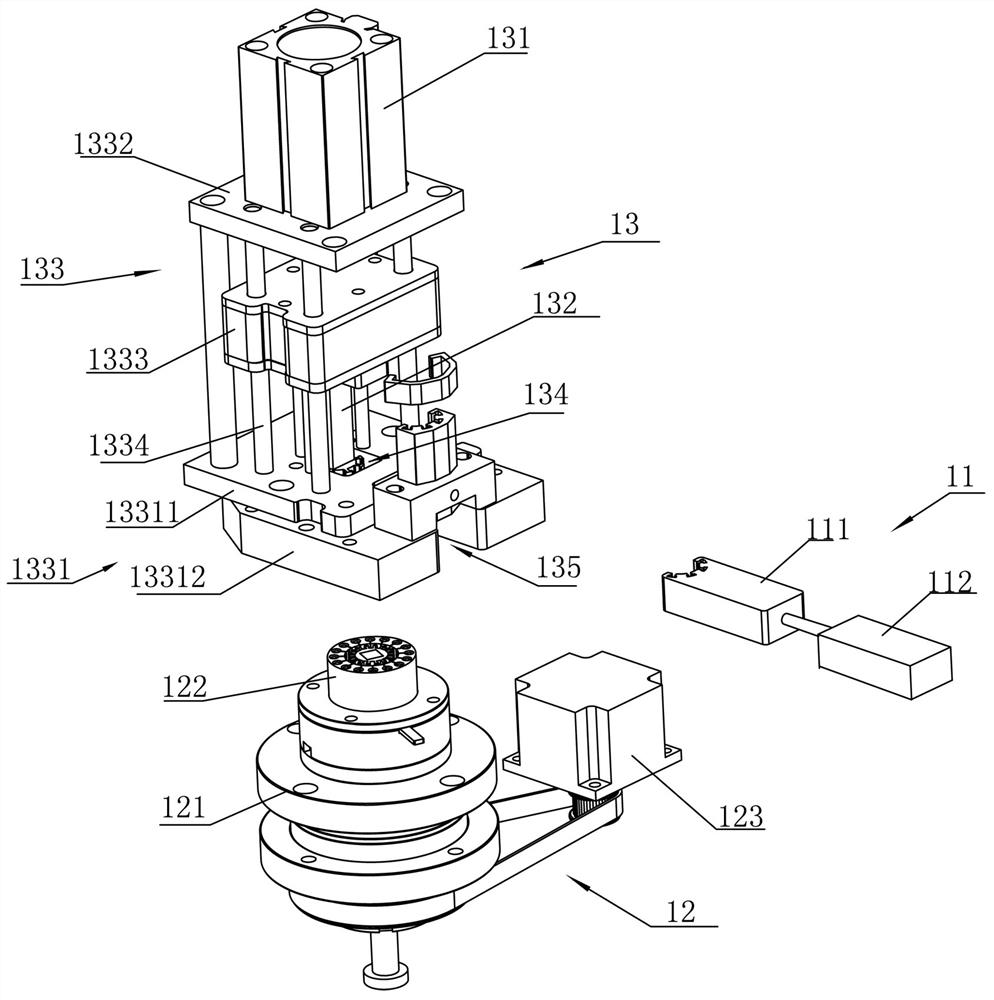

[0026] Figure 1 to Figure 10 , which is a preferred embodiment of a copper sheet assembly mechanism for a motor commutator provided by the present invention. Such as Figure 1 to Figure 10 As shown, the copper sheet assembly mechanism 10 of the motor commutator includes a copper sheet assembly 11 for receiving copper sheets, a copper sheet installation assembly 12 for installing copper sheets, and a copper sheet installation assembly 12 arranged above the copper sheet installation assembly for The copper sheet in the receiving assembly is pressed to the copper sheet pressing assembly 13 in the copper sheet installation assembly. After the copper sheet is transported in place by the external feeding mechanism, the copper sheet receiving assembly 11 receives the copper sheet 100 and moves the copper sheet 100 To the top of the copper shee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap