Black matrix substrate and display device equipped with black matrix substrate

A technology of black matrix and black matrix layer, which is applied in the direction of identification devices, lighting devices, instruments, etc., can solve the problems of not considering the composition of color filters, etc., and achieve the effect of improving display contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0060] (Black Matrix Substrate)

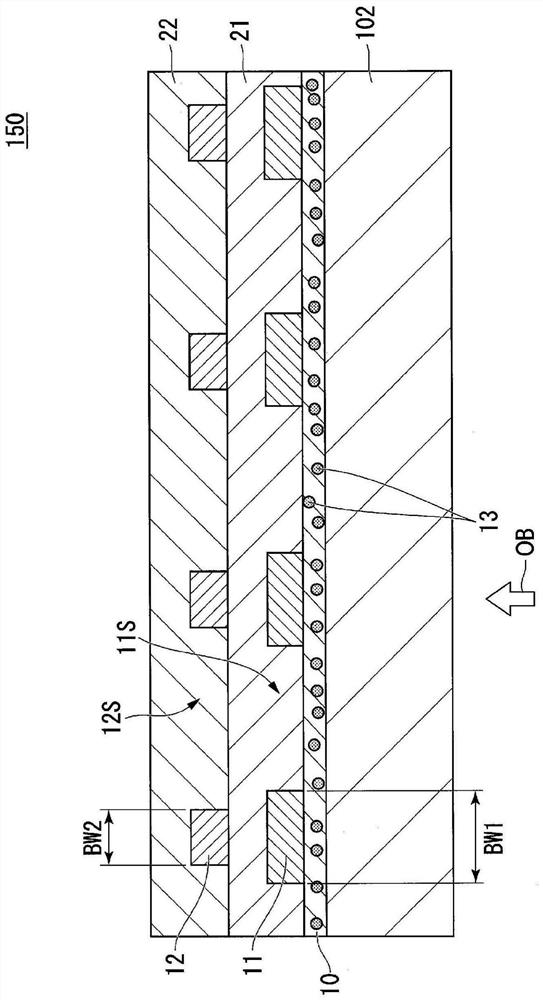

[0061] figure 1 It is a cross-sectional view partially showing the black matrix substrate of the first embodiment of the present invention.

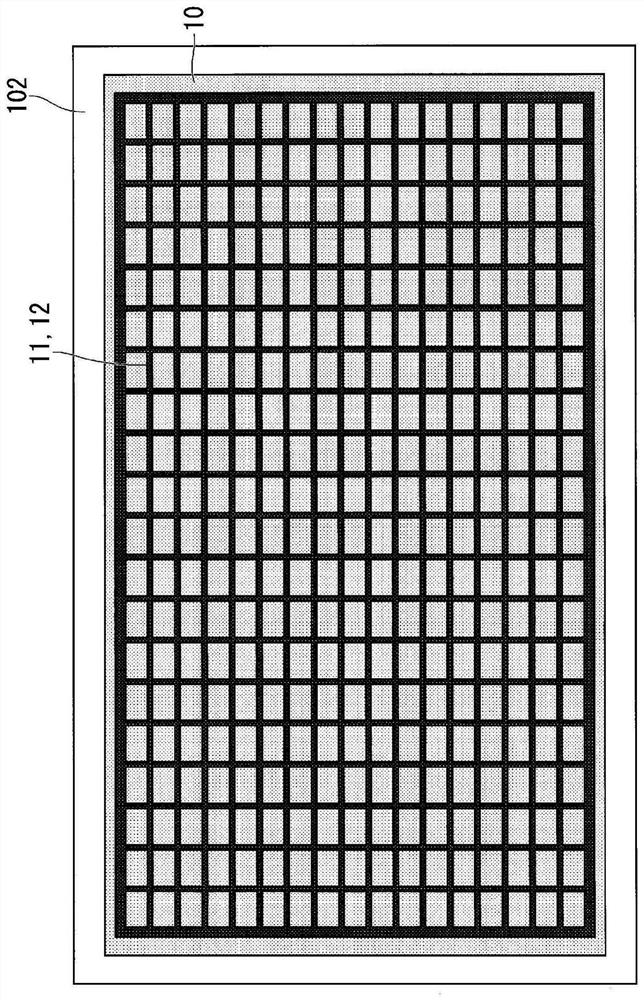

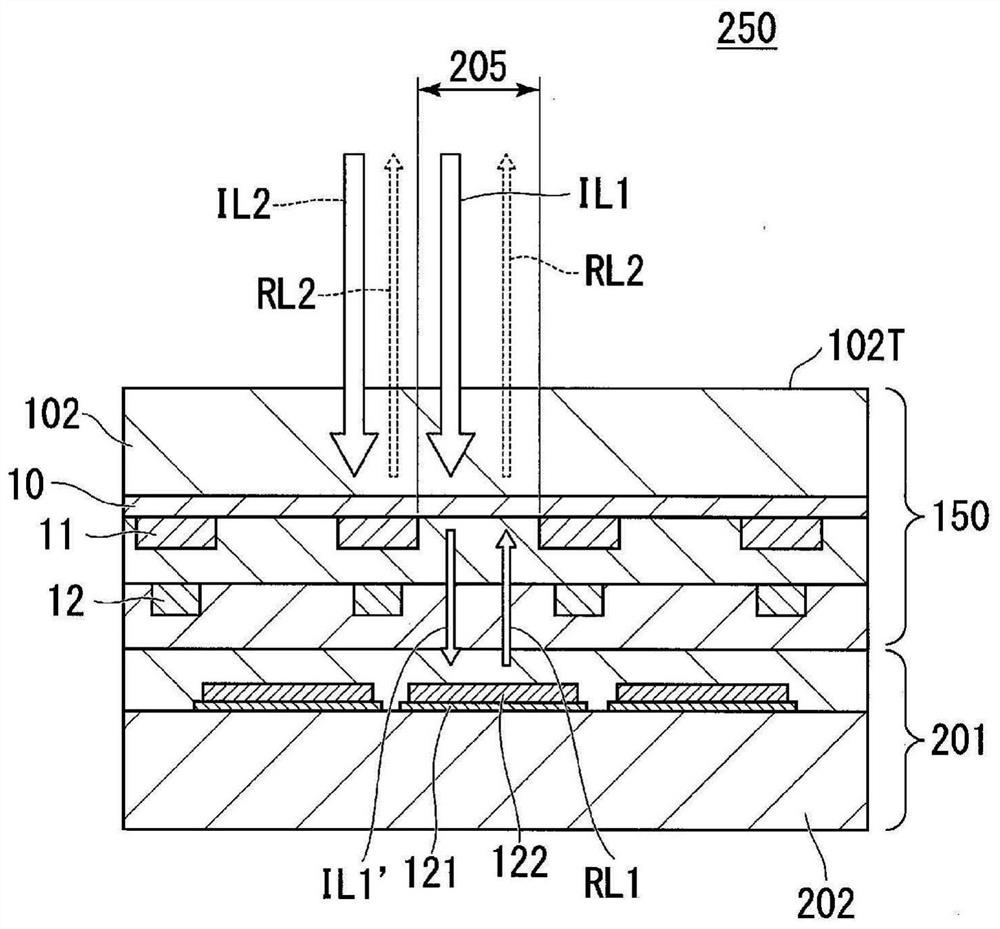

[0062] The black matrix substrate 150 has: a transparent substrate 102; a semi-permeable film 10 formed on the transparent substrate 102; The first black matrix layer 11 on 10; the first transparent resin layer 21 (transparent resin layer) formed on the semi-permeable film 10 in a manner covering the first black matrix layer 11; formed on the first transparent resin layer 21 and the second transparent resin layer 22 formed on the first transparent resin layer 21 in such a way as to cover the second black matrix layer 12 .

[0063] That is, the black matrix substrate 150 has a structure in which the semi-permeable film 10, the first black matrix layer 11, the first transparent resin layer 21, the second black matrix layer 12, and the second transparent resin layer 22 are sequentially stacked on the tran...

Deformed example 1

[0139] Figure 7 It is a cross-sectional view partially showing Modification 1 of the black matrix substrate according to the embodiment of the present invention. At the point that the semi-permeable film 10 uses a semi-permeable film to which no optically isotropic particles 13 are added, Figure 7 The black matrix substrate 550 shown with figure 1 The black matrix substrate 150 shown is different.

[0140] According to such a black matrix substrate 550, not only the same effect as that of the above-mentioned first embodiment can be obtained, but also because no particles 13 are added to the semi-permeable film 10, the structure of the semi-permeable film 10 becomes simple, which contributes to The cost of the black matrix substrate is reduced.

Deformed example 2

[0142] Figure 8 It is a cross-sectional view partially showing Modification 2 of the black matrix substrate according to the embodiment of the present invention. At the point of providing the colored layers of the red layer R, the green layer G, and the blue layer B, Figure 8 The black matrix substrate 650 shown with figure 1 The black matrix substrate 150 shown is different.

[0143] Each of the plurality of first pixel openings 11S of the first black matrix layer 11 has a colored layer CF. The colored layer CF is composed of a red layer R, a green layer G, and a blue layer B. The red layer R, the green layer G, and the blue layer B are disposed in the first pixel opening portion 11S in such a manner as to correspond to the three first pixel opening portions 11S.

[0144] In particular, the red layer R, the green layer G, and the blue layer B are provided in the first pixel opening 11S of the first black matrix layer 11 between the first transparent resin layer 21 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com