Flexible mounting structure of rotary blade and turning and pressing device

A technology for installing structure and rotary tiller, applied in the field of agricultural machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

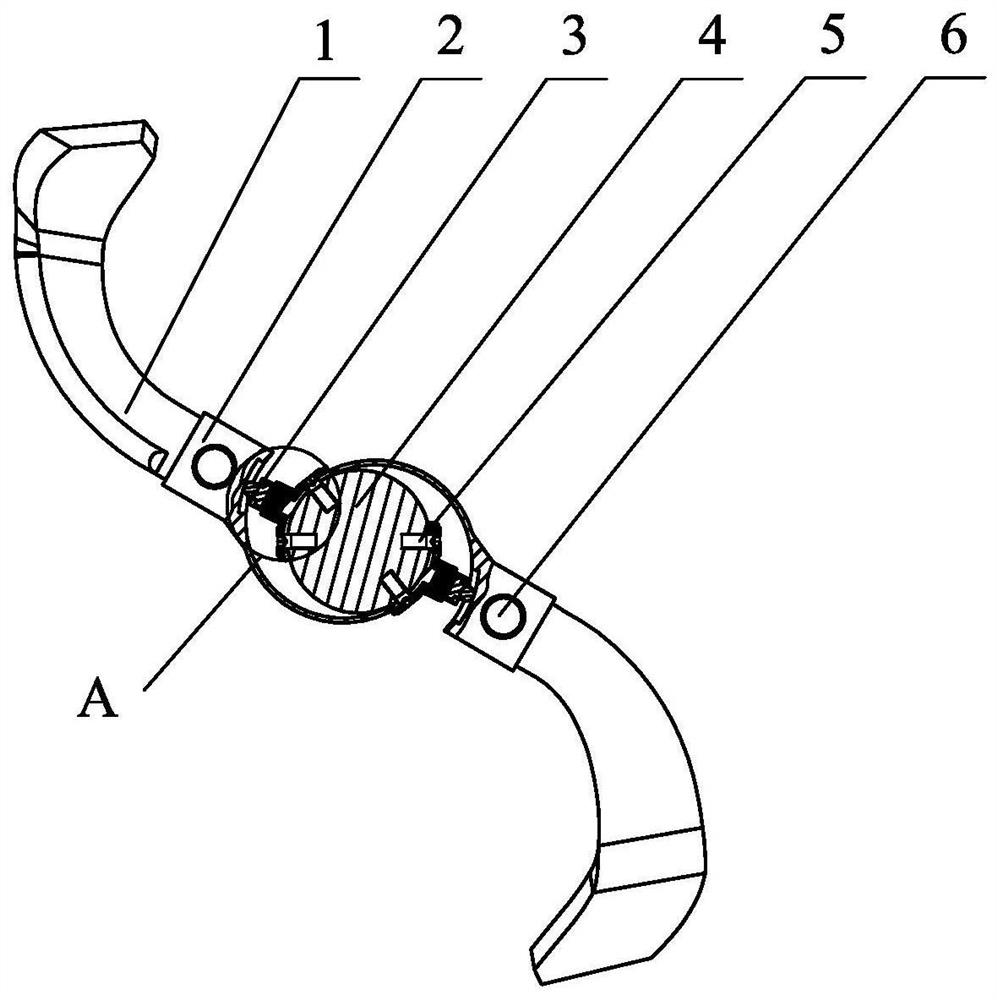

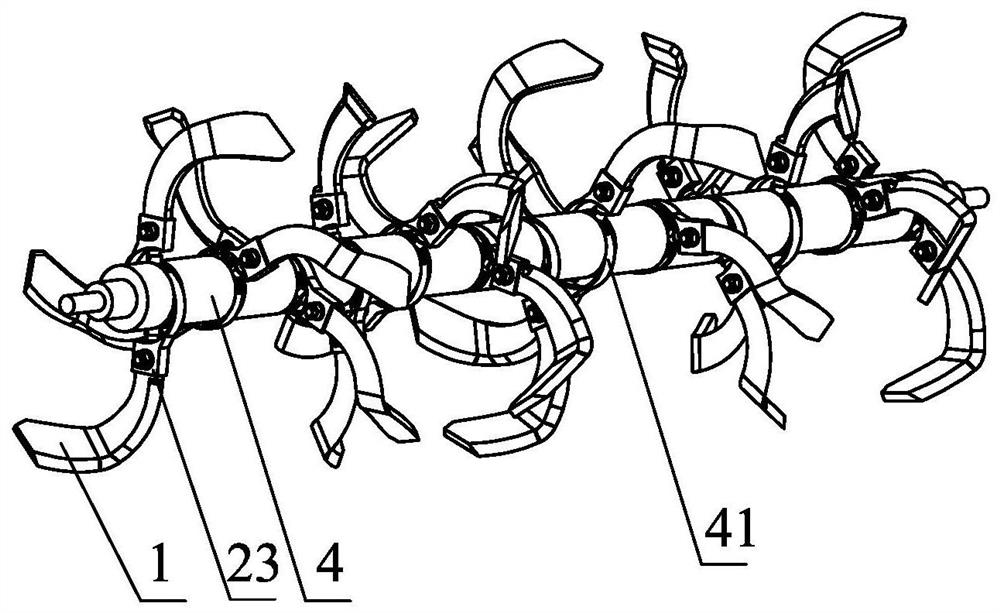

[0029] Example: such as figure 1 As shown, a flexible installation structure of a rotary tiller of the present invention includes a flexible installation knife seat 2 and a flexible buffer structure 3, and one end of the flexible installation knife seat 2 has a connection sleeve 23 structure that is matched with the connection end of the rotary tiller 1 , the other end has an arc-shaped installation end, and the arc-shaped installation end is provided with a slideway 21 near the connecting sleeve 23, and the corresponding other side has a boss 22, and the arc-shaped installation end surrounds the rotary blade installation shaft 4, the end with a boss 22 is connected to the installation shaft 4, and the flexible buffer structure 3 is connected between the boss 22 and the slideway 21 of the flexible installation knife seat 2 on the corresponding other rotary blade 1.

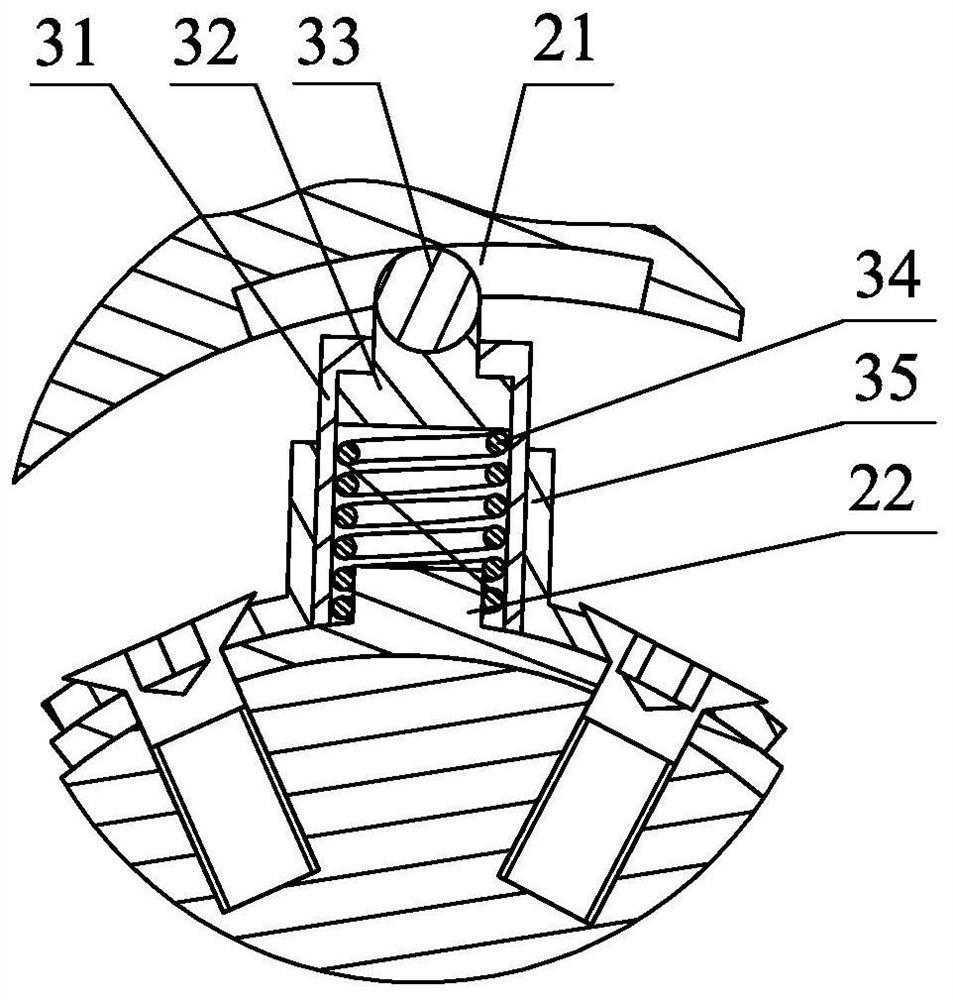

[0030] like figure 2 As shown, the flexible buffer structure includes a float 32, a float sleeve 31, a compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com