Grain drying and screening device

A screening device, grain drying technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve problems such as easy accumulation and accumulation of dryers, affecting grain drying effect and drying efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The contents of the present invention will be described below in conjunction with specific embodiments.

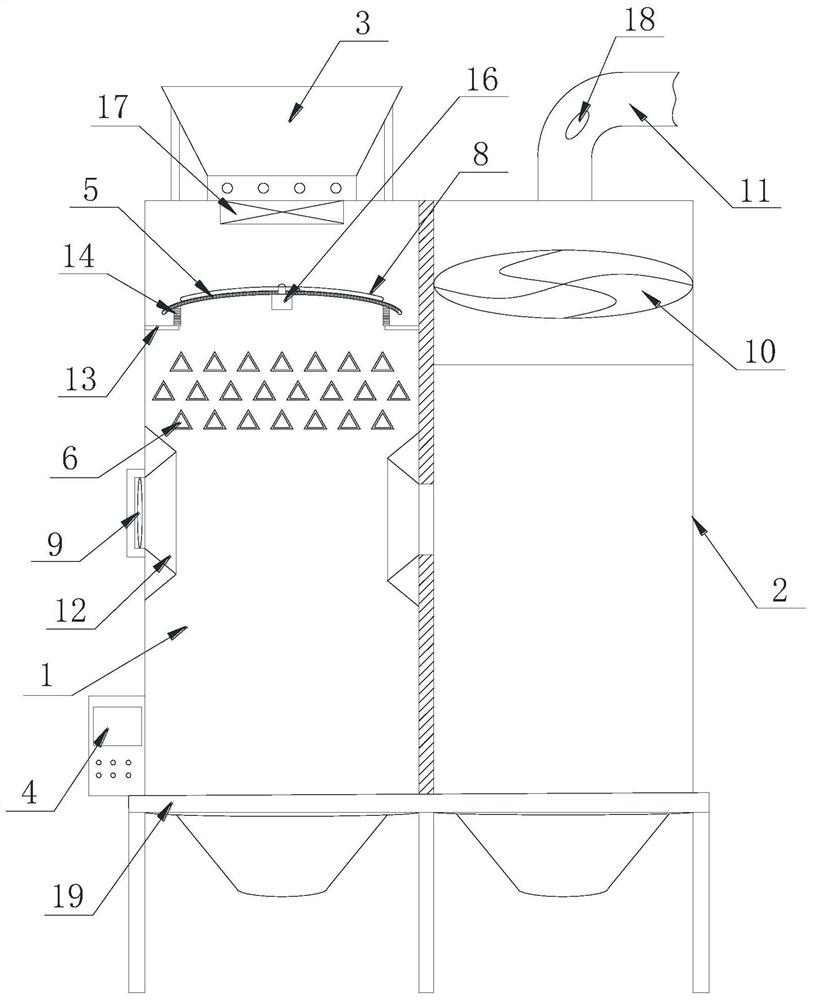

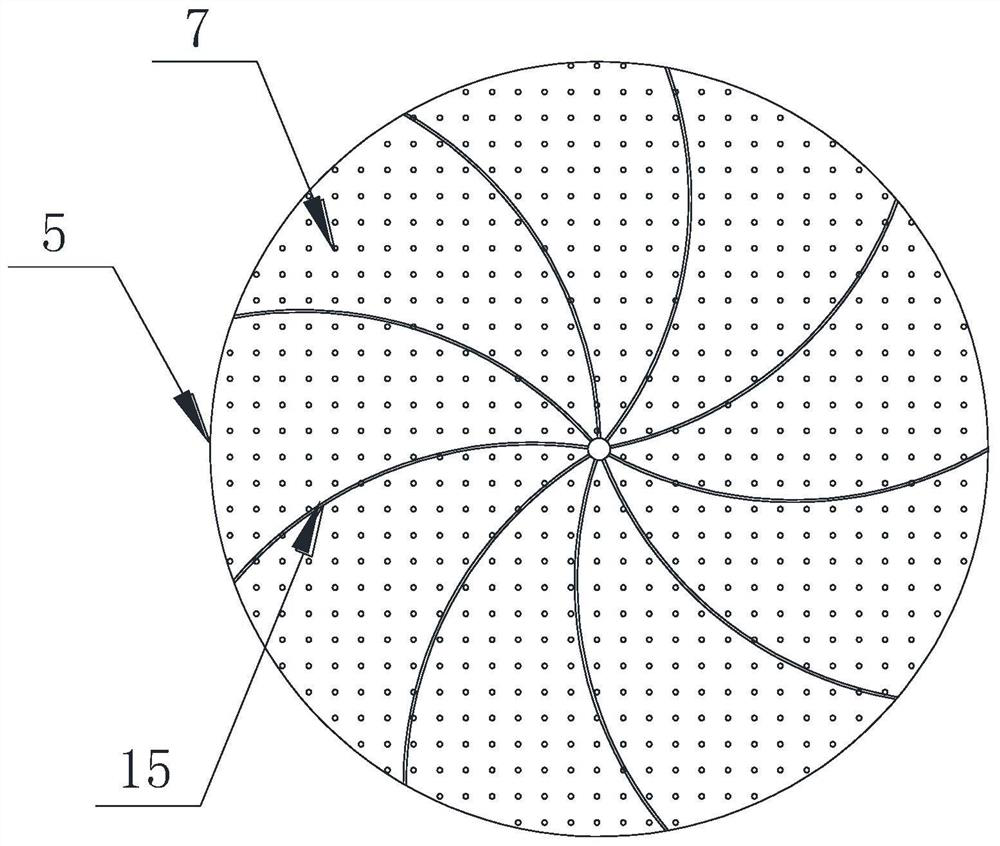

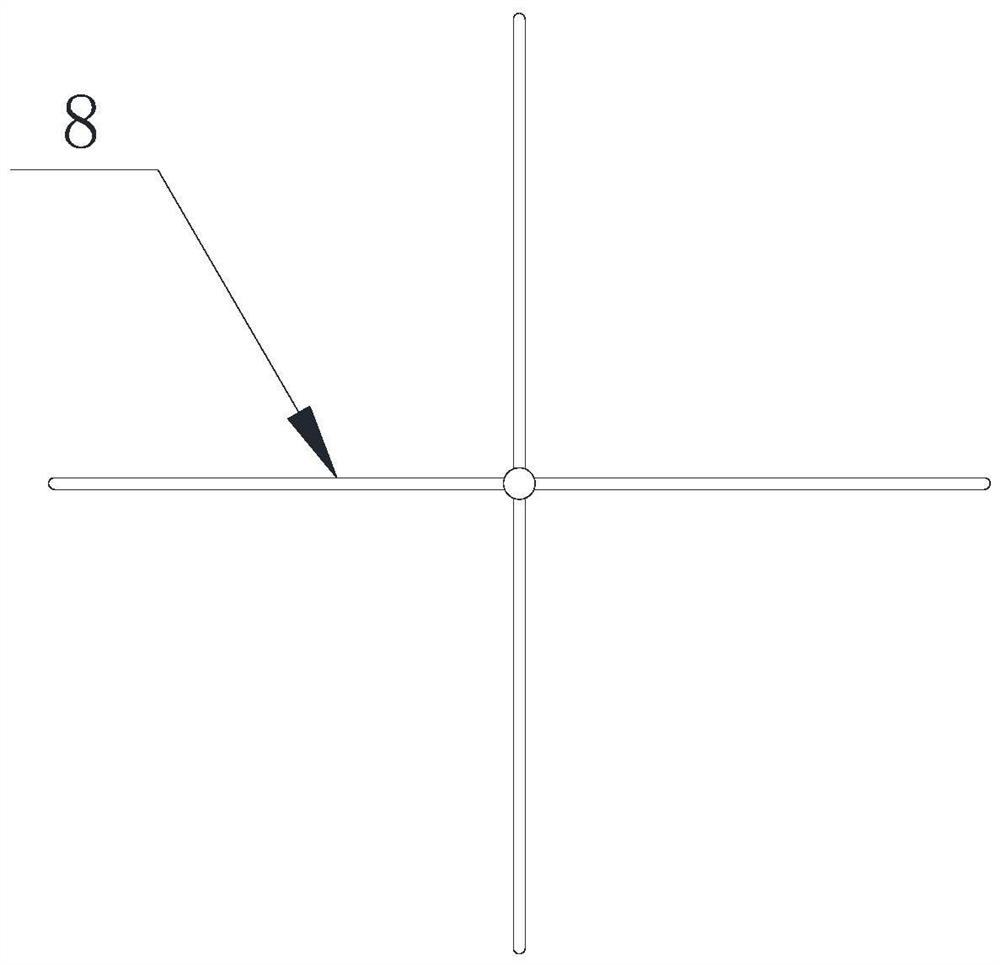

[0020] Such as figure 1 , figure 2 with image 3 As shown, a grain drying screening device includes a screening bin 1 and a murrent bond 2, the screen port 1 and a cylindrical cavity of the middle communication, screening 1 and division bin 2 The bottom is provided with a conical discharge opening, and the top of the screen is provided with a vertically mounted storage strip 3. The storage hopper 3 is connected to the screen 1, and the screen of the screen is provided with a smart control box 4, screening 1 The distribution tray 5, homogenesis 6 is provided, and the substrate disk 5 is an arcuate plate mounted on the upper portion of the screen, and the distribution disk 5 is uniformly provided with a grain through hole 7 and horizontally located in the storage hopper. At 3 positive, the upper surface of the substrate disk 5 is provided with an arc-shaped substrate rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com